Ms. Yen starts her day with two busy workers producing and drying pho noodles in the sun to store for the winter. “When the weather is hot, my facility produces as much pho as possible to ensure the quality of the product is delicious. During the rainy season, this is more difficult because there is no direct sunlight, so we have to use a high-intensity drying oven, which consumes a lot of electricity,” Ms. Yen explained.

Ms. Yen shared about the opportunity to join this profession, that is, after graduating from nursing school, she worked at Hoi An General Hospital. After 3 years, she had to quit her job because of many difficulties that arose after giving birth to her first child. In 2017, she decided to continue her husband's family's traditional profession of making dried pho.

“When I was a nurse at the hospital, I had a hard time, but I felt happy when I saw patients recovering day by day... After I quit my job at the hospital, I was quite sad, but as a woman, I wanted to spend most of my time taking care of my family.

On the other hand, I found that the locality has a fairly abundant and delicious source of rice, but when sold to the market, the price is low. From there, I decided to choose my family's traditional pho making profession to start a business. I want to make quality pho noodles to provide to consumers, thereby increasing the value of rice grains produced by local people" - Ms. Yen said.

Yen and her husband invested more than 200 million VND to buy machinery, raw materials and started to restore the pho production business, calling the facility Mrs. Yen's Dry Pho - Vermicelli.

After the noodles are dried, she carefully packages and preserves them. After more than 8 years in this profession, she supplies tons of dried noodles to the market every month.

“Producing pho seems easy, but to make quality dry pho noodles, it goes through many stages. The most difficult step is choosing the rice and processing it before putting it into the machine until the finished product to make the pho noodles both chewy and soft,” Ms. Yen shared.

Each kilo of dried pho costs 40,000 VND. Her pho consumption markets are traditional markets, large and small supermarkets in Quang Nam province and Da Nang city. Her revenue is about 100 million VND/month, after deducting labor and raw material costs, the remaining profit is about 30 million VND/month.

To have a source of Q5 rice for pho production, Ms. Yen also cooperates with dozens of local farmers to produce this rice variety and purchase it annually, helping farmers have a stable source of consumption. Her pho production facility also creates regular jobs for 3 local workers with an income of 200,000 VND/day.

Currently, Ms. Yen has completed the application to participate in the province's Creative Startup Competition held in May 2024. Next year, she plans to expand her production facility and invest in more machinery to produce in large quantities to supply to customers.

[VIDEO] - Ms. Pham Thi Hong Yen shares her startup story:

Mr. Doan Cong Dao - Vice Chairman of Dien Phuong Ward People's Committee said that currently, there are 3 products in the locality that meet OCOP standards. Ms. Yen's dry pho product in Triem Dong 1 block is very promising and the family has applied to register for the province's startup idea competition.

In recent times, the locality has always researched and guided pho production facilities, carpentry, bronze casting... to complete registration procedures and encouraged local development to bring more and more products to the market. "Mrs. Yen's pho production facility not only enriches her family but also creates jobs for many local workers, which is also a good thing," said Mr. Dao.

Source

![[Photo] Tourists line up to receive special information publications from Nhan Dan Newspaper](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/24/3ac2c0b871244512821f155998ffdd60)

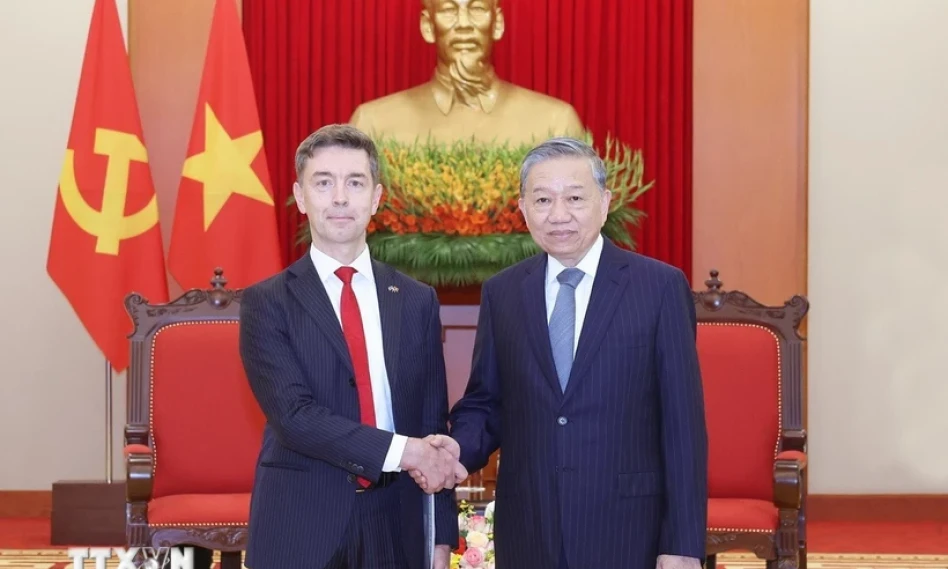

![[Photo] General Secretary To Lam receives Philippine Ambassador Meynardo Los Banos Montealegre](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/24/6b6762efa7ce44f0b61126a695adf05d)

![[Photo] President Luong Cuong holds talks with Lao General Secretary and President Thongloun Sisoulith](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/24/98d46f3dbee14bb6bd15dbe2ad5a7338)

![[Photo] Prime Minister Pham Minh Chinh works with the Academy of Posts and Telecommunications Technology](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/24/83f86984b516422fb64bb4640c4f85eb)

Comment (0)