Possessing a relatively closed, calm sea area, stable water temperature all year round and little pollution or influence from passing boats, that is a natural advantage for Van Don to develop aquaculture in general, oyster farming in particular. Bavabi Oyster Shred (Van Don district) is the only product ranked 5-star OCOP by Quang Ninh province in 2016, is a typical start-up unit of Quang Ninh province, received a certificate of merit from Quang Ninh province for its outstanding achievements in organizing the implementation of the project "Quang Ninh province - one product per commune and ward".

In Quang Ninh, there are more than 450 households raising oysters with an output of nearly 20 thousand tons per year. Using the modern farming method of hanging rafts helps increase the output by 1.4 times compared to farming on concrete or fiber cement substrates. The households' rafts are located in places far from residential areas and factories, far from waterway traffic; the water in that area must be clear, clean, and have little wind and waves to ensure a food source, from which the oysters can grow healthy and of good quality.

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 1](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/83e6bc7f4fed4be3af1e136fa3dbfa4f) |

Milk oyster floss is a product made from fresh oysters with very high nutritional value. It is a specialty dish of Quang Ninh. Van Don island district is considered an "oyster granary" with an annual output of nearly 20 thousand tons, which is the main source of raw materials for producing oyster floss. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 2](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/39fafb45d0b4438d97096e7a3255e759) |

Oyster production and farming areas of oyster businesses and enterprises in Bai Tu Long Bay (Quang Ninh) seen from above. |

The production process that creates the Bavabi oyster floss brand At Quang Ninh Seafood Production and Trading Company Limited (Bavabi), after being transferred to the factory, the oysters will be quickly cleaned of parasitic algae and washed through an ozone tank. Then, under the skillful hands of coastal women, the oysters are gently and firmly separated so that the shells are not broken, keeping the oyster meat intact, without impurities due to broken oyster shells. The oyster meat is washed many times with diluted salt water to clean the slime and then put into the stir-fry machine.

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 3](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/3d8f3b00f8b6456ab9c16dd7ac8f4853) |

| During the oyster farming process, farm owners send water and oyster samples to the institute for testing every 2 months. After 4-5 months, the harvest begins. With abundant and local raw materials, many oyster chain models have been developed. With the participation of people, purchasing enterprises and processing enterprises... Through the chain, many quality products from oysters have been provided to the market. Among them, Quang Ninh milk oyster floss is very popular. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 4](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/e616b12767704368b0d68ea614957b80) |

| Choose oysters that meet the standard size, about 8-9cm. The steps are to thoroughly clean the shell, separate the oyster shell properly so that the oyster intestines do not break, wash the oyster intestines with diluted salt water to clean sand, shells... |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 5](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/d3ae552d00da4e7999c1da022452bec6) |

| After being carefully selected and meeting standards, oysters will be washed with salt water and RO water. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 6](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/c5883a8ee2ad4eedb8dc56ed5cc1a6f6) |

| In addition, the entire Bavabi oyster floss processing process uses semi-automatic machinery, ensuring food safety and hygiene. In particular, because no preservatives are used, the oysters after being canned must be put into a sterilization process at a temperature of 120 degrees Celsius. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 7](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/61ac825b968c49c4970679b6d84bfe84) |

| This step helps preserve oysters longer without the need for preservatives. At the same time, it avoids the attack of bacteria and mold from the outside environment. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 8](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/261d261249ad478198ad3957b4743c5b) |

| All these steps are done by machine, so it ensures food safety and hygiene and does not lose nutrients in oyster meat. The product has a shelf life of up to 12 months, without needing to be refrigerated. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 9](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/80a02063c0ea43ccafd1f058da846b84) |

| Oyster floss is packed into jars and sterilized for 4-5 minutes at 150 degrees Celsius, then labeled and transported to the point of consumption. During the process of making floss, workers must wear sterilized work clothes, gloves and masks. Machinery and tools such as basins and trays are all cleaned before and after use. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 10](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/06e9e45daaeb483e80fff0020fcbdf9a) |

| Workers packing Van Don oyster floss |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 11](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/cb77f189eb6b47edb53650cd73e047a6) |

| Bavabi's modern machinery system to create stable quality oyster floss products. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 12](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/6bcfdfbb789e454c97d89114d4a18276) |

| After being bottled and weighed with an electronic scale, the oyster floss jars are sterilized for 4-5 minutes at 150 degrees Celsius. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 13](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/29e6dc55cdca4ca7ba8c8f1b8d0e8797) |

| The final step in processing oyster floss is to bottle it, label it, and wait for it to be transported to the point of consumption. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 14](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/6014c2f200394bd9b48ded303a0ec207) |

| Van Don oyster floss product has been certified as a 5-star OCOP product since 2016, becoming a Vietnamese brand reaching out to countries around the world. On average, each 100g jar of oyster floss costs 150,000-180,000 VND. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 15](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/d909dd4b2de94e4199458bbfa1861cd5) |

