Not only mastering the world's advanced road tunneling technology, Deo Ca Group's engineers also created a new tunnel construction solution to help speed up progress and ensure safety and quality of the project.

|

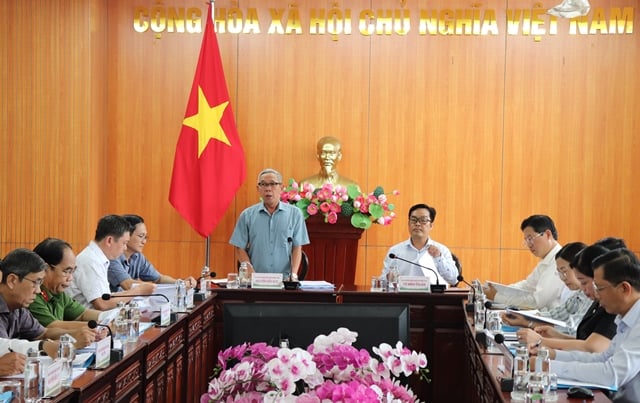

| Construction of road tunnel No. 3 of the Quang Ngai - Hoai Nhon expressway component project using the Deo Ca system construction method. |

Fans of famous documentary series about the construction of super-large, unique construction projects such as MegaStructures or How It's Made of Discovery Channel will certainly be very excited to witness the construction of road tunnel No. 3 at the North-South Expressway Component Project, Quang Ngai - Hoai Nhon section, constructed by Deo Ca Group because of the intelligent construction organization method, with a very high degree of rationality.

The Quang Ngai – Hoai Nhon Expressway Component Project has 3 road tunnels, of which the 3,200 m long road tunnel No. 3 connecting Quang Ngai and Binh Dinh provinces is the most difficult and challenging item. This is also the longest road tunnel in the North – South Eastern Expressway Construction Project, phase 2021 – 2025.

In road category 3, Deo Ca Group must complete the construction of two parallel tunnels, each 3,200 m long, passing through a complex geological zone within 42 months.

However, with many years of experience in road tunnel construction, possessing a team of skilled engineers and technicians and the most modern tunnel construction equipment in Vietnam today, Deo Ca Group aims to open this road tunnel earlier than planned, in June 2025, moving towards opening the entire Quang Ngai - Hoai Nhon expressway to technical traffic by the end of December 2025.

As of the end of August 2024, at the No. 3 road tunnel project, the construction work was carried out by Deo Ca Group 24/24 hours in accordance with the spirit of "3 shifts 4 teams" launched by the Prime Minister. Of which, the left tunnel has dug 1,500m/3,200m, the right tunnel has dug 1,619m/3,200m. The progress and quality of construction of this item are closely following the plan and set goals.

At Road Tunnel No. 3, Deo Ca Group has deployed a unique tunnel construction method, called “Deo Ca tunnel construction”. This is a tunnel construction method that Deo Ca Group has applied and created based on the Austrian NATM tunneling technology to shorten the progress and ensure quality and safety for workers.

The unique feature of this road tunnel construction method is the solution to increase space during tunnel construction by dividing the tunnel into many small tunnels combined with inclined face excavation and spraying reinforcement immediately after excavation.

The purpose is to shorten construction time and increase the load-bearing safety of the construction structure, overcoming the design with a shape that is not optimal in terms of the load-bearing capacity of the tunnel.

Specifically, Deo Ca Group is organizing the construction of road tunnel No. 3 by increasing the access space combined with spraying reinforcement immediately after excavation, including the main steps: dividing the tunnel face into 2 parts: the upper part (arch part) and the lower part (wall part) with the height of each part depending on the height of the drilling machine.

The construction units also divided the upper part of the tunnel into 2 parts, part 1 was dug first with a span of less than 9.5m, part 2 was dug after part 1 was dug and dug with many different spaces or dug to the horizontal tunnel. The lower part of the tunnel was divided into 3 parts, part 1 was dug into many construction points, part 2 was dug once and used the horizontal drilling method, drilling the hole without blasting, part 3 was dug similar to part 1.

For projects with 2 parallel tunnels designed to be horizontally connected, use the horizontal passage as a circulation route and divide into many independent tunnels to create more construction space.

In fact, this solution has been researched and successfully applied by Deo Ca Group during the construction of tunnel No. 2 - Package XL2, tunnel No. 1 - Package XL1 of the Quang Ngai - Hoai Nhon Component Project and has brought about remarkable results.

