According to Business Insider , the startup CarbonScape produces synthetic graphite by heating waste from wood production through a pyrolysis process to create biochar. This material is then crushed and converted into raw graphite, which CarbonScape says is “a more sustainable option.”

CarbonScape uses leftover wood chips to produce graphite

“Our mission is to decarbonize the battery industry,” said CarbonScape CEO Ivan Williams. “That also solves a number of other problems, including localizing the supply chain.”

Producing a viable alternative to graphite is increasingly important for Western countries to replace the LFP (lithium, iron, phosphate) batteries that many electric vehicles use and avoid dependence on a single supply chain source, avoiding any potential disruptions to the supply chain in the future.

Some critics have questioned CarbonScape’s idea, saying it requires too much wood chips and is not as cost-effective as graphite. Still, the company received $18 million in funding from European forest products company Stora Enso earlier this year, opening the door to supplying the new technology to Europe. Hong Kong-based battery maker Amperex Technology has also invested in the company.

It is known that electric vehicle production is increasingly expanding globally. Therefore, the search for sustainable battery material sources is receiving increasingly strong support to meet the carbon reduction trend that the world is aiming for.

Source link

![[Photo] Prime Minister Pham Minh Chinh meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/893f1141468a49e29fb42607a670b174)

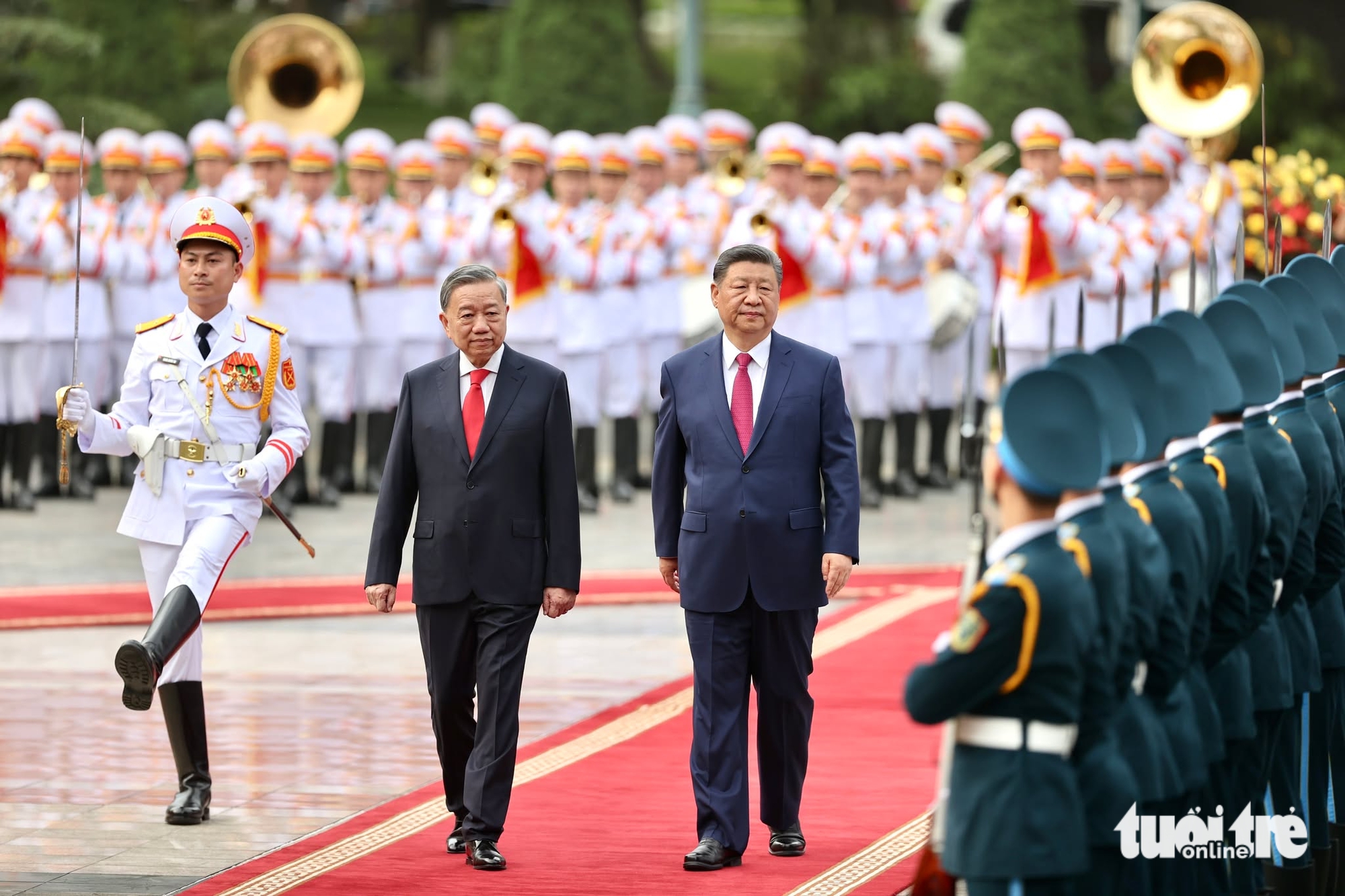

![[Photo] Reception to welcome General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/9afa04a20e6441ca971f6f6b0c904ec2)