Bavabi oyster floss is a very familiar brand of Quang Ninh. The standards of raw materials and oyster floss production process are always strictly followed to bring excellent quality products for health. |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 16](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/fe4efe157bca430bbd5e4e309f1e9847) |

| Ms. Pham Thi Thu Hien, Director of Bavabi Company shared with Nhan Dan Newspaper reporter: "As a pioneer enterprise in deep processing of oyster products, from 2014 to now, Bavabi has released a large amount of oyster floss to the market, making Van Don oyster floss a specialty product of Quang Ninh. It can be seen that the enterprise's participation in the production of OCOP products has created many competitive advantages, more professionalism and class". Along with constantly innovating technology and developing the market, Ms. Hien hopes that Van Don oyster floss will reach out to the world market even more". |

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 17](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/1/20/0c493076ad1945a1a026fdf08ab75fea) |

Oysters in general and Van Don oyster floss in particular are the pride of Quang Ninh people. |

People

source ![[Photo] Discover the production process of Van Don's specialty oyster floss photo 1](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_1-2290.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 2](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_2-586.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 3](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_1-7373.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 4](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_untitled-1-9682.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 5](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_2-4748.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 6](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_3-5118.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 7](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_4-8846.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 8](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_untitled-2-7295.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 9](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_5-221.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 10](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_untitled-3-8851.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 11](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_6-8317.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 12](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_7-4306.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 13](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_10-8007.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 14](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_9-5598.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 15](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_8-2989.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 16](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_untitled-1-2125.jpg.webp)

![[Photo] Discover the production process of Van Don's specialty oyster floss photo 17](https://image.nhandan.vn/w2000/Uploaded/2023/fdmzftmztpmf/2023_09_25/ndo_br_4-4735.jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/893f1141468a49e29fb42607a670b174)

