With a growth rate of 10-11% per year, accounting for 2-5% of the GDP of the entire industry, the chemical industry has made important contributions to economic growth.

Platform industry

According to Oxford Economics' global analysis, the chemical industry is the fifth largest manufacturing sector globally, in terms of direct annual contribution to GDP, accounting for 8.3% of the total economic value of the global manufacturing industry. That means the role of the chemical industry in the economy has been affirmed.

|

| The chemical industry is a fundamental industry, accounting for 2-5% of the GDP of the entire industry. |

Meanwhile, according to the Department of Chemicals ( Ministry of Industry and Trade ), chemicals are present in most areas of social life, the chemical industry has created many products, playing an increasingly important role in the industrial and economic development of each country. In particular, as life becomes more and more developed and civilized, the role and position of the chemical industry becomes increasingly important.

In Vietnam, the chemical industry was formed and developed since the 50s of the last century, starting with fertilizer and consumer chemical factories in the North with the help of the Soviet Union and China with the aim of providing fertilizer and some chemicals for consumption. Through the stages of development, the chemical industry has made strong progress with its appearance changing significantly compared to the beginning.

Especially since the Law on Chemicals 2007, the Vietnamese chemical industry has increasingly developed and affirmed its important role, gradually modernizing, mastering technology, proactively producing raw materials and products for the domestic manufacturing industry, and moving towards export...

According to Ms. Nguyen Thi Theu - Chemical Industry Development Department (Chemical Department - Ministry of Industry and Trade), Vietnam's chemical industry is known for 10 sub-sectors, including: Fertilizers; plant protection chemicals; pharmaceutical chemicals; petrochemicals; basic chemicals; rubber products; electrochemical products; detergents; paints and printing inks; industrial gases.

In which, the petrochemical sub-sector with products for many developing industries such as PE, PP, PVC, PS plastics... for the plastic and packaging industry and synthetic fibers such as PET, PA for the textile industry, LAB raw materials for detergent production.

The basic chemical industry is the main raw material for many production fields, promoting many other production fields such as fertilizers, paper, plastics, glass, ore processing, metallurgy, petrochemicals, tanning, textile dyeing, batteries, soaps and detergents, water treatment chemicals, food, pharmaceuticals, pesticides, pigment and paint additives, concrete additives...

The electrochemical sub-sector includes the production of batteries and chemical accumulators; the industrial gas sub-sector, rare gases, special gases O2, N2, CO2... used in the metal welding and cutting industry, shipbuilding and repair industry, frozen food processing industry, pharmaceutical industry, electronics industry, steel industry, gas pipeline cleaning... and some applied technology industries such as rubber vulcanization, special steel tempering, glass production, fertilizer..., in medicine ...

While the rubber products sub-sector produces rubber tires, technical rubber, and special rubber; the cosmetics sub-sector produces soap, detergents, cleaning agents, cosmetics, etc.; the industrial paint sub-sector not only contributes to beauty but also has the effect of protecting and increasing the life of products and works. The industries, infrastructure construction, and real estate have also become diverse and have conditions for development, so the demand for paint is increasing and diversifying...

According to Ms. Nguyen Thi Theu, the chemical industry is a foundation industry, accounting for 2-5% of the GDP of the entire industry with a growth rate of 10-11%/year. The labor force in the chemical industry accounts for 2.7 million people, accounting for 10% of the labor force of the entire industry. Labor productivity of the chemical industry accounts for 1.36 times the average labor productivity of the entire industry.

In particular, implementing the Party's policies and guidelines at the 13th National Congress, chemicals are identified as one of the fundamental industries, and developing the chemical industry is one of the key tasks and solutions to promote the country's socio-economic development.

Thus, it can be affirmed that chemicals play an important role, being the “foundation” for other industries. As Mr. Pham Huy Nam Son, Deputy Director of the Department of Chemicals (Ministry of Industry and Trade) said: “ If there were no chemical industry, there would be no industry at all”.

…but not yet fully exploited

According to statistics, Vietnam currently has about 2,000 enterprises operating in the chemical sector, distributed to 10 sub-sectors and across the 3 regions of North - Central - South. Vietnam has initially formed a chemical industry with a relatively complete structure, including main production sectors such as fertilizers: Nitrogen fertilizer, phosphate fertilizer, DAP, NPK; basic chemicals such as H2SO4, caustic soda, HCl; petrochemical products such as fibers, PS, PP plastics; rubber products, consumer chemicals, etc.

