Low order prices while input costs increase are considered major challenges for domestic textile and garment enterprises in 2024 and 2025.

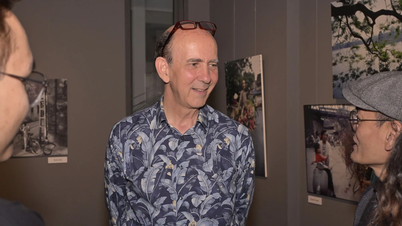

Mr. Vu Duc Giang - Chairman of Vietnam Textile and Apparel Association - had an interview with the media about this issue.

In 2024, the Vietnamese textile and garment industry is expected to reach 44 billion USD. In your opinion, what is the "secret" that helps the industry overcome so many challenges and achieve this number ?

In 2024, the Vietnamese textile and garment industry has a number of advantages. The first is the market attraction created by the country's political stability. The second attraction is the new generation of free trade agreements that are being and will be implemented, which have significantly attracted brands and investors to the industry. The third attraction comes from the shift in orders, helping domestic enterprises have abundant orders in the third and fourth quarters of 2024.

That has helped the Vietnamese textile and garment industry achieve a turnover of 44 billion USD as set out in the target. This number is very meaningful after 2023, the textile and garment industry faced many difficulties and negative growth.

|

| Mr. Vu Duc Giang - Chairman of Vietnam Textile and Apparel Association |

The industry's growth in 2024 is also a testament to the business community's relentless efforts in market planning, accepting the production of difficult products, investing heavily in production technology and applying digital management to increase labor productivity.

It is known that textile orders for the first months of 2025 are not too difficult, however, unit prices are low and green production standards of importers are increasingly 'strict'. What do you think about this opinion and what solutions do businesses in the industry have to respond?

Most textile and garment enterprises currently have orders for the first quarter of 2025 and have started negotiations for the second quarter of 2025, so the issue of orders for the first months of the year is not much of a concern.

However, businesses are facing changes in the way brands buy or the stability of orders. Orders have been negotiated, but if purchasing power slows down for only 2 weeks, partners are willing to temporarily stop production. Regarding the price of orders, it is confirmed that there will be no increase, and some partners even negotiate a decrease. However, because textile and garment businesses have actively invested in research, improved technology, automation and applied artificial intelligence in production in recent years, and applied digital management systems to improve labor productivity and optimize resources, they have helped overcome the price challenge.

At the same time, businesses develop new products based on the strengths of existing products by changing, adding or removing materials, technology, and techniques from spinning methods, fiber materials to weaving effects, dyeing technology, sewing, and packaging. Or combining two different types of materials to create different effects in the same environmental conditions.

On the other hand, some businesses have paid attention to building rooftop solar power systems, water and electricity recycling systems, etc.; replacing coal boilers in dyeing factories with other biomass materials, such as rice husks, to reduce emissions and improve efficiency; applying environmental impact measurement software in manufacturing factories right from the sample development stage to be able to evaluate the types of raw materials and technologies that impact the environment.

In 2025, Vietnam's textile and garment industry is expected to grow by about 10% compared to 2024, so the turnover must reach about 47 - 48 billion USD. To achieve this figure, the industry must face some major challenges.

First is the shortage of supply. The textile and garment industry is still dependent on imported raw materials. If it is not quickly remedied, domestic enterprises will continue to lose the advantages of signed free trade agreements. This is also one of the reasons why the Vietnam Textile and Apparel Association has continuously called for investment in the shortage of supply in recent years.

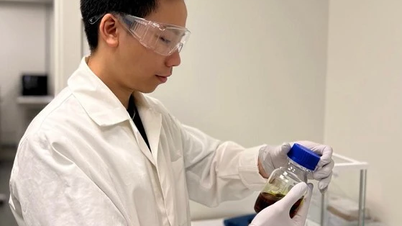

|

| Textile and garment enterprises apply advanced technology, increase production capacity, reduce costs. Photo: TH |

Green criteria and standards in production towards the sustainable growth goals of importers are increasingly difficult and numerous, forcing businesses to meet them if they do not want to lose market share. To meet them, businesses must invest, technologize, robotize, save energy, use renewable energy in production and the investment resources are not small. Along with that is the investment and assessment to obtain green certificates, this stage also requires a huge amount of resources.

Capital for investment in applying modern technology to increase labor productivity, aiming for sustainable growth is still a big challenge for businesses. What does the Association propose to overcome the difficulties, sir ?

Capital is always the 'weakness' of enterprises, not to mention investment in technology and green production always requires huge resources, while domestic textile and garment enterprises are mostly small and medium-sized.

Therefore, over the years, the association has always proposed to the Government and the State Bank to establish a fund or green financial source for businesses to access. At the same time, there is an open mechanism for businesses to proactively build relationships with credit institutions to obtain green capital for investment.

Furthermore, the capital investment for green production takes a long time to recover, so in terms of tax, should we accept businesses to include it in production costs to quickly repay the capital to the credit institution?

In the Strategy for sustainable development of the textile, garment and footwear industry to 2030, with a vision to 2035, the Government has advocated the construction of a number of industrial parks dedicated to the production of large-scale raw materials. This is essential not only to help businesses proactively source raw materials, reduce imports, reduce costs, and make good use of incentives from free trade agreements, but also to help Vietnamese textiles and garments advance higher in the supply chain. Therefore, the association hopes that the Ministry of Industry and Trade will soon coordinate with relevant units, especially localities, to deploy these industrial parks and put them into operation soon.

Thank you very much!

Source: https://congthuong.vn/ung-dung-cong-nghe-chia-khoa-giup-nganh-det-may-chinh-phuc-muc-tieu-47-48-ty-usd-363036.html

![[Photo] Welcoming ceremony for Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra on official visit to Vietnam](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/cdd9e93739c54bb2858d76c3b203b437)

![[Photo] Prime Minister Pham Minh Chinh holds talks with Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/23b5dd1e595d429491a54e3c1548fb79)

![[Photo] The Prime Ministers of Vietnam and Thailand witnessed the signing ceremony of cooperation and exchange of documents.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/935407e225f640f9ac97b85d3359c1a5)

Comment (0)