Just half a year after launching AGV robots for sorting goods in early 2024, Viettel Post "launched" a fleet of hundreds of modern robots of all kinds that they produced themselves. 10 technologies according to the 4 core stages of the logistics chain have been developed to gradually implement the strategy of building a national logistics infrastructure.

Getting rid of the "postman" label, Viettel Post becomes a logistics technology company

Just half a year after launching AGV robots for sorting goods in early 2024, Viettel Post "launched" a fleet of hundreds of modern robots of all kinds that they produced themselves. 10 technologies according to the 4 core stages of the logistics chain have been developed to gradually implement the strategy of building a national logistics infrastructure.

In early 2024, Viettel Post's Smart Sorting Technology Complex located in Quang Minh Industrial Park, Hanoi put 200 AGV sorting robots into use. Because Viettel Post is the first enterprise to 'dare' to invest in new technology on such a large scale, this event is considered a milestone in the Vietnamese logistics industry in 2024. At that time, robots were purchased from abroad and Vietnamese engineers mastered the operating technology.

But surprisingly, just half a year later, a modern robot system “Made by Viettel Post” appeared and officially went into operation in the Exploitation Centers.

|

| Owning the most modern logistics technology, Viettel Post has become a bright spot in Vietnam's logistics industry. |

Viettel Post produces robots, providing a chain of complete automation solutions

It is known that after using the imported AGV robot system and realizing the limitations of the system, Viettel Post has developed its own version of the robot generation. With this success, Viettel Post not only masters the robot control system but also becomes the first logistics company in Vietnam to master both hardware and software: providing AGV robots whose entire control circuit, internal components and programming system are all researched and developed by Vietnamese engineers, Viettel Post.

AGV Sorting Robots – born after 6 months of research – use sensor technology and magnetic positioning systems to navigate the workspace without human intervention. This group of robots is capable of automatically sorting goods, moving at high speeds of up to 2m/s, saving 40% compared to other sorting systems.

AGV Picking Robot - only took 3 months from research to production - uses QRCode positioning technology, Lidar sensor to integrate, connect with robot hardware, apply to operation, transport goods in Fulfillment warehouses.

|

| Viettel Post has mastered robot manufacturing technology. |

Viettel Post has planned to commercialize the “Made by Viettel Post” robot for the external market by the end of this year, after operating in internal warehouses and successfully testing in the factories of some major customers. From there, Viettel Post will move towards providing a fully automated solution for transporting goods to serve production for partners.

Going beyond the warehouse and factory areas, up to now, Viettel Post has built 10 technology groups according to 4 core stages of the logistics chain (including warehouse - transportation - customs clearance - last-mile delivery supply chain system) to complete a chain of complete automation solutions to help optimize the movement of goods from the place of production to the hands of consumers.

The chain of automation solutions that Viettel Post builds is the technological foundation for Viettel's national logistics infrastructure construction strategy, including logistics parks, smart border gates, and dry ports - infrastructures connecting goods between Vietnam, the region, and the world.

Mastering technology , building cross-border logistics infrastructure

As planned, Viettel Post will develop logistics parks, including a large border gate center, realizing the strategy of "Bringing border gates from the border deep into the interior" announced at the beginning of the year.

Viettel Post Logistics Park combined with the smart border gate project provides a complete logistics solution including transportation, warehousing, customs clearance, quarantine, import and export... right inland. Thus, a closed supply chain for cross-border logistics will be formed, expected to shorten customs clearance time by 40%, improve warehouse efficiency by 30%, and reduce warehouse management costs by 25%.

|

| Viettel Post's modern technologies will simultaneously appear at the logistics park to be opened in December 2024. |

The special thing here is that Viettel Post owns all the software for registration, centralized management, coordination, supervision, and simulation at the Logistics Park. Along with that, TMS (transportation management system) technology, ERP (enterprise resource planning) technology, smart warehouse management technology (WMS)... help plan, implement, and optimize customs clearance, freight transport, and smart warehouse management.

These are also technologies that Viettel Post has developed itself, applied in its service chain and proven effective. The most modern technologies in the Logistics industry today are all applied here and are all developed by Viettel Post engineers.

Source: https://baodautu.vn/thoat-mac-anh-buu-ta-viettel-post-tro-thanh-cong-ty-cong-nghe-logistics-d231525.html

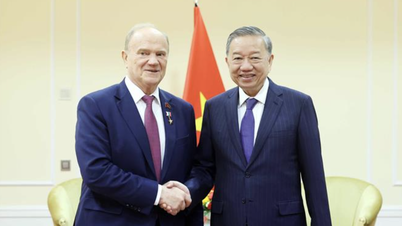

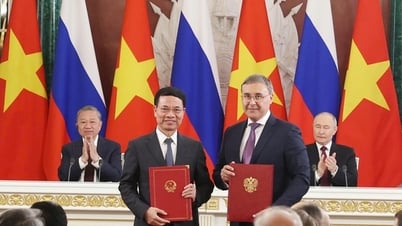

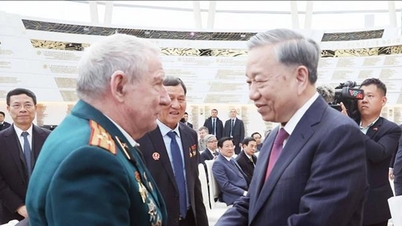

![[Photo] General Secretary To Lam meets and expresses gratitude to Vietnam's Belarusian friends](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/c515ee2054c54a87aa8a7cb520f2fa6e)

![[Photo] General Secretary To Lam arrives in Minsk, begins state visit to Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/76602f587468437f8b5b7104495f444d)

![[Photo] General Secretary To Lam concludes visit to Russia, departs for Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/0acf1081a95e4b1d9886c67fdafd95ed)

![[Photo] National Assembly Chairman Tran Thanh Man attends the Party Congress of the Committee for Culture and Social Affairs](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/f5ed02beb9404bca998a08b34ef255a6)

Comment (0)