Promote the spirit of production

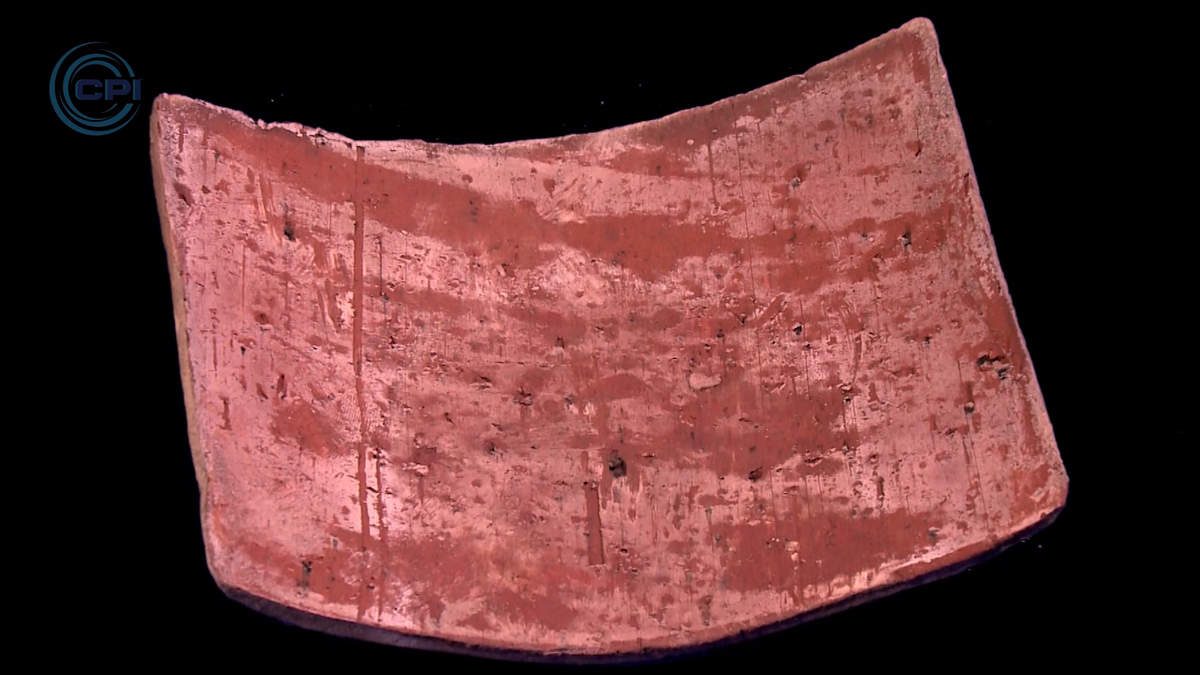

At the Raw Materials - Separation Workshop, the competitive atmosphere of production and labor these days is more focused than ever. Workers actively implement production processes and safety controls to ensure stable operation of the line.

Having just finished patrolling the grinding area, workshop worker Tong Van Tien continued to carefully walk around the production area to closely observe the equipment once more.

Mr. Tien said that since it is the final stage, everything is thoroughly implemented by the company. All employees are always aware of the competition goals in the last months of the year.

That is to both complete production and business targets well and ensure plans for equipment repair and maintenance in the workshop. These tasks will help ensure stability, safety, continuity and efficiency for the entire company.

Union organizations also increase propaganda through forms such as: directly, union information page, workshop zalo group... Thereby, so that workers can work side by side with the company to complete each goal in stages.

Along with strictly following the regulations in production, Mr. Van Tien Hung, a worker of the Raw Materials - Separation Workshop, always pays attention to ensuring health and safety regulations before, during and after his shift. During the production shift, he always complies well and is fully equipped with labor protection equipment.

“During the inspection process, we always pay attention to unusual factors, promptly detect and eliminate risks that cause unsafe production,” Mr. Hung shared.

The workshop always encourages and creates conditions for workers to promote technical innovation initiatives. Many plans and projects are registered with the company and superiors to rationalize and optimize production, save labor, and improve conditions for workers.

Mr. Phung Van Tai, Deputy Manager of Hydrate Calcining Workshop, said that in order to complete the plan set forth by the company's leadership, the unit always develops a specific implementation plan.

In terms of human resources, the unit regularly urges workers to increase inspection work to ensure that the equipment of the production line is stable throughout. Determined not to let type 2 and 3 incidents occur that affect the progress of the plan.

In terms of equipment, the company has prepared materials for regular maintenance and repair. The unit also disassembles equipment in the main line and plans special maintenance and inspection. Thereby helping the equipment operate at its best during the last 3 months of the fourth quarter.

Along with the set output, safety work must also be ensured regularly. The company always urges and closely supervises shifts, increases patrol work, especially the third shift. From there, workers see the importance of completing the set plan in the last months of this year.

90 day and night competition

In 2024, Dak Nong Aluminum Company - TKV encountered many difficulties and problems in compensation, site clearance and resettlement.

People often illegally gather in large numbers within the company's management boundaries to obstruct production activities as well as project implementation of the unit.

This leads to the inability to organize the exploitation and transportation of ore. At some point, the processing plant has to stop operating.

The alumina factory has to run at low load (below 50% capacity), directly affecting the unit's production and business plans as well as reducing local budget revenue in 2024...

“The difficulties of the first months of the year will put great pressure on the final quarter of the year, forcing the entire company to make every effort,” said Mr. Phung Van Tai, Deputy Manager of the Hydrate Calcining Workshop.

Promoting the tradition of "Discipline - Unity", from October 1 to December 31, 2024, Dak Nong Aluminum Company - TKV is launching a 90-day and night competition to boost production and complete the 2024 target.

The activity aims to propagate and educate cadres and workers to enhance their sense of responsibility, promote their spirit of enthusiastic work, dynamism and creativity, overcome difficulties, and successfully achieve production and business goals.

During the emulation process, the unit will have forms of rewards for collectives and individuals with achievements in striving to comprehensively complete the 2024 production and business plan assigned by the Vietnam National Coal - Mineral Industries Group.

Specifically, in 90 days and nights, Dak Nong Aluminum Company strives to achieve a production output of over 183.7 thousand tons of converted alumina. This will contribute to ensuring the completion of the 2024 plan of over 685 thousand tons of converted alumina.

In 90 days and nights, Dak Nong Aluminum Company strives to achieve a production output of over 183.7 thousand tons of converted alumina. This will contribute to ensuring the completion of the 2024 plan of over 685 thousand tons of converted alumina.

At the same time, the company ensures security, labor safety and hygiene, and environmental safety, with the determination to not allow violations in management and during work performance.

The company coordinates with local authorities and units to effectively implement contents related to compensation and site clearance.

The company strives to have over 30 hectares of clean land exploited in the fourth quarter. Raw ore output will reach over 1.65 million tons, ensuring the completion of the 2024 plan of 378 million tons.

Source: https://baodaknong.vn/cong-ty-nhom-dak-nong-tang-toc-de-dat-tren-685-000-tan-alumin-233558.html

Comment (0)