BatX Energies' plant in India uses a hydrometallurgical process to extract critical materials such as lithium, cobalt, nickel and manganese from spent lithium-ion batteries.

The facility is capable of efficiently recycling all types of lithium-ion battery waste, including defective products from upcoming large-scale manufacturing plants.

The battery recycling plant follows the launch of BatX's first "black mass" manufacturing facility in Sikandrabad, Uttar Pradesh in 2022, and scaling up operations to commercial levels after a successful 21-month industrial trial.

“This transformational step in the downstream battery recycling value chain leverages BatX’s proprietary chemical process to extract high-purity critical materials tailored to specific applications and the lithium-ion battery industry,” the company said.

BatX Energies' new facility combines materials extraction with reusable energy storage applications, supporting batteries at every stage of their lifecycle.

The plant reportedly achieves low energy consumption through zero-emission and zero-waste processes.

“This pioneering approach not only makes critical materials for electric vehicle batteries more cost-effective and accessible, but is also fully compliant with the Indian Ministry of Environment and Forests’ Battery Waste Management Rules, 2022,” BatX said.

(According to PV-Magazine)

Source: https://vietnamnet.vn/an-do-co-nha-may-tai-che-pin-lithium-va-chiet-xuat-khoang-san-2358568.html

![[UPDATE] April 30th parade rehearsal on Le Duan street in front of Independence Palace](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/18/8f2604c6bc5648d4b918bd6867d08396)

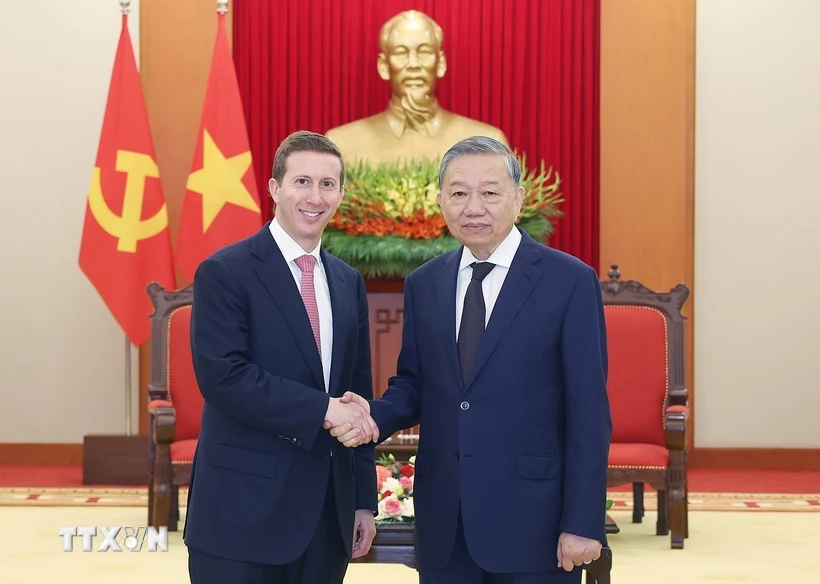

![[Photo] Prime Minister Pham Minh Chinh receives Mr. Jefferey Perlman, CEO of Warburg Pincus Group (USA)](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/18/c37781eeb50342f09d8fe6841db2426c)

Comment (0)