![[Photo] National Assembly Chairman Tran Thanh Man meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/4e8fab54da744230b54598eff0070485)

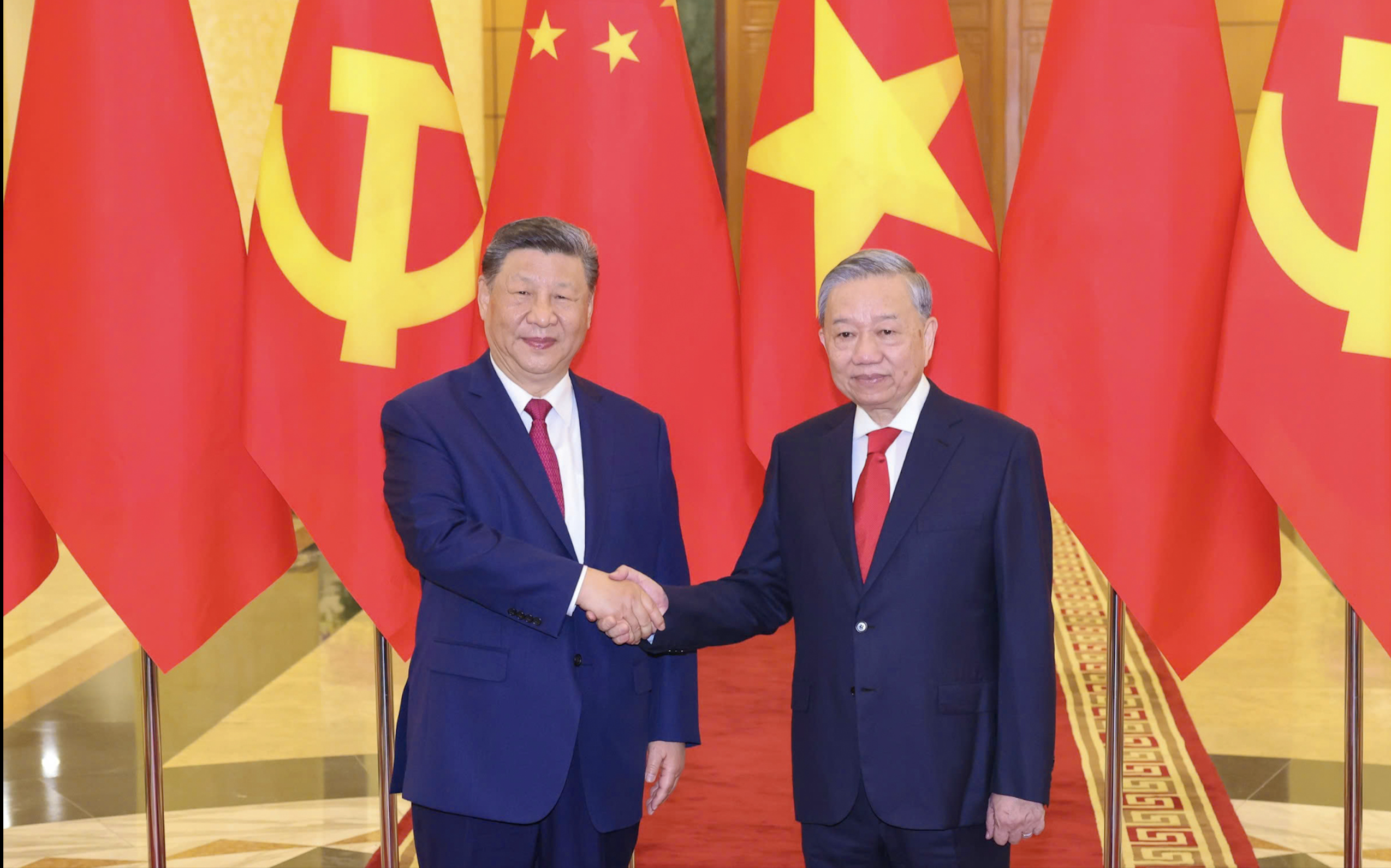

![[Photo] General Secretary To Lam holds talks with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/b3d07714dc6b4831833b48e0385d75c1)

Comment (0)