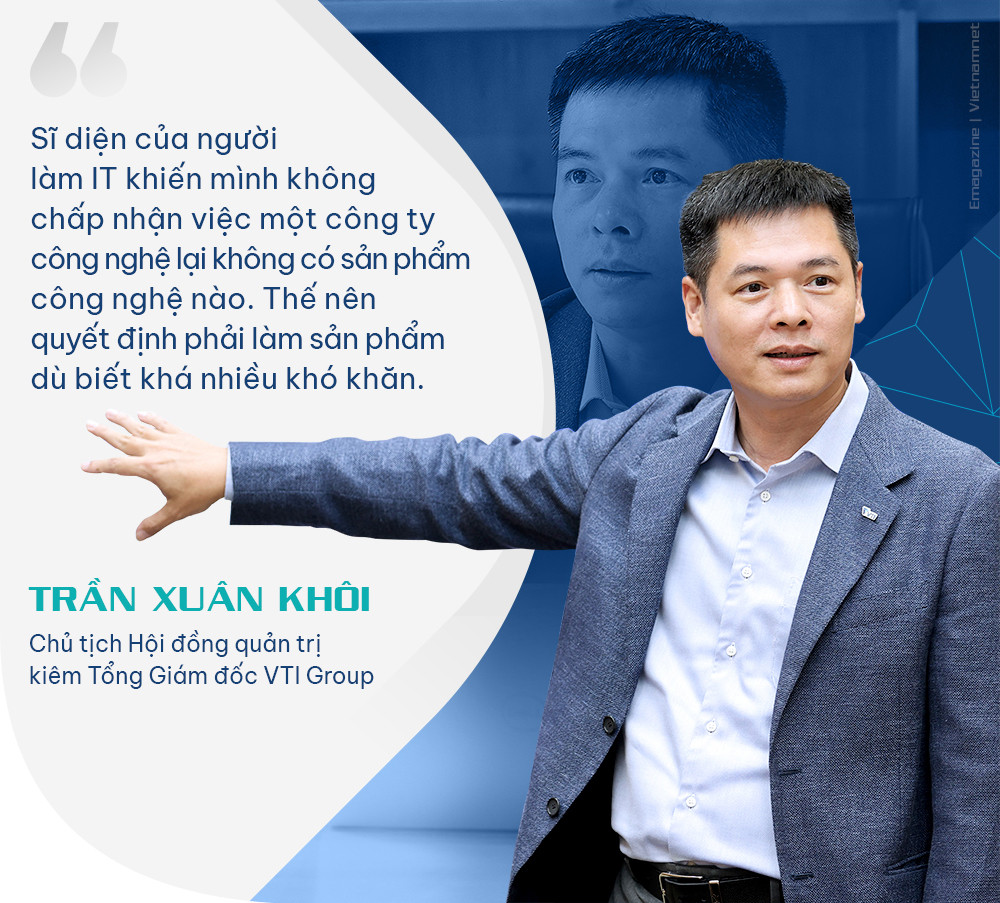

Having worked at FPT from 1996 to 2016, former Director of FPT Japan Tran Xuan Khoi felt that his new job - in charge of human resources for FPT Software - was not suitable for his passion for business, so he decided to split off and open his own company.

VTI Company was born with the meaning VTI = "Vietnam Technology International" - "Bringing Vietnamese technology to the world".

Not only simply bringing Vietnamese technology to the world, VTI also wants to use technology with customers to create many new values, so we decided to choose the slogan "Innovation Technology Value" - "Technology creates new values".

With many years of experience in the field of software outsourcing for Japanese customers, VTI started a business in this direction.

“In 2017, the Japanese outsourcing market was worth about 4 billion USD, while the largest Vietnamese company in the outsourcing sector for Japan only achieved revenue of about 100 million USD. There is still a lot of room for companies to develop. With the support and help of many friends, especially Japanese friends, VTI quickly established its own customer base,” Mr. Tran Xuan Khoi, Chairman of the Board of Directors and General Director of VTI Group, recalled the early days of the company’s establishment.

