Quang Nam Refusing a job at a bank, Tran Thi Yen returned to her hometown and, with her father, preserved the traditional Ma Chau silk weaving profession that was in danger of disappearing.

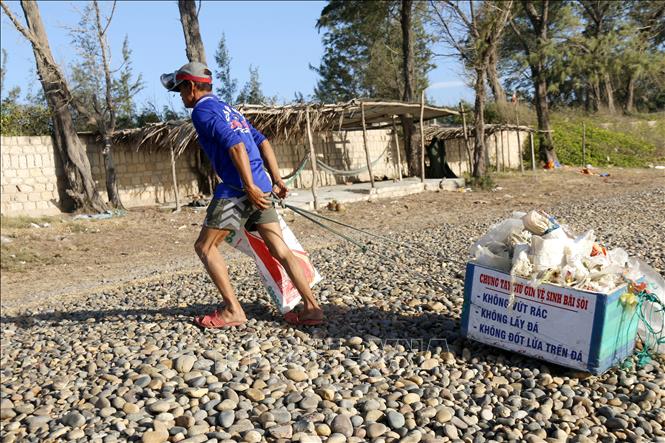

In early May, in a 3,000-square-meter silk weaving workshop in the center of Nam Phuoc town, Duy Xuyen district, 10 workers were diligently working at the loom. Through the hands of the artisans, natural silk became soft, eye-catching pieces of silk. "Ma Chau silk is durable, light, heat-resistant, and mold-resistant," said Tran Thi Yen (31 years old), manager of the weaving workshop.

Nine years ago, after graduating from the Business Administration major at the University of Economics in Da Nang, Yen was hired by a bank in Tam Ky City. However, the night before she started work, a conversation with her father, Mr. Tran Huu Phuong - Chairman of the Ma Chau Silk Cooperative, completely changed her direction.

Ma Chau village used to have more than 300 households raising silk with 4,000 silk weaving frames, but now only Mr. Phuong remains to maintain the profession. The market has seen the appearance of many types of cheap industrial silk fabrics with diverse designs, making it impossible for the cooperative to find a market for them. They only sell raw products to other units, resulting in continuous losses. Yen decided to stay in her hometown and work with her father to restore the craft village.

"People start a business from zero, but I started with a negative number because my father's cooperative was in debt of hundreds of millions of dong," she said, adding that she had asked her father to mortgage their house and borrow money from the bank to help her find the Ma Chau brand again.

Tran Thi Yen is checking the fabrics being woven. Photo: Dac Thanh

In the early days of her career, Yen brought 100% natural silk fabrics to many shops in Hoi An City to sell, but only received head shakes. They said the products were good and beautiful, but three times more expensive than the import price of the items being sold. Some even said that these were fake goods because "there was no Ma Chau silk left".

The products were not selling and there was no financial source to pay the workers, so Yen asked her father to increase the bank loan limit to have money to cover the expenses. She realized that she had to make products to meet market demand. In addition to silk fabrics made from silk fibers, Yen began to try making them from linen and bamboo fibers to reduce costs.

She continued to bring the fabric to major cities and fairs; sent samples to stores; and introduced Ma Chau silk on social media. Yen also tried to connect with some young designers, inviting them to use Ma Chau silk for fashion products.

After a while, customers saw that the quality was good, so more fabric was sold, and she started to earn income. From mid-range products, customers looked for higher-end items. "This is a sign for development," Yen said, adding that since then, in addition to traditional wooden looms, she has invested in many modern machines to increase product quality.

In just four years from 2018 to 2022, Yen used more than 10 billion VND from profits and loans from banks and relatives to invest in many modern machines. That is digital programming technology to weave patterns on natural silk fabric along with a system of rolling and drying machines to shape and dye with herbs.

Yen checks the stage of feeding silk thread into the loom. Photo: Dac Thanh

Currently, the textile factory supplies the market with 3,000 meters of fabric each month, with prices ranging from 130,000 VND to 1.8 million VND per meter. The products are ordered by famous fashion brands; many businesses place orders according to their own designs, which are also met by the company. The popular products help Yen achieve a total annual revenue of more than 2 billion VND, with a profit of about 500 million VND after deducting expenses.

In 2018, the Ma Chau silk identification logo was born. Also in this year, the Korean KIPO and KIPA organizations selected Ma Chau as the only brand in Vietnam to be protected by global trademarks. In 2021, Ma Chau silk scarves were recognized as 4-star OCOP products of Quang Nam.

"Although I chose a busy job, I am happy to be the boss in my own hometown, to continue my father's profession, to create regular jobs for 10 people with an income of 4-7 million VND per month," Yen said. She said that in the future, she will develop the craft village into a tourist attraction, welcoming tourists, forming a community tourism area with many households growing mulberry, raising silkworms, and weaving.

Many products are displayed by Yen at the company. Photo: Dac Thanh

Chairwoman of the Duy Xuyen District Women's Union Tran Thi Minh Yen highly appreciated Tran Thi Yen's dedication to restoring the Ma Chau silk weaving village. "Yen has a creative mindset, combined with her highly skilled father, not only preserving the craft village but also developing the Ma Chau silk brand with products that meet consumer demands," she said.

Ma Chau silk weaving has existed since the 16th century. Legend has it that a woman named Ma Chau from Kinh Bac migrated to the south. On the way, she stopped at the land along the vast alluvial Thu Bon River, where the Cham people grew mulberry trees and raised silkworms to make silk for weaving brocade. She taught the local people the art of weaving, using the loom she carried on her shoulder when she moved south.

Grateful to her, the people named the village Ma Chau - close to her name to avoid taboo. Ma Chau silk later became famous in Dang Trong when ships entered Hoi An city for trade, Hoi An port and Do To wharf were important nodes in the maritime silk road at that time. Ma Chau silk was also supplied to the nobility and mandarins in the royal court.

Source link

Comment (0)