In particular, new projects in the chemical sector, especially petrochemical, pharmaceutical and basic chemical projects, have contributed to diversifying the types of domestically produced chemical products. However, high-tech products have not yet been produced domestically, and input materials are still heavily dependent on imports.

In the fertilizer industry, except for potassium and SA fertilizers that must be imported due to the lack of raw material advantages in the country, the Vietnamese fertilizer industry has provided enough for domestic needs for most types of fertilizers. Processed phosphate and NPK fertilizer products have been partially exported. Nitrogen fertilizer alone currently has an oversupply of about 500,000 tons/year. The pesticide industry has basically met domestic demand, however, most of the facilities are processing and blending facilities; 90% of raw materials for pesticide production must be imported.

Regarding petrochemicals, Vietnam is currently only able to produce PVC, PP, DOP plasticizers, and synthetic fibers from imported intermediate materials. In recent years, the petrochemical industry has received strong investment attention with many large projects such as Nghi Son, Long Son, Hyosung... However, it is estimated that when these projects are put into operation, Vietnam will still have to import about 2 million tons/year of petrochemical products.

In the field of rubber product manufacturing, many multinational enterprises have invested in tire production in Vietnam, making our country a country with a surplus in tire exports. Currently, there are still other investors implementing tire production projects in Vietnam. However, the technical rubber sector has not received much investment.

Vietnam's industrial gases have produced common industrial gases such as oxygen, nitrogen, acetylene, argon, compressed air, N2O, hydrogen and mixed gases... and basically met the domestic demand for these gases.

Regarding paints and inks, the types of domestically produced products are quite diverse but high-end paint lines have not yet been produced. Raw materials for plastic production, pigments, and additives must mainly be imported. Regarding electrochemical products, in general, Vietnam has only met the common needs of the domestic market. Specifically: Common batteries (types R6 and R20) meet about 90% of the demand. Accumulators have met about 70% of the demand for car batteries and 50-60% of the demand for motorbike batteries. Specialized, high-tech products have not yet been produced...

According to statistics from the Department of Chemicals, from 2015 to present, the chemical trade balance has always been negative, which reflects the reality that Vietnam's demand for chemicals is increasing rapidly to serve production and promote economic growth while domestic production capacity has not caught up with demand. That also reflects the development of the domestic chemical industry and the role of the chemical industry will be increasingly important to promote the growth of the industry, increase the export of products with economic value...

With a stable political background, a fairly good economic growth, and accumulated savings, the chemical industry has maintained a fairly high growth rate over the years; labor productivity is 1.36 times higher than the average labor productivity of the entire industry due to a fairly high level of automation. In addition, the Vietnamese economy is highly open, participating deeply in economic agreements and organizations... which has opened up opportunities for the development of the Vietnamese chemical industry.

However, according to Ms. Nguyen Thi Theu - Chemical Industry Development Department (Department of Chemicals) and economic experts, Vietnam's chemical industry has been developing below its potential in recent times.

In fact, statistics also show that, in general, although the Vietnamese chemical industry has developed and applied many achievements, there are many projects and production lines applying modern technologies, equipment, management and operation software, the vast majority of factories are still small-scale, the technology is not really high, the rate of unskilled labor is still quite high, some places have not mastered the technology, and depend on copyright owners. The reason is that science and technology are not high, there is no source technology, lack of capital, modern factories with high and modern technology require huge costs that the private sector can hardly invest in; management level, policy mechanisms... and some shortcomings and negative aspects have not been completely resolved.

Developing a sustainable chemical industry

To promote the development of the chemical industry in a more sustainable and environmentally friendly direction, in Resolution No. 124/NQ-CP dated September 3, 2020, the Government assigned the Ministry of Industry and Trade to preside over the development of the Strategy for the development of Vietnam's chemical industry to 2030, with a vision to 2040. The Strategy was approved by the Prime Minister in Decision No. 726/QD-TTg dated June 16, 2022.

|

| Striving for an average growth rate of 10-11%/year in the chemical industry - Photo: QN |

The strategy for developing Vietnam's chemical industry to 2030, with a vision to 2040, has set out the direction for developing Vietnam's chemical industry towards becoming an important, modern, fundamental industry with a relatively complete industry structure, including 10 sub-sectors, focusing on the development strategy of a number of key sub-sectors: Basic chemicals, petrochemicals, technical rubber, pharmaceutical chemicals and fertilizers.