At these two tunnels, the contractor completed the tunnel construction 3 to 4 months ahead of schedule, meeting the requirements of structural safety, construction safety, project quality and improving production and business efficiency.

According to Mr. Bui Hong Dang, Director of the Tunnel Command Board of the Quang Ngai - Hoai Nhon Expressway Component Project, in reality, the traditional tunneling method only has one space for one construction head, while this method researched by Deo Ca will have at least two spaces for each head, helping to speed up construction progress and at the same time improve project efficiency.

It is known that the invention of the method of constructing road tunnels by increasing the access space combined with spraying reinforcement immediately after digging by Deo Ca Group has been approved by the Intellectual Property Office in the form of a registration application. This is a solution to shorten construction time and increase the load-bearing safety of the construction structure.

According to Mr. Vu Van Phuong, Team Leader of Road Tunnel Drilling Team No. 3 - who has 16 years of experience in road tunnel construction, the Deo Ca tunnel construction plan has been compiled by Deo Ca Group into a handbook, providing instructions to engineers and technicians in the entire unit.

As someone who has been following road tunnel projects for many years, Associate Professor Tran Chung, former Director of the State Appraisal Department of Construction Quality (Ministry of Construction), commented that tunnel construction has two difficult problems.

One is the complex geological survey, many sections go through weak soil, fault areas, and interspersed rocks and soil, so it is necessary to calculate and organize reasonable excavation steps, otherwise there will be landslides.

Second is quality control in the tunnel, just a torn waterproof layer can endanger the entire project. Road construction will require cutting down mountains, inevitably destroying the environment. Therefore, Mr. Chung believes that a more sustainable solution is to build a tunnel through the mountain, both preserving the landscape and avoiding landslides. However, safety must be the top priority because there are often toxic gases in the mountains, while ensuring technical safety, the construction unit must also manage safety.

According to Mr. Chung, the biggest benefit of building road tunnels over the past 10 years is that the team of Vietnamese engineers and workers have inherited and mastered advanced tunnel drilling technology and risk control.

“The Deo Ca, Cu Mong or Hai Van 2 tunnels and especially the road tunnel projects on the North-South expressway such as Thung Thi, Truong Vinh and road tunnel No. 3 of the Quang Ngai - Hoai Nhon expressway have affirmed that the Vietnamese people have the courage and intelligence to do, and even do better than, what advanced countries have done and are doing,” Mr. Chung assessed.

Source: https://baodautu.vn/doc-dao-cong-nghe-thi-cong-ham-duong-bo-theo-he-deo-ca-d223439.html

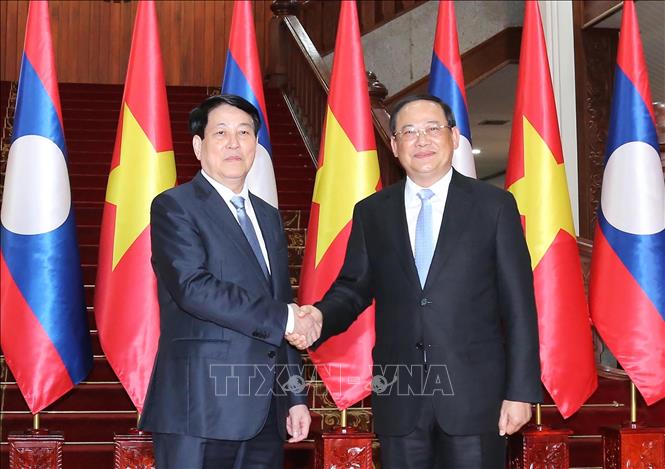

![[Photo] President Luong Cuong meets with Lao Prime Minister Sonexay Siphandone](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/3d70fe28a71c4031b03cd141cb1ed3b1)

![[Photo] Liberation of Truong Sa archipelago - A strategic feat in liberating the South and unifying the country](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/d5d3f0607a6a4156807161f0f7f92362)

![[Photo] Ho Chi Minh City welcomes a sudden increase in tourists](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/dd8c289579e64fccb12c1a50b1f59971)

![[Photo series] 'Children become soldiers' recreates the image of the historic victory in Spring 1975](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/25/e6bb6af778714d58bd8727f9802f4090)

Comment (0)