Vietnam's mechanical engineering industry is facing many challenges, from technology to management and competition in the international market.

Mechanical products account for only 7% of domestic market share.

According to Department of Industry (Ministry of Industry and Trade), with products such as molds, mechanical components, horses and technical rubber,... domestic mechanics have undertaken with good capacity.

Specifically, domestically produced metal components have met 85-90% of the demand for motorbike production; about 15-40% of the demand for components for automobile production (depending on vehicle type), about 20% for the production of synchronous equipment and 40-60% for the production of agricultural machinery, power machinery and 40% for construction machinery. The supply of metal components for high-tech industries currently meets about 10% of the demand.

According to the Vietnam Association of Mechanical Enterprises (VAMI), although there have been many advances in the production of mechanical products, Supporting industry; many products have connected and reached out to foreign countries, but in general, the products of the majority of domestic enterprises still have low quality and accuracy, high production costs, so they lack competitiveness.

“ The whole country has about 3,100 enterprises. mechanical industry manufacturing with 53,000 production facilities, but domestically produced mechanical products currently only account for about 7% of the market share. While the market share is very large, up to hundreds of billions of USD, but do businesses have enough competitiveness and ability to capture market share in it ? - VAMI stated the current situation.

In fact, there are some enterprises that have the conditions to invest in modern machinery and equipment, capable of manufacturing high-quality products for export and to replace imported goods, but the number of these enterprises is still too small and they are also facing many difficulties to survive and develop sustainably. Accordingly, each year, our country has to spend tens of billions of USD to import machinery and equipment to build projects and develop domestic industries, while the Vietnamese mechanical engineering industry can only meet a small part.

The reason for the above situation is that all levels and sectors have not yet fully recognized the position and necessary role in building and developing the mechanical industry; the State's mechanisms and policies have not been sufficient to create conditions to encourage and develop the mechanical industry. While the world is moving towards the 4.0 industrial era, the production level of the Vietnamese mechanical industry is still in the early stages of 3.0 due to the lack of resources to invest in new technology, weak technical infrastructure and skills.

In addition, in reality, the quality of industrial products supporting the mechanical industry of some domestic enterprises is still low, and the production cost is high, so it lacks competitiveness. At the same time, there is a lack of large, international mechanical enterprises that play a leading role.

Developing downstream industry, increasing localization

According to economic experts, in order for the Vietnamese mechanical industry to be competitive with FDI enterprises, management agencies need to have policies and mechanisms to encourage business development and require economic projects to prioritize the use of domestic goods.

Ms. Truong Thi Chi Binh - General Secretary of the Vietnam Association of Supporting Industries (VASI) said that if the domestic mechanical industry wants to develop, it must have a market, but to do this, the Government needs to have its own mechanism for the industry. Specifically, there must be a clear policy for domestically produced mechanical products in the direction that if any equipment can be produced domestically, it will be resolutely not allowed to be imported.

Talking to the Industry and Trade Newspaper, Mr. Do Hoai Nam - Chairman of the Board of Directors of Hanoi Mechanical Company expressed that the most important thing for mechanical enterprises is the market. The Ministry of Industry and Trade needs to shape how domestic enterprises can respond and divide the market to have the opportunity to supply products to the domestic market. Then, boldly invest in new equipment and technology to reduce production costs and compete to participate in the supply chain.

Adding his point of view, Mr. Do Phuoc Tong - Chairman of the Ho Chi Minh City Association of Mechanical and Electrical Enterprises (HAMEE), mechanical enterprises need to fully understand the needs of the global market, clearly understand the needs of customers. How many, what kind of products, what added service value, what improvements are expected. From there, enterprises can see their position as well as what limitations still exist that need to be overcome to be able to meet the requirements of the global supply chain such as what processes need to be set up, what certificates need to be provided, what skills need to be developed.

“Based on that, mechanical enterprises themselves need to proactively restructure production, find suitable directions for the enterprise, actively innovate, improve corporate governance efficiency, find ways to reduce input costs, improve productivity and quality; expand the market, proactively participate in the global value chain, link the production processes of large corporations in the world to expand export markets and take advantage of new technologies. With weak resources, it is difficult for us to compete with large companies and multinational corporations, so we must find solutions to link and cooperate with these enterprises for development, ” said Mr. Do Phuoc Tong.

On the side of the Ministry of Industry and Trade, Mr. Pham Tuan Anh - Deputy Director of the Department of Industry said that in order to develop the mechanical industry and increase the domestication rate, in the coming time, the ministry will continue to strongly develop downstream industries; including some industries such as the energy industry, precision mechanical industries as well as some mechanical manufacturing industries to ensure that supporting industries have conditions to develop. This will attract multinational corporations to invest in large-scale projects in Vietnam.

“ In addition, by promoting the manufacturing and assembly of finished products, the market for domestic supporting industries will be maintained and expanded, creating the premise for domestic mechanical enterprises to become suppliers and participate in the supply chain of enterprises manufacturing and assembling final products, ” said Mr. Pham Tuan Anh.

Source

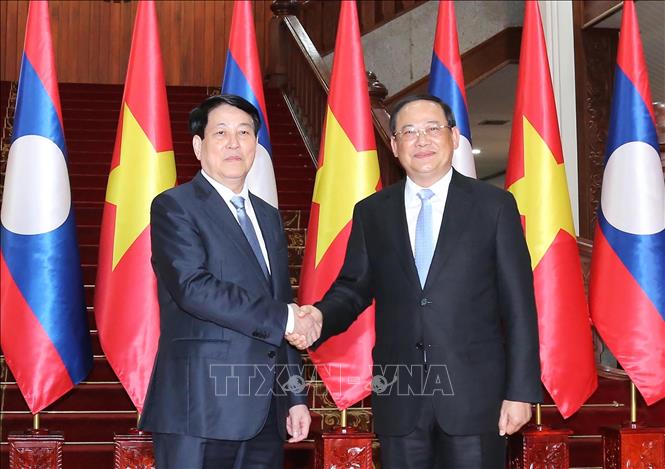

![[Photo] President Luong Cuong meets with Lao Prime Minister Sonexay Siphandone](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/3d70fe28a71c4031b03cd141cb1ed3b1)

![[Photo] Liberation of Truong Sa archipelago - A strategic feat in liberating the South and unifying the country](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/d5d3f0607a6a4156807161f0f7f92362)

![[Photo] Ho Chi Minh City welcomes a sudden increase in tourists](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/dd8c289579e64fccb12c1a50b1f59971)

Comment (0)