Reorganize existing production facilities in a concentrated and large-scale direction. Maintain and develop factories with advanced technology. Minimize the establishment of new ones and gradually eliminate small-scale production facilities that use outdated technology, have low resource efficiency, poor product quality, and cause environmental pollution...

Specific goals, by 2030: Building a chemical industry with a relatively complete structure, including production of production materials and consumer goods, serving many other industries; increasingly meeting domestic demand and boosting exports; focusing on prioritizing the development of key sub-sectors such as basic chemicals, petrochemicals, technical rubber, pharmaceutical chemicals, and fertilizers.

At the same time, form a value chain, deeply participate in the production network of Vietnam's and the region's industry. Use resources rationally and economically; apply modern technology, digital economy and digital transformation to increase added value, enhance the competitiveness of the industry, promote capital accumulation of economic groups operating in the chemical sector; reasonably distribute production forces by industry and territory, form and effectively promote concentrated industrial zones and clusters, and large-scale chemical production complexes.

By 2040, Vietnam's chemical industry will be developed with most sub-sectors having advanced technology, product quality meeting international standards, deeply participating in the global value chain, using energy economically and effectively, competing equally in international integration; professional, disciplined and highly productive workforce; initially proactive in the stages of research, design, manufacturing, mastering the technology to produce a number of high-quality products; promoting internal resources, contributing to the development of an independent and self-reliant Vietnamese economy.

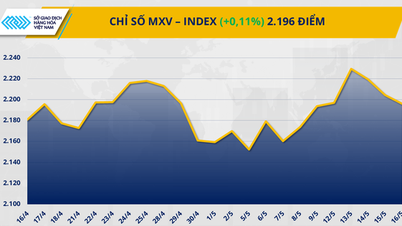

It is expected that Vietnam's chemical industry will strive for an average growth rate of 10-11% per year and the proportion of the chemical industry compared to the entire industry will reach about 4-5% by 2030; by 2040, the growth rate of the chemical industry will reach an average of 7-8% per year and the proportion of the chemical industry compared to the entire industry will maintain about 4-5%.

By 2040, meet part of the domestic demand for basic organic chemicals, specialty paints, high-tech batteries and accumulators; increase the ability to meet the average domestic demand for petrochemical products to 60%, plant protection active ingredients to 50%, basic chemicals to 80%, technical rubber to 50%, and batteries to 80%; strive for an average export growth rate of 9-11%/year in the 2021-2030 period, and an average growth rate of 7.5-9%/year in the 2030-2040 period.

To achieve the above objectives, the groups of solutions are focused on implementing in the Strategy, including general and fundamental groups of solutions: Innovating policy mechanisms, promoting administrative procedure reform to meet the development requirements of the chemical industry; improving investment and production efficiency at enterprises; improving the efficiency of cooperation and linkage; effective trade policy and market development; developing human resources for the chemical industry; developing science and technology; focusing on investing in technical infrastructure works, having measures on general environmental management and protection and for the chemical industry; having appropriate financial measures and policies.

In addition to the group of general, basic solutions, the Strategy also offers breakthrough solutions such as: Investing, attracting, and calling for investment in building concentrated chemical industrial parks and logistics centers.

The strategy for the development of Vietnam's chemical industry to 2030, with a vision to 2040, clearly states the viewpoint: Harmoniously combining breadth and depth of development, rapid and sustainable development of the chemical industry, applying modern, environmentally friendly technology, adapting to climate change, effectively using natural resources, aiming for green growth and circular economy; applying digital transformation and digital technology to increase the efficiency of production and business activities in the chemical sector... |

Lesson 2: It is necessary to amend the Law on Chemicals to promote the potential of the field.

Source: https://congthuong.vn/sua-doi-luat-hoa-chat-dua-nganh-cong-nghiep-hoa-chat-viet-nam-phat-trien-xung-tam-bai-1-357953.html

![[Photo] Ready for the top competitions of Vietnamese table tennis](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/18/9c547c497c5a4ade8f98c8e7d44f5a41)

![[Photo] Party and State leaders attend the special art program "You are Ho Chi Minh"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/18/6895913f94fd4c51aa4564ab14c3f250)

![[Photo] Many young people patiently lined up under the hot sun to receive a special supplement from Nhan Dan Newspaper.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/18/6f19d322f9364f0ebb6fbfe9377842d3)

Comment (0)