Thanks to the application of machinery in production, the forged products of Mr. Bui Van Khang (Nhi Thanh commune, Thu Thua district) have increased in quality and quantity.

Mr. Bui Van Khang's forge has existed for nearly 100 years, passed down from father to son, he is the third generation. Mr. Khang said that he started this profession at the age of 10, and now has nearly 40 years of experience. He does not know who started this profession, and the elders do not know either, but whoever does this profession is grateful to their ancestors - the people who started it so that they have "food to eat and clothes to wear".

The land reclamation work of our ancestors mostly used human power. The main labor tools were flats, hoes, sickles, shovels, etc. It can be seen that the blacksmiths were formed from our ancestors' need to conquer nature. When the land reclamation work in Dong Thap Muoi was promoted, the blacksmiths prospered. Mr. Khang said: "About 30-40 years ago, the blacksmiths worked day and night. Wherever you go in this village, you can hear the sound of hammers."

Mr. Khang lives near Cau Bong (Hamlet 4), people build houses close together, forming a crowded hamlet next to Cay Gao canal. In the past, there was no electricity or fans, blacksmiths often got up early and rested at noon to avoid the heat. Raw materials and products were transported by river because at that time road traffic was very limited. Now the road to Mr. Khang's house has been concreted, making trading faster and more convenient.

His parents gave birth to 13 children, 7 of whom followed the profession. When his daughter got married, his father married her and passed on the profession, thanks to which the family's economy gradually stabilized. Nowadays, farmers apply mechanization in production, so they rarely use agricultural tools. That is one of the reasons why many blacksmiths specializing in sickles, hoes, hammers, and spades, etc. have few customers and are gradually closing down. Currently, in the whole Nhi Thanh commune, there are only about 25 households following the profession, mainly in hamlets: 3, 4, and 5.

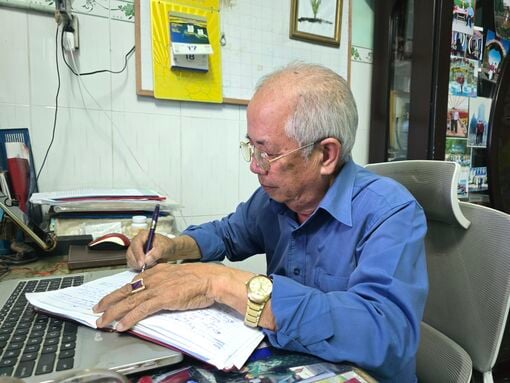

Khang's forge makes planers - a very common kitchen tool. According to Khang, this product is still eliminated by the market if the craftsman is careless, chasing profits and forgetting about quality. Low-quality products make it difficult to compete with industrial products and increase prices according to steel prices. "A planer looks small but has to go through nearly 20 stages to get the finished product. There are steps that require technique and attention, if you are careless, the product is defective" - Khang said. Thanks to the meticulousness of each step, the products of Ut Be forge (Khang's common name) are present in all provinces and cities of the Southwest. During the days before Tet, he has to work overtime continuously to have enough goods to deliver.

The blacksmith's job is very hard but they are still passionate even though this profession is gradually fading away.

According to Mr. Khang, blacksmithing requires good health and is therefore only suitable for men. For blacksmiths, cuts and bleeding are common; in addition, they often suffer from dry eyes due to exposure to high temperatures, and bone and joint diseases due to sitting for long periods and heavy labor. Despite the hardship, Mr. Khang still loves his job very much. For him, blacksmithing is a noble profession, thanks to which his parents support the whole family. Blacksmithing is also the pride of his family in particular and the locality in general.

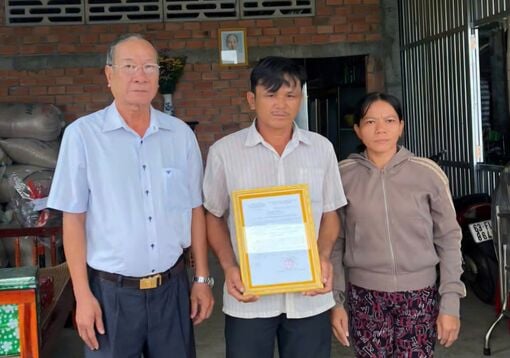

Mr. Khang added that currently, thanks to the application of modern machinery, the quality and quantity of products have both increased, and the workers have less hardship. During the working process, he constantly researches and improves to make the products better and better, meeting the increasingly high demands of customers. In 2024, he was awarded the Certificate of Technical Innovation by the Provincial Farmers' Association with the initiative to Improve the features of forged product stamping machines.

Thanks to decades of intermediary work, his product output is stable. Every day, he produces hundreds of products, creating jobs for a number of local workers. Currently, his son knows the trade and wants to follow in his father's footsteps. Mr. Khang himself has been recognized as a skilled worker by the Provincial People's Committee.

We asked the blacksmiths how they felt when they saw their traditional profession gradually disappear. They smiled, a little regretful but not too sad because they understood the ups and downs of life, nothing lasts forever. For them, as long as the hammer handle is floating, they are enthusiastic and passionate, and when times change, they are flexible and adaptable. The sound of hammering is gradually fading away but their love for the profession is still burning because those images and sounds still linger in the hearts of the children of the blacksmith village./ .

C.Thanh

Source: https://baolongan.vn/ve-tham-lai-xom-lo-ren-a193209.html

![[Photo] Visitors are excited about the interactive exhibition organized by Nhan Dan Newspaper to celebrate the 50th anniversary of the Liberation of the South and National Reunification Day.](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/23/e00e0e8c0ba04820add26d1af056b697)

![[Photo] General Secretary To Lam receives CEO of Rosen Partners Group (USA)](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/23/2537171fceee43b19a8eec00d22823ff)

![[Photo] Discover Vietnam's leading aircraft maintenance workshop at Noi Bai airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/23/b12dde66f5374591b818f103e052cce5)

![[Photo] Nhan Dan Newspaper introduces special information session and interactive exhibition to celebrate the 50th anniversary of the Liberation of the South and National Reunification Day](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/23/7c6ef4280e1545a69b460246888eea10)

Comment (0)