Vietnam's textile industry is on the rise, production lines using self-lubricating solutions always help the machine operate smoothly to ensure productivity.

The textile industry is facing many challenges, from competitive pressure, increasing demands on product quality, to issues of maintenance and operation of machinery. In this context, the application of advanced technologies and solutions is the key for textile enterprises to improve productivity, reduce costs and maintain competitive advantage.

|

| The modern textile industry uses many technological machines to optimize the production process. Photo source: tapchitaichinh.vn |

One of the effective solutions that many Vietnamese textile and garment enterprises are interested in is using igus® xiros bearings. With outstanding advantages, xiros bearings not only help solve problems of wear, noise, lubrication, but also contribute to improving productivity and product quality.

Operational challenges of Vietnam's textile industry

Vietnam's textile and garment industry is facing many challenges in its production machinery, including:

Wear and damage: Machinery in the textile industry is often exposed to harsh environments, with lots of dust, chemicals and high humidity. This leads to wear and damage to components, especially bearings, causing downtime and high maintenance and replacement costs.

Noise and vibration: Textile machinery often generates loud noise and vibration during operation, affecting the health of workers and the working environment.

Lubrication and maintenance: Regular lubrication and maintenance of bearings in the textile industry is very costly and time consuming.

Hygiene and safety: In the textile industry, especially in the dyeing and printing stages, the use of chemicals can cause pollution and affect the health of workers.

Improving Productivity: Textile and garment businesses are always looking for ways to improve productivity and reduce production costs.

Why igus® solutions optimize performance and durability for textile machinery

igus® xiros bearings are an optimal solution for the Vietnamese textile industry, helping to effectively solve the above challenges. With outstanding advantages, xiros bearings bring many benefits to businesses:

The textile industry requires equipment to operate continuously at high speeds, which leads to rapid wear and significant maintenance costs. To address these challenges, igus® offers innovative solutions such as iglidur®, igubal® and xiros®, which enhance the performance and durability of textile machinery.

