The solemn flag-raising ceremony opened the TPM Day program at Hai Duong factory.

Mr. Wirath Buayam - Representative of the Company's Board of Directors gave an opening speech at the conference, encouraging the factory's staff to continue implementing TPM and emphasizing: "TPM is a daily task, so I hope that all factory staff will work together and help each other to complete the work. The factory's TPM goal in 2024 and early 2025 is to evaluate AM through step 5 and implement step 6. So that we are eligible to participate in the TPM Consistency Award competition".

Mr. Wirath Buayam - Representative of the company's board of directors spoke at the program.

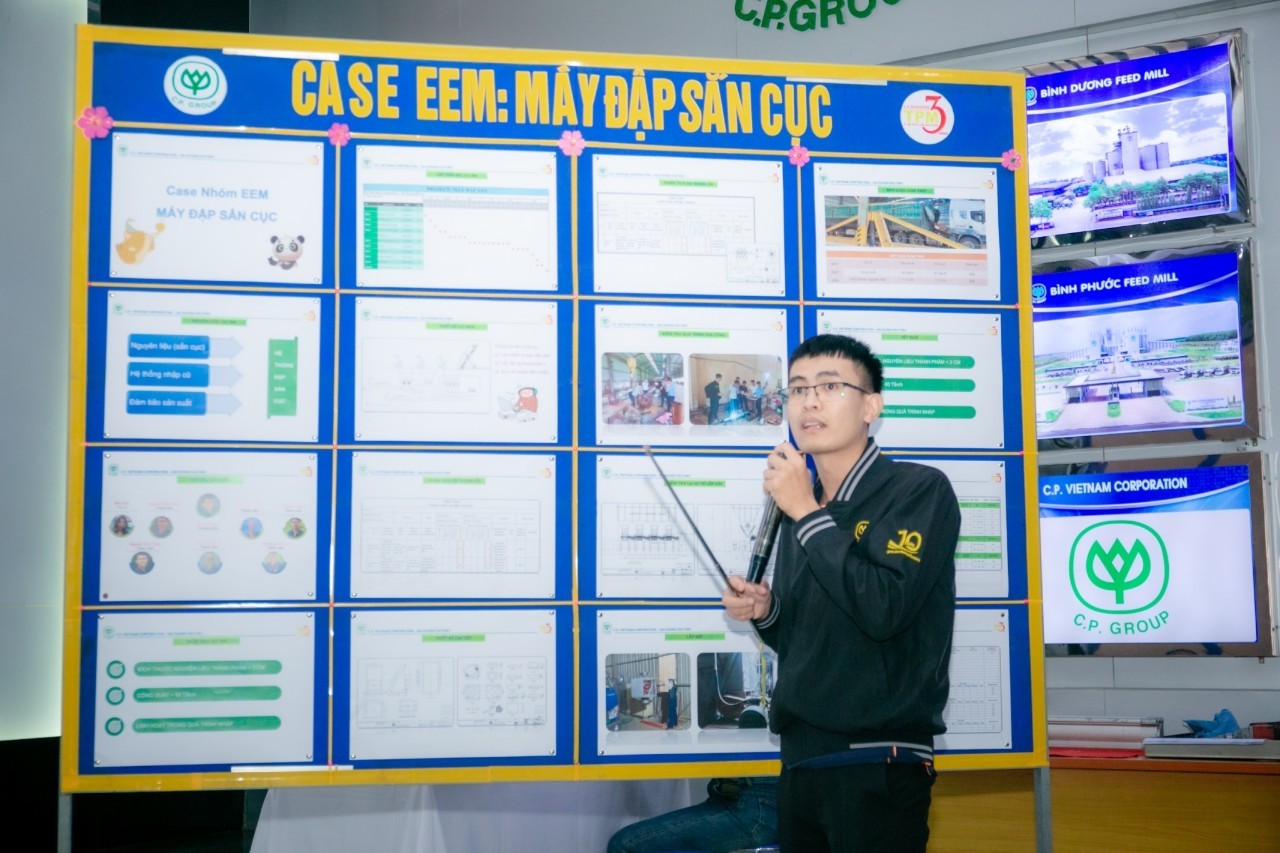

Mr. Phung Anh Tuan - Representative of TPM Center factory reported on TPM activities in the past 10 months of 2024 and the heads of the columns reported on TPM knowledge, introduced activities, progress and achieved results.

TPM Center representative of the factory reported TPM activities in the past 10 months.

TPM Center representative of the factory reported TPM activities in the past 10 months. TPM is a management method first applied in Japan, then popularized and widely applied in industrial manufacturing industries around the world . The concept and method of TPM were first introduced by the Japan Institute of Plant Maintenance (JIPM) in 1971. Starting from the 1980s, TPM began to be widely popularized outside of Japan. TPM is a combination of PM and part of TQM (Total Quality Management System). To be effective, TPM needs to be widely implemented throughout the organization. Involving all departments and everyone involved. TPM implementation aims to maximize equipment performance, improve productivity with a maintenance system implemented throughout the life cycle of the equipment, and at the same time improve employee awareness and satisfaction with work. With TPM, everyone unites and agrees with each other to improve equipment performance in the most effective way. The idea that it is my responsibility to operate the equipment, and your responsibility to repair the equipment, has been replaced by “You and I are both responsible for our equipment, our plant, our future.”

TPM Day Overview

The Board of Directors of CP Group in general and TăGS Hai Duong factory in particular, have decided to apply the TPM system to the production and business sector to improve productivity and quality to help the company grow and develop sustainably. CP Hai Duong factory has implemented TPM activities to expand the factory since December 2018. In 2021, the factory passed 2 assessments and won the TPM Excellence Awards. The next goal of the factory is to conquer the TPM Consistency Award in 2025. 2024 is considered the foundation year for the factory to develop TPM to meet the TPM Consistency award criteria. The TPM Day program organized by the factory is a stepping stone to get closer to the target award. Within the framework of the program, the TPM committee also summarized the Kaizen (improvement) activities to turn difficult tasks into easy tasks, turn easy tasks into easier tasks, and develop kaizen work into a working culture for employees in the factory. The management board also awarded the best kaizen prizes to groups in 2023, 2024 and 5 outstanding individuals based on the results of the number of individuals with many hang tags, OPL, Kaizen and training courses.

Photo: The Board of Directors awarded prizes in the program Source: https://www.cp.com.vn/truyen-thong/tin-tuc-su-kien/ngay-hoi-tpm-day-tai-cp-viet-nam--chi-nhanh-nha-may-tai-hai-duong

Photo: The Board of Directors awarded prizes in the program Source: https://www.cp.com.vn/truyen-thong/tin-tuc-su-kien/ngay-hoi-tpm-day-tai-cp-viet-nam--chi-nhanh-nha-may-tai-hai-duong

![[Photo] Prime Minister Pham Minh Chinh chairs meeting on science and technology development](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/17/ae80dd74c384439789b12013c738a045)

![[Photo] More than 17,000 candidates participate in the 2025 SPT Competency Assessment Test of Hanoi National University of Education](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/17/e538d9a1636c407cbb211b314e6303fd)

![[Photo] Readers line up to visit the photo exhibition and receive a special publication commemorating the 135th birthday of President Ho Chi Minh at Nhan Dan Newspaper](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/17/85b3197fc6bd43e6a9ee4db15101005b)

![[Photo] Nearly 3,000 students moved by stories about soldiers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/17/21da57c8241e42438b423eaa37215e0e)

Comment (0)