Born hundreds of years ago and increasingly developing, the traditional fish sauce production profession has supported many generations of people in My Thuy village, Hai An commune, Hai Lang district. In 2012, Quang Tri province recognized the traditional fish sauce craft village of My Thuy, thereby creating motivation for the craft village to expand. In addition to maintaining and constantly improving product quality, My Thuy people always focus on clean production, ensuring food hygiene and safety (FSH) to maintain the brand of their hometown fish sauce.

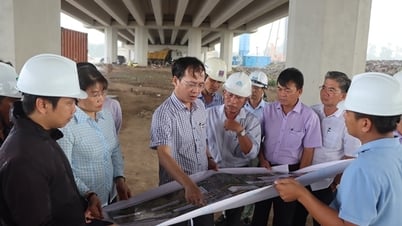

Fish sauce production at Mr. Dang Quang Le's household, My Thuy village, Hai An commune, Hai Lang district - Photo: D.V

My Thuy traditional fish sauce, Hai An commune has long been famous far and wide, trusted by people in Hai Lang district and many localities inside and outside the province. In addition to maintaining the quality and traditional flavor, the production stages and ensuring food safety for My Thuy fish sauce products are also focused on.

Mr. Dang Hai Nhan, Head of the My Thuy Fish Sauce Production Cooperative, said that the group has 5 participating households and on average sells a total output of about 10,000 liters of fish sauce to the market each month. By joining the cooperative, households join together to produce fish sauce and connect to consume large orders.

In addition, households also share and support each other in terms of experience, application of science , technology and techniques in production and environmental protection. Mr. Nhan said that in order to maintain the profession sustainably, each production household must be self-aware and uphold responsibility in production with the goal of making truly clean products, ensuring the best quality.

“According to the production process, we buy fresh fish (or fermented fish) from Cua Viet port and Thuan An port, Thua Thien Hue to ferment salt into fish sauce. Depending on the type of fish, after 6 months, 9 months, or 12 months, we will filter the fish sauce. During the production process, we always ensure the facility is clean and airy; the fermentation area, the fish sauce storage area, the fish sauce extraction area, and the bottling area are separated from each other to prevent the risk of bacterial contamination. All production tools are covered to avoid insects; after production and processing, they are thoroughly cleaned,” Mr. Nhan shared.

In recent times, Hai An Commune Health Station has coordinated with local authorities, relevant agencies and units at higher levels to actively inspect and supervise food production and processing establishments in the area, including fish sauce production establishments. This work is especially focused on during holidays, Tet and the Month of Action for Food Safety. At the same time, officers and employees of the station regularly disseminate regulations on hygiene conditions of establishments, equipment, and tools in food production, processing and trading. Propagate establishments to only use raw materials with clear origin and origin, food additives, processing aids that are permitted to be used, in the correct dosage, and for the right subjects according to regulations in food production and processing. Propagate to ensure conditions for preserving and trading food in general and fish sauce products and post-production by-products in particular... Disseminate knowledge on preventing the risk of food poisoning, warn of the risk of food safety incidents. With the attention of relevant levels, sectors and grassroots health agencies in implementing food safety and hygiene supervision, it has contributed to effectively preventing food poisoning and food-borne diseases for the whole community. Head of Hai An Commune Health Station Ho Ngoc Cuong |

Like many families producing fish sauce in My Thuy village, Mr. Dang Quang Le and his wife have been in this profession since they first got married. From a small-scale facility, his family has gradually expanded the scale of production. On average, Mr. Le's facility produces 100-150 liters of fish sauce per day, most of which is consumed within the day.

“My Thuy fish sauce now has a brand name, and is trusted by many customers near and far, so our business is increasingly favorable. Being aware of that, every family tries to produce cleanly, strictly ensuring food safety and hygiene conditions,” said Mr. Le.

Vice Chairman of Hai An Commune People's Committee Nguyen Cong Tuan said that after being recognized by Quang Tri Provincial People's Committee as a traditional craft village in 2012, in 2018, My Thuy fish sauce traditional craft village was granted the "My Thuy fish sauce brand" certificate by the Intellectual Property Office; and was granted a certificate of typical products at the district level in 2018. My Thuy village currently has 41 households participating in fish sauce production, of which 28 households have registered for business and have full certificates of food safety and hygiene registration. The remaining households are continuing to receive support from the locality to register for procedures for granting certificates of food safety and hygiene.

In recent years, the traditional craft village of My Thuy fish sauce has exported an estimated 900,000 - 1 million liters to the market each year, with a total annual revenue of 42 - 45 billion VND. At the same time, the craft village has also created regular jobs for about 200 workers with stable income.

Vice Chairman of the Commune People's Committee Nguyen Cong Tuan said that the locality regularly inspects and reminds people to preserve the production environment and strictly comply with food safety regulations. Regulations require each household to have a trash can to collect waste; damaged or unused tools, bottles, jars, and packaging must be transferred to the district landfill for treatment and destruction. "In particular, My Thuy traditional fish sauce is completely free of additives and preservatives, so it is clean and safe," Mr. Tuan affirmed.

To maintain and improve the quality of My Thuy traditional fish sauce, Mr. Tuan suggested: "Superiors need to continue to pay attention to opening training classes and transferring science and technology to people inside and outside the craft village.

Provide financial support for craft villages in environmental protection, wastewater treatment and machinery to develop craft villages. In the long term, the locality recommends that all levels plan concentrated production areas for craft villages in a reasonable manner, far from residential areas to ensure sustainable production.

Hieu Giang

Source

![[Photo] Prime Minister Pham Minh Chinh and Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra attend the Vietnam-Thailand Business Forum 2025](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/1cdfce54d25c48a68ae6fb9204f2171a)

![[Photo] President Luong Cuong receives Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/52c73b27198a4e12bd6a903d1c218846)

Comment (0)