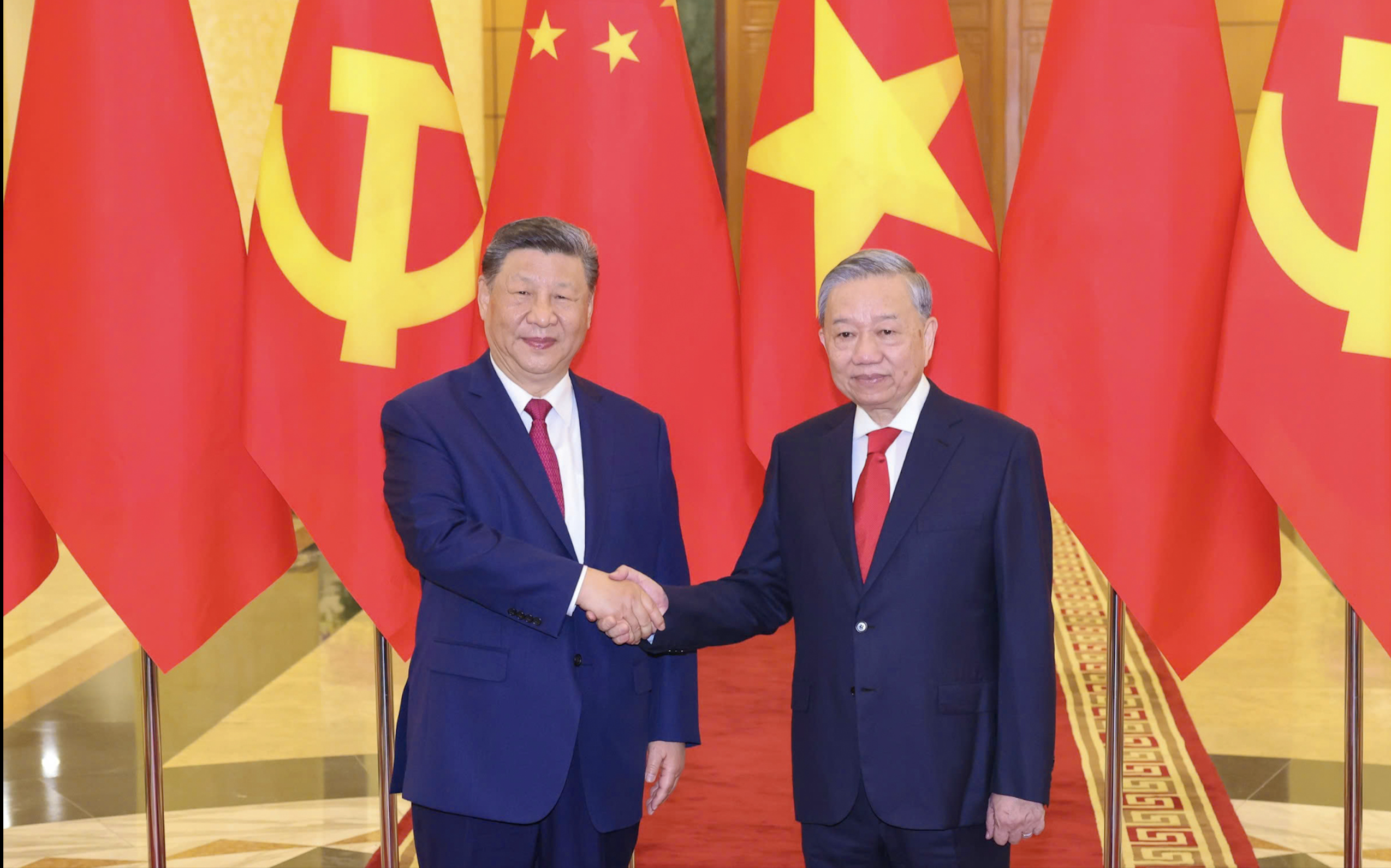

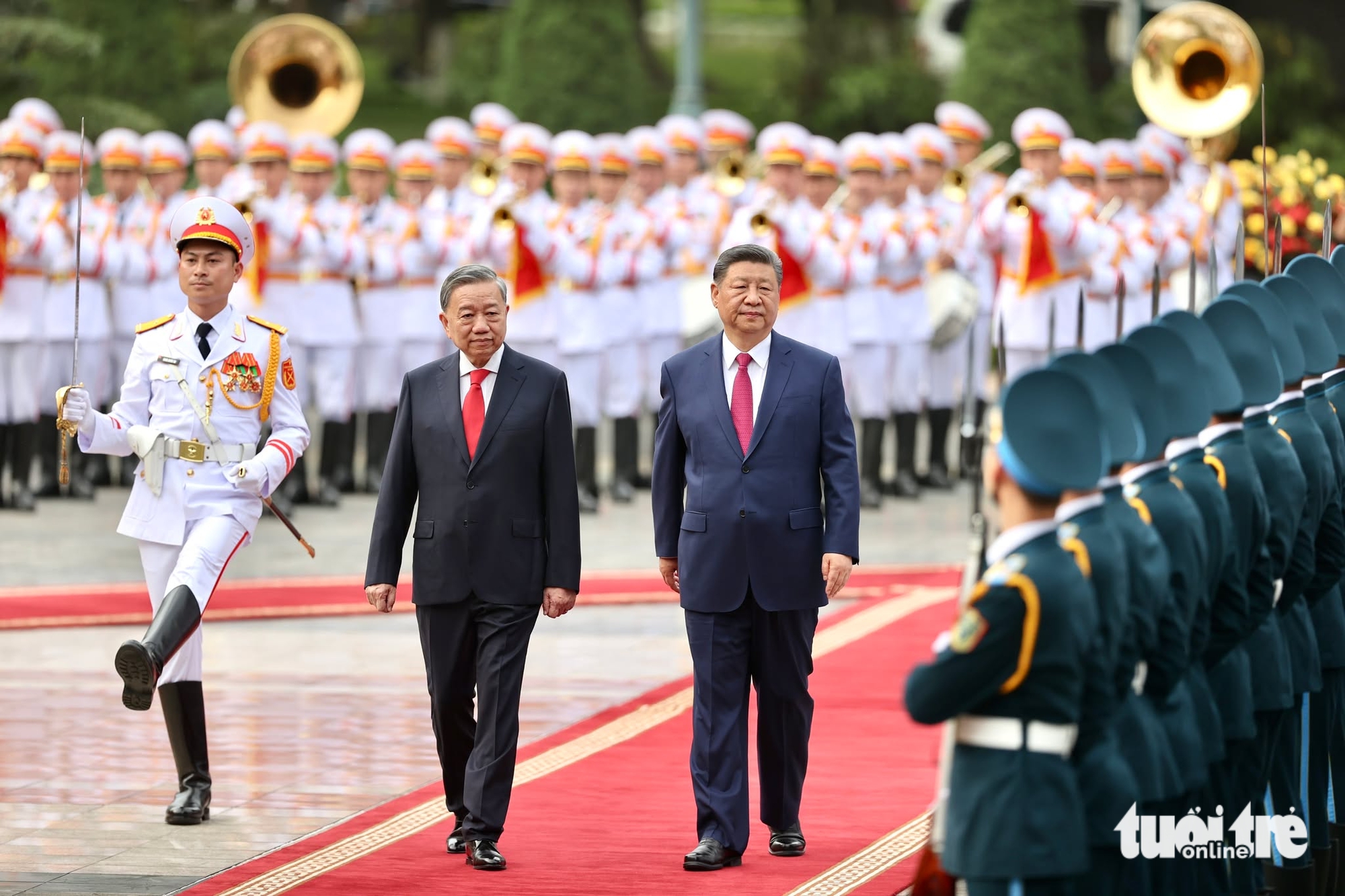

![[Photo] General Secretary To Lam holds talks with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/b3d07714dc6b4831833b48e0385d75c1)

![[Photo] National Assembly Chairman Tran Thanh Man meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/4e8fab54da744230b54598eff0070485)

![[Photo] Reception to welcome General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/9afa04a20e6441ca971f6f6b0c904ec2)

Comment (0)