After graduating from Hanoi University of Science and Technology, Phung Duc Canh (32 years old) decided to return to his hometown Hai Phong to find a job instead of staying in the capital like many of his friends.

"Aiming" at LG Electronics Vietnam Co., Ltd. to recruit for the position of production engineer, Mr. Canh sent his application and was accepted.

His job is to be in charge of the television production line, manage the machinery, maintain and service the equipment to ensure smooth operation. The job has a starting salary of 7.5 million VND/month.

Working in his field of study, he always tries his best to explore and learn new things.

Mr. Canh and his colleagues create robots to help increase productivity and reduce costs for businesses (photo: NVCC).

"At first, when experts came to the factory to install the production line, I actively followed them to learn, relearning from the smallest things like how to screw. Everything accumulated gradually, until now, we can control robots, further to build robots to help improve labor productivity," Mr. Canh shared.

Previously, the factory only had 5-6 production lines, but now it has grown to 80 lines. The automation process at the factory is extremely strong. 2,000 robotic arms serving production are always present in the company.

Being in charge of innovation and creativity, he always wants to contribute to increase productivity and output. All of his and his colleagues' initiatives in the past have originated from the hardships that workers are facing.

Realizing that cleaning toilets is very hard work, Mr. Canh "worked hard" to research and design a machine that can replace humans in this position.

Despite many failed attempts, he remained persistent and continued to research and modify the automatic toilet cleaning machine.

Working at a unit that produces household appliances such as washing machines, televisions, refrigerators, etc. or entertainment screens for many luxury cars, Mr. Canh noticed that many workers were having to do quite strenuous and difficult work. To reduce that pressure, Mr. Canh and his colleagues have researched and improved more effective technology.

Canh and his colleagues have researched and improved technology to be more effective (photo: NVCC).

Mr. Canh shared that he observed that the company had to assign two workers to work on the car entertainment screen stickers. This is a job that requires meticulousness and high concentration, otherwise the stickers will easily deviate from the frame. In fact, every day, the workers have to stick traceability stickers on thousands of screens, which is very hard.

In 2020, he and his colleagues researched a machine that could do this job instead of humans. After working day and night, with contributions and criticism to perfect the group, an automatic labeling robot was born.

In order for the machine to operate effectively and with absolute precision in labeling traceability, Mr. Canh's team experienced many failures and had to continue to edit and perfect the device for 3 months.

"The labeling machine using a robotic arm costs about 300-400 million VND to design. But like any machine, it cannot be assembled and operated immediately but must be repaired many times," the 9x engineer shared.

Mr. Phung Duc Canh.

The robot arm that stamps labels has now replaced the work of three workers who work tirelessly all day. The machine's productivity is twice that of humans.

Normally, workers can paste 300 products/hour, but thanks to this device, productivity increased to 600 products/hour. Currently, the robot arm is applied to 4 production lines.

This device can paste accurately and quickly, matching information for future warranty retrieval. From there, ensuring the partner's requirements before exporting to the US and Europe. Currently, the robot has been applied to the production line of Mercedes and Toyota car screens.

After the success of the automatic labeling robot arm, Mr. Canh's team also researched and designed a door tape machine for the horizontal drum washing machine production line.

These automatic touch testing machines for car screen assembly lines, automatic labeling machines, tape pasting machines... have brought the company more than 10 billion VND in profit.

Nowadays, the application of technology and automation is taking place quite strongly in enterprises. Discussing concerns about whether machines and robots will "steal" workers' jobs, Mr. Canh affirmed that workers will not lose their jobs, but will be arranged by the company to other positions that reduce hardship and fatigue.

He said that the company is currently expanding and the employer needs to recruit more workers.

"Robots are just like humans who need to "bathe", they need to be cleaned, maintained and need operators. Robots cannot completely replace human work," Mr. Canh affirmed.

Commenting that "opportunities are now equally distributed to everyone", the male engineer recommended that each worker needs to improve their skills and expertise to be more productive and work more effectively.

Source link