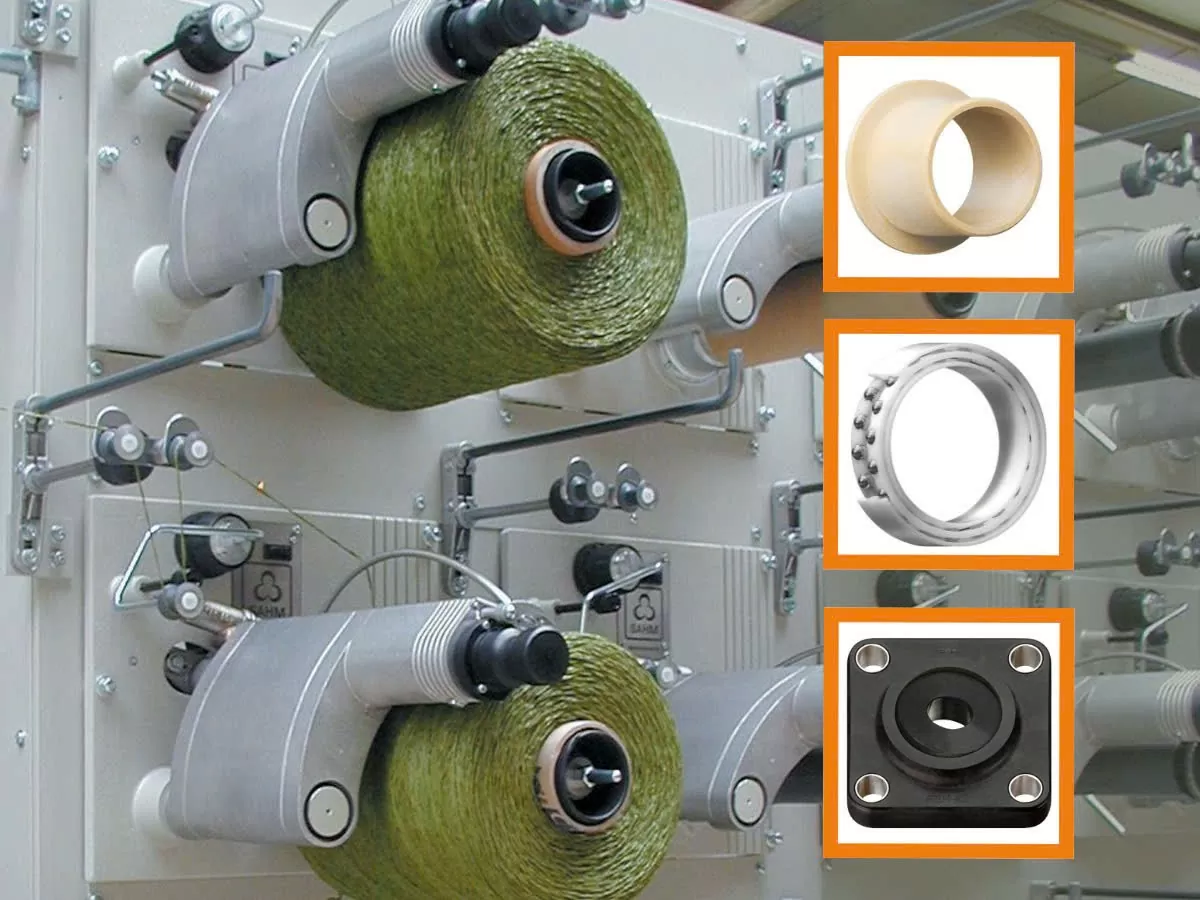

|

| Bearing solutions: bushings, ball bearings, housings... in completed projects of igus. Source: igus GmbH |

iglidur® plain bearings: Made from high-performance polymers, iglidur® plain bearings require no lubrication, which helps to minimise dirt adhesion to the fabric and ensures a clean production environment. They are wear-resistant and can withstand high speeds, making them ideal for applications such as spindles and guide rollers in textile machines.

igubal® ball bearings: With their self-aligning and vibration-absorbing properties, igubal® ball bearings reduce noise and increase the life of machine components. They are suitable for tensioning systems and drive rods where high precision and reliability are required.

xiros® plastic bearings: Lightweight, corrosion-resistant and maintenance-free, xiros® bearings perform well in the wet and chemical environments commonly encountered in textile dyeing and finishing. Their heat and chemical resistance ensure consistent performance and minimize downtime.

Application of igus® products in your machinery

Many textile companies around the world have trusted and applied igus® iglidur®, igubal® and xiros® solutions in their production processes, helping to improve performance, reduce maintenance costs and extend equipment life. Here are some typical applications you can use to optimize your production line:

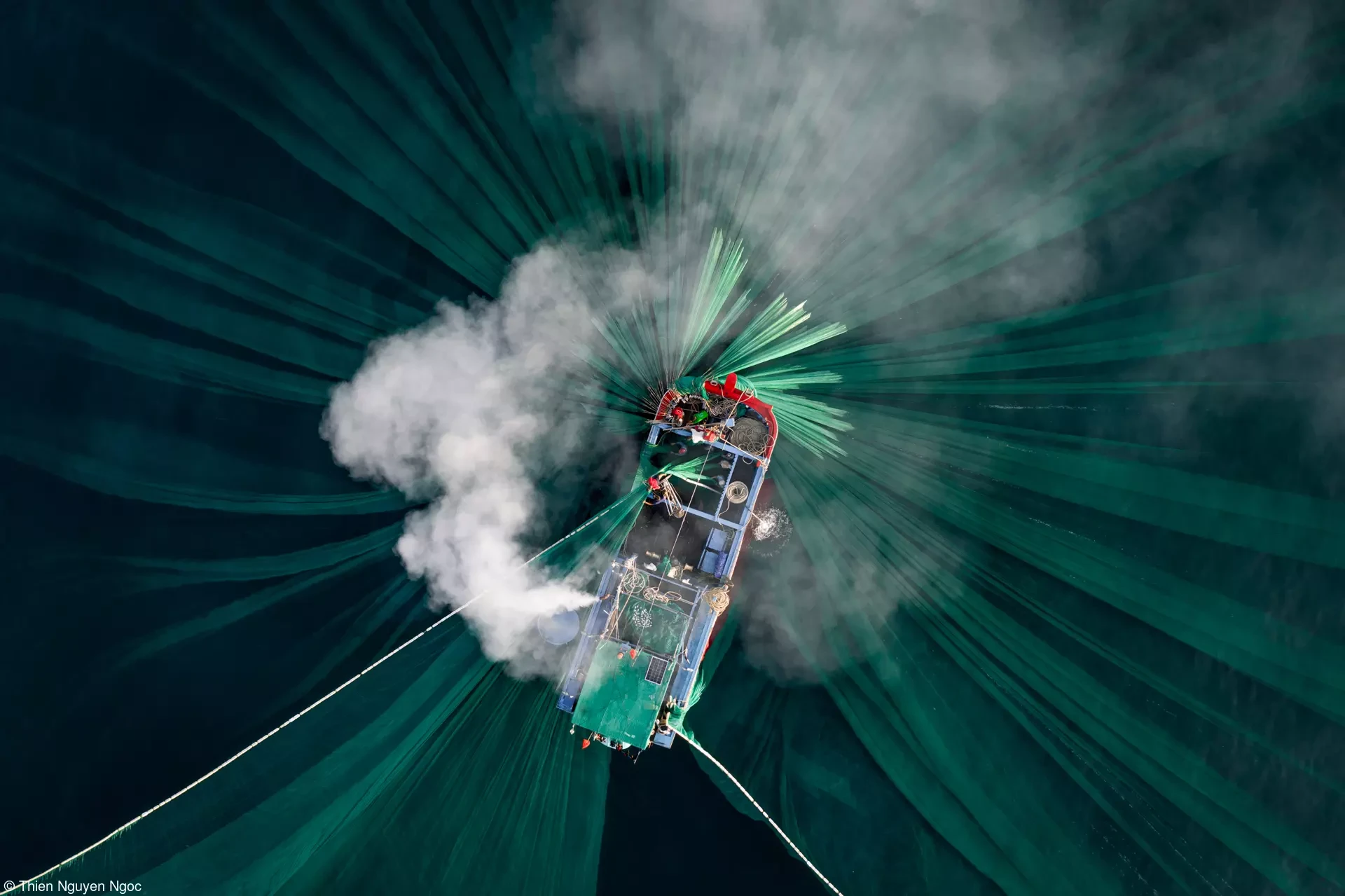

|

| Application of high-performance plastics in textile production lines. Source: igus Gmb-H |

Circular knitting machines: iglidur® bearings on the rollers and guide shafts reduce friction and eliminate the need for lubrication, thereby increasing weaving speeds and reducing maintenance times.

Textile dyeing and finishing lines: With their chemical resistance due to high-performance plastics, igus® products are perfectly suited for chemical environments where corrosion resistance is an important factor. This ensures stable operation without interruption due to breakdowns.

Automatic tensioning systems: igus® offers a wide range of product profiles in multiple materials to meet customer needs, with lines specifically designed to reduce vibrations and noise during operation, improve system precision and durability, and minimize downtime for maintenance.

igus® solutions are always an optimal solution for the Vietnamese textile industry, helping to effectively solve challenges related to wear, noise, lubrication, hygiene and productivity. With outstanding advantages, bearing products: bushings, pillow blocks, ball bearings, bearings, etc. made of high-performance plastic not only help textile enterprises reduce production costs, but also contribute to improving product quality and maintaining competitive advantages in the market.

| Hopefully this article has provided you with useful information about igus® solutions and their applications in the Vietnamese textile industry. If you have any questions, please contact igus® at +8428 3636 4189 or refer to the link: https://www.igus.vn/info/industries-textile. |

Source: https://congthuong.vn/chuyen-dong-khong-chat-boi-tron-giai-phap-toi-uu-cho-nganh-det-may-374858.html

Comment (0)