For a startup, the first 5 years are the “survival” years, deciding whether it will survive or not. VTI was very lucky to be born at a time when demand in the Japanese market was very high.

However, Japan is a demanding market, outsourcing to Japan is not an easy task.

The “newbie” VTI is not attractive enough for Japanese customers to come to them. With only 10 initial employees, it is not easy to convince customers to get large orders.

“We have focused on improving our ability to communicate in Japanese with Japanese customers. The entire management team must be fluent in Japanese. Customers feel more secure when they see that everyone at VTI speaks Japanese. Instead of introducing the company's past projects, we introduce the experience of VTI's staff, our determination to carry out special projects, projects that customers are facing difficulties,” Mr. Khoi shared the secret to conquering Japanese customers.

The first period was a series of "hard work" for Mr. Khoi, when there were no customers, and the monthly operating costs of the company were not small. Wherever there was a customer contact, he quickly sought to connect, no matter where the customer was. Once, he heard that a Japanese customer was in Saigon, without an appointment, but he still traveled a long way to meet him, and this is still one of VTI's major customers.

“All beginnings are difficult”, but with strong will and perseverance, VTI has gradually reaped the rewards.

After 6 years of establishment, VTI has more than 1,200 employees. VTI Group's current revenue comes mostly from the IT sector, of which 90% is from outsourcing.

Until now, the "general manager" of VTI still believes that software outsourcing is a good solution to help Vietnamese businesses quickly develop and accumulate finance to realize their dreams.

Software outsourcing for Japanese customers not only brings in revenue but also helps Vietnamese businesses accumulate more knowledge and experience. However, most outsourcing businesses only stop at the level of bringing skilled Vietnamese people to the world, but have not yet brought much Vietnamese technology to the world.

At the end of 2020, Mr. Khoi decided to develop VTI not only as an outsourcing company but also as a technology product company.

“The pride of an IT worker makes me not accept that a technology company does not have any technology products. So I decided to make a product even though I knew it would be difficult because I had no experience. My brothers and I started with just one sentence: We are good engineers of Vietnam. Engineers have to make products,” Mr. Khoi said, smiling.

Through the process of working on projects with customers and directly surveying factories in Vietnam, Mr. Khoi and his colleagues realized that the level of information technology application of these factories is still quite low. Some very large-scale enterprises, investing millions of USD in ERP systems, but the production system management part still uses ledgers, Excel software, and even manual recording.

Market analysis shows that the whole country has more than 60,000 factories, this is an opportunity for VTI to make products.

With the knowledge accumulated after working with Japanese manufacturing enterprises, VTI has researched and developed a Production Execution Management Solution called MES-X. This solution helps enterprises update production information at each stage, determine the productivity of each factory, loss, number of defective products..., thereby finding ways to improve the stage when necessary.

In late 2020 and early 2021, the Production Execution Management Solution is not new, but in the Vietnamese market, it mainly supplies foreign products, the price is quite high, and it is not easy to change and adjust to suit the reality of each business.

VTI's solution attracts the attention of many enterprises with factories operating in Vietnam because of its cheaper price, quality equivalent to foreign goods, and the ability to customize products according to actual requirements. VTI's products are of special interest and welcome to FDI enterprises.

Besides MES-X, VTI also focuses on researching and developing many other products and solutions related to improving production efficiency such as IoT Gateway, Remote Controller, etc. Of which, there are about 5-6 products related to new technologies such as AI (artificial intelligence), Internet of Things (IoT), etc., with the characteristic of software solutions accompanying hardware. There are many software companies on the market, but very few companies can make accompanying hardware like VTI.

In 2021, the MMS-X Equipment Maintenance and Maintenance Management Solution researched and developed by VTI helped a textile factory effectively control the operation of 18,000 devices. Sensor devices will collect signals from machines, provide data to the system about real-time operation as well as notify when each machine needs maintenance and warranty so that management can promptly plan, thereby increasing production efficiency.

VTI's production support solutions and products have been and are being deployed for many customers in the packaging, pharmaceutical, electronic components, and gemstone industries...

