Because artificial sand is expensive and sea sand has only been studied on a small scale, many experts believe that we should utilize thermal power plant ash, blast furnace slag, and river and lake mud as roadbed materials.

Natural sand (river sand) is used for two main purposes. A high-quality type is used to make mortar and concrete, also known as construction aggregate sand. A lower-quality natural sand is used to build roadbeds and civil works. According to the Institute of Construction Materials, the average annual demand for construction aggregate sand nationwide is about 130 million m3, and for filling sand is 550 million m3.

The most popular alternative to natural sand today is artificial sand (crushed sand) from quarries. The advantage of crushed sand is that it costs 200,000-250,000 VND/m3, while the price of river sand is 400,000-500,000 VND/m3, so it can reduce construction costs. However, crushed sand is not feasible if used for landfill because the state unit price for landfill sand is about 80,000 VND/m3.

Sea sand is a promising alternative material source because Vietnam has 30 exploitable sea areas with a total estimated resource of nearly 150 billion m3. However, there is currently only TCVN 13754:2023 standard for saline sand for concrete and mortar, there is no standard for sea sand as an alternative material to filling sand. The pilot project of sea sand for new roadbed construction is on a small scale.

Coal waste rock and soil in Quang Ninh are proposed as landfill material. Photo: Minh Cuong

Utilizing industrial waste sources

Because crushed sand is expensive, sea sand has only been studied for use on a small scale. Mr. Le Viet Hung, Deputy Director of the Cement and Concrete Center (Institute of Construction Materials), said that it is possible to replace landfill sand with thermal power ash and slag, metallurgical slag such as blast furnace slag and steel slag.

Thermal power ash and slag can be used as a potential source of land fill or as raw material for cement production, because thermal power plants discharge about 16 million tons of waste each year. Currently, the country still has about 48 million tons of ash and slag remaining in landfills, which need to be recycled to reduce environmental pollution and replace natural sand in transportation projects.

The source of blast furnace slag at steel factories is estimated at 4.6 million tons per year, and steel slag is 3.9 million tons, which is also an alternative material. Not only used for foundation and leveling, it is also an aggregate for concrete. The advantage of this material is its low price, equivalent to the price of sand for leveling, however, steel factories are concentrated in the North and Central regions; the South, where the North-South expressway project is lacking sand, has only a few steel factories in Ba Ria - Vung Tau.

According to Mr. Hung, phosphorous gypsum from DAP fertilizer factories can be used as an additive for cement or as a filling material. Each factory can exploit nearly 2 million tons per year. Mining tailings and coal waste from coal mines in Quang Ninh can be potential filling materials. Every year, coal mines dump about 150 million cubic meters of rock and soil into landfills, occupying thousands of hectares of land.

Dredged sludge from rivers can also be a source of foundation material, contributing to environmental protection. However, sludge has high humidity, contains clay and organic impurities, so it must be treated such as reducing moisture, mixing with other materials such as sand and stone if used as foundation material.

Another source is waste from construction projects such as bricks, tiles, and concrete that has been processed and crushed, which can also be used as foundation or as concrete aggregate for construction projects. However, not many provinces and cities currently have production lines for recycling construction waste.

Experience in using natural sand substitutes in India

According to experts, Vietnam can learn from how India has dealt with the shortage of construction sand and the escalating crime rate in the fight over illegal sand mining. The country has promoted many alternative materials such as artificial sand, sand recycled from construction waste, and ash and slag.

Ash is produced from the operation of coal-fired power plants, mainly consisting of minerals, clay, quartz and other impurities contained in coal. In terms of properties, ash is coarser and heavier than fly ash, so it can be used to partially replace sand in concrete production, used as roadbed material, and improved agricultural land.

According to the Indian environment agency, the use of fly ash not only reduces dependence on river sand but also helps reduce the amount of waste sent to landfills, avoiding adverse impacts on the environment. The agency also recommends that fly ash must meet safety, environmental and material standards before being used in construction projects.

In addition, India also encourages construction waste recycling plants to replace natural sand. Concrete from demolished buildings can be crushed to the appropriate size to make cement. Similar recycling methods are also applied to glass, plastic, bricks, tiles, ceramics, and porcelain. However, the application of these materials is not popular due to difficulties in ensuring construction and landfill standards.

What to do to promote the production of materials to replace natural sand?

According to Mr. Le Viet Hung, the current difficulty is that the technical standards for materials replacing natural sand are not complete, so there is not enough legal basis for their use. State agencies have just issued standards for filling materials such as thermal power ash and construction waste. The Ministry of Construction has only provided guidance on the use of phosphorous gypsum from DAP fertilizer plants, but there are no standards yet. Alternative materials such as tailings, river mud, sea sand, coal waste rock and soil, etc. do not have standards yet.

Mr. Le Trung Thanh, Director of the Department of Construction Materials (Ministry of Construction), also said that the standards and technical and economic norms for the production and use of crushed sand have been issued, but they are not yet complete for all types of alternative materials. The incentive mechanism for production facilities and organizations and individuals consuming products that replace natural sand is not specific.

Therefore, in the coming time, ministries and branches need to continue to improve institutions, tax incentives, and legal regulations to promote people and businesses to produce and consume materials that replace natural sand. Specialized agencies should strengthen research and widely apply technology to produce artificial sand and sand replacement materials to improve quality and reduce product costs.

Dr. Thai Duy Sam, Vice President of the Vietnam Association of Building Materials, proposed that the government should have a mechanism of tax incentives and interest rate support to help businesses invest in equipment to recycle materials such as ash, slag, and construction waste, so that these materials have low prices to compete with natural sand. Because using materials to replace natural sand not only meets the future demand for building materials but also protects the environment. The government should also stipulate that businesses that emit waste must recycle themselves, or be responsible for cooperating with other businesses to recycle.

In 2020, the Government approved the Strategy for Development of Vietnam's Construction Materials for the 2021-2030 period, with a vision to 2050, which requires industries to promote research and development of new materials and new technologies, using waste as alternative raw materials; at the same time, research advanced and safe mining technology, minimizing factors affecting the landscape and environment.

Source link

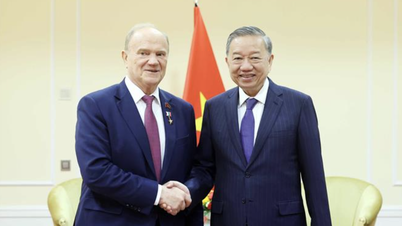

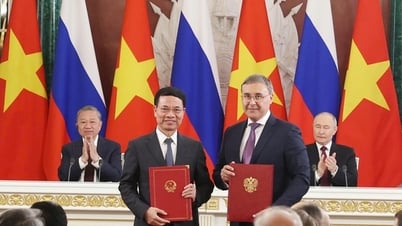

![[Photo] General Secretary To Lam meets and expresses gratitude to Vietnam's Belarusian friends](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/c515ee2054c54a87aa8a7cb520f2fa6e)

![[Photo] General Secretary To Lam arrives in Minsk, begins state visit to Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/76602f587468437f8b5b7104495f444d)

![[Photo] General Secretary To Lam concludes visit to Russia, departs for Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/0acf1081a95e4b1d9886c67fdafd95ed)

![[Photo] National Assembly Chairman Tran Thanh Man attends the Party Congress of the Committee for Culture and Social Affairs](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/f5ed02beb9404bca998a08b34ef255a6)

Comment (0)