Regular from equipment to professional activities

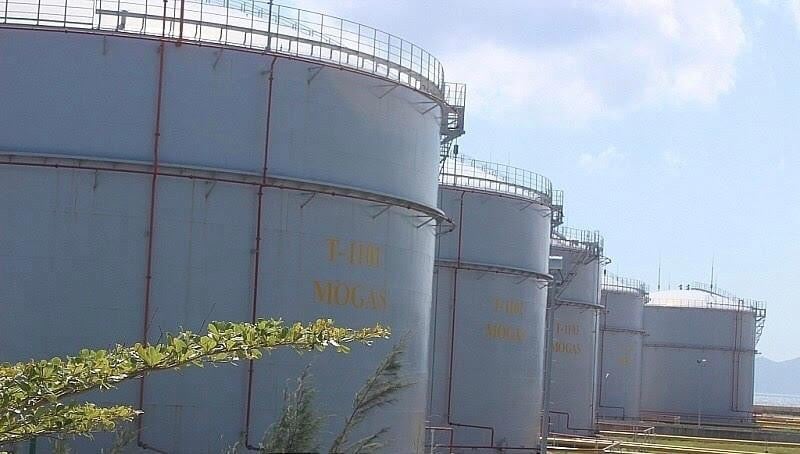

The warehouse was built in the 1990s, with the task of storing, preserving, and distributing gasoline to units of the 1st Corps performing regular, combat readiness, and emergency tasks. The warehouse is arranged into 5 sub-areas, including: Regular and combat readiness distribution area; oil and grease warehouse; petroleum equipment warehouse; vertical tank area (cluster of 4 vertical tanks); underground tank system area (cluster of 4 underground tanks), fire prevention and fighting system. In recent years, despite many difficulties, the Petroleum Warehouse has always received attention from the Corps Command and the Logistics Department in terms of investment in repair, maintenance, and upgrading of the tank system, pipelines, warehouses, fire prevention and fighting equipment, internal roads, etc., so it can receive and distribute fuel in all conditions.

In particular, in 2022, the Corps Command invested over 200 million VND in the Warehouse, combined with the efforts of the troops to repair, upgrade, and renovate the tank system, warehouse, equipment, fire-fighting tools, and install a new gasoline and oil distribution system... contributing to improving the overall quality of the Warehouse. With current equipment, the Warehouse can receive 5 tankers at the same time or distribute to 7 tankers at the same time.

As one of the warehouses in the campaign-level logistics warehouse system, the Warehouse is always directed and maintained in a regular and disciplined manner by the Corps Logistics Department and the Petroleum Department. The Warehouse area always ensures adequate floor plans, technological diagrams, internal rules and regulations on warehouse operations; procedures for receiving, distributing, operating pumping stations, preserving and maintaining petroleum equipment and weapons; the system of signs, slogans, etc. are designed according to prescribed models and arranged scientifically, systematically and aesthetically. Every year, the signboard system is repaired and upgraded to meet regular requirements.

Plans for fire prevention, fighting, and on-site combat to protect petroleum depots are regularly inspected, adjusted, and supplemented by the Petroleum Department to be closer to reality. The warehouse system and fuel tanks are numbered according to the regulations of the General Staff. In addition, warehouse operations are also maintained in a disciplined manner according to unified regulations, such as: Distribution schedule on Tuesdays and Thursdays every week; storage and maintenance on Mondays, Wednesdays, and Fridays every week. Due to the maintenance of a regular routine, operations at the warehouse are always guaranteed to be on schedule.

Apply safety measures

The activities of receiving, storing and distributing gasoline are prone to safety incidents, therefore, the Petroleum Department pays special attention to warehouse safety. Under the direction of the Petroleum Department, warehouse activities must strictly comply with safety regulations. Before receiving and distributing fuel, warehouse staff must report to the General Logistics Warehouse Commander to arrange forces to be ready to handle fire and explosion situations, ensuring the safety of people, vehicles and materials. When receiving and distributing fuel, staff must strictly comply with professional principles to ensure safety.

For equipment, tools, water tanks, sand pits, etc. serving fire prevention and fighting, they are always maintained in sufficient quantity and good quality. Equipment, tools and fire hydrants are arranged around the vertical and submerged tanks. On the roof of each vertical tank, an automatic water sprinkler system is installed to cool the tanks when the outside temperature is too high or to be used in case of fire or explosion. In the Warehouse area, there are 2 large capacity fire pump houses with many hydrants and equipped with 1 mobile water pump, 3 rotating nozzles with vortex jets to extinguish the fire in 3 directions and can penetrate metal doors or 10cm thick walls when necessary, ensuring the fastest fire extinguishing.

The entire warehouse area is surrounded by a wall; a protective lighting system is installed and there is a sufficient lightning protection system to ensure good quality. Along with that, the Warehouse area is arranged with 2 24/24 hour watchtowers, the communication system ensures smooth operation, and can notify the fastest alarm signal when necessary. The area around the Warehouse is regularly cleared to prevent fire from spreading and falling trees causing unsafe conditions. The valve and fuel pipeline systems are regularly checked by staff periodically and before fuel is exported or imported. In addition, according to the plan, each month, Warehouse officers and employees organize training and practice fire prevention, fire fighting, and on-site combat to protect the warehouse twice.

During the year, the Petroleum Department organized in-service training sessions on professional skills and the use of equipment for the Warehouse staff, especially new equipment such as the DC-100 field petroleum storage set... The Warehouse Commander maintained coordination and cooperation with friendly units and local fire prevention and fighting police to participate in practicing fire prevention and fighting plans and handling of petroleum warehouse fires. By implementing synchronous measures, the Warehouse always ensures the safety of people, vehicles and fuel in the warehouse.

Savings in operations

Identifying thrift practice, anti-corruption and waste as the core content in the management and use of petroleum of the 1st Corps, the Petroleum Department regularly propagates and educates cadres, employees in the agency and employees directly working at the Warehouse on thrift awareness in professional stages. This is considered one of the important criteria to evaluate the quality of cadres and party members. Along with that, the Department regularly promotes the emulation movement "Management and use of petroleum safely, economically and effectively", integrating it with the contents of the emulation movement "The Military Logistics Sector follows Uncle Ho's teachings". The Petroleum Department proactively researches and applies many measures to practice thrift in all professional stages to reduce the loss rate below the allowable level.

Specifically, implement full and compact storage in tanks to limit evaporation; install a pressure-regulating respirator valve system to prevent evaporation; install an automatic water spray cooling system when the outdoor temperature increases. When organizing the reception and distribution of limited fuel at times when the outdoor temperature increases to avoid fuel evaporation beyond the allowable level and ensure environmental hygiene. Regularly invest in purchasing new, maintaining, repairing, and upgrading pipeline systems and filling valves to avoid fuel leakage. Encourage petroleum officers and employees to actively research and apply technical innovations and information technology in management work... Due to the synchronous implementation of saving measures in professional activities, the Petroleum Depot does not allow loss or deficit of petroleum beyond the allowable level, always meeting requirements and tasks.

Despite many difficulties, with the efforts of the Petroleum Department and staff, the Petroleum Depot (Logistics Department of the 1st Corps) always meets the requirements of regularity, ensures safety, completes tasks well, and is highly appreciated by superiors.

NGOC HOI

Source

Comment (0)