VTI's product portfolio serving domestic and international customers is now quite extensive. In addition to MES-X (VTI is negotiating a contract with a Japanese ice cream factory, worth about 10 million USD), there is also the FaceX facial recognition timekeeping device that has begun to be deployed in Japan.

Or the license plate recognition solution helps dealers of a Japanese car company in Vietnam identify customers. The ParkingX license plate recognition system is also applied to factories with tens of thousands of workers to shorten the time workers spend parking their cars in the parking lot.

Some other products include: Virtual receptionist supporting guest reception for the largest German logistics company located in Ho Chi Minh City; Bus student management system software, applied for a Japanese school based in My Dinh (Hanoi); Software solution serving nearly a dozen retail chains in Japan, to be deployed in Vietnam...

As one of the customers using facial recognition products researched and developed by VTI, Ms. Nguyen Quynh Lien, General Director of Harmony Advanced Technologies, shared: “We have considered many suppliers, but VTI's products have the strength of providing a complete solution including both hardware and software, unlike some suppliers that only provide hardware or software, causing the purchasing unit to have more work. Along with that, VTI's sales team is very good, whenever I have any questions, they answer very enthusiastically. More importantly, VTI's products are products of Vietnamese companies, and as a Vietnamese enterprise, I support Vietnamese enterprises."

“We will officially start selling products from 2022. Before that, we only made products and did not sell them. Last year, VTI invested quite a lot in products, up to more than 1 million USD. This year, we are likely to continue to invest in product research and development (R&D) for several years. Up to now, the products are still in the process of being regularly upgraded to meet market demand. We are ready to do it “to the end”. The increase in customers thanks to consulting, customers signing contracts, implementing... is encouraging VTI to continue on the path of making technology products, striving to increase the revenue ratio of technology products to 30% of total revenue by 2027”, Mr. Khoi frankly shared.

Up to now, VTI's technology products have been present in Japan, with very competitive prices compared to similar products on the market. Given the fact that many Japanese people still trust Japanese products more than Vietnamese products, the VTI team continues to make efforts to convince customers, even willing to deploy them for free at first.

“When we bring our products to exhibitions and fairs about production in Japan, many customers are interested. There are about 10 Japanese customers researching VTI products. I am sure that this year or at most early next year, there will be some contracts signed,” Mr. Khoi happily revealed.

2023 is identified by VTI leaders as the year of "Go Global" - "Going out to the world market".

Regarding outsourcing, in addition to the main market of Japan, VTI has just established branches in Korea and Singapore; it is expected to open another branch in Malaysia next November.

Sharing his subjective feelings about the great difficulties on the Go Global journey, the "captain" of VTI commented: The shortage of experienced engineers is always a difficult problem, while highly qualified human resources are one of the deciding factors in whether or not to dominate the market.

“The world market is still very vast. We must be bold. But we should have a certain understanding and not go in haphazardly. The market and customers are becoming more and more demanding. We must understand the market to a certain extent, otherwise we will just waste money,” Mr. Khoi shared a few words with businesses that share the goal of “reaching the big sea”.

The phrase “Kaizen” (improvement) in Japanese or the English sentence “Continuous improvement is better than delay perfection” – “It is more important for us to improve regularly than to wait until perfection” is often used by Mr. Khoi as a “compass” for VTI’s business activities. According to him, countries like Japan, China, Korea… have all succeeded with this direction, they started by making basic products, then improved the products and conquered the world market.

That “compass” is continuing to motivate VTI to accelerate the realization of its goal of reaching 100 million USD in revenue and going public in the near future.

Article: Dawn

Photo: Le Anh Dung

Design: Nguyen Ngoc

Vietnamnet.vn

![[Photo] Prime Minister Pham Minh Chinh works with the Standing Committee of Thai Binh Provincial Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/f514ab990c544e05a446f77bba59c7d1)

![[Photo] Prime Minister Pham Minh Chinh receives Swedish Minister of International Development Cooperation and Foreign Trade](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/ae50d0bb57584fd1bbe1cd77d9ad6d97)

![[Photo] Prime Minister Pham Minh Chinh starts construction of vital highway through Thai Binh and Nam Dinh](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/52d98584ccea4c8dbf7c7f7484433af5)

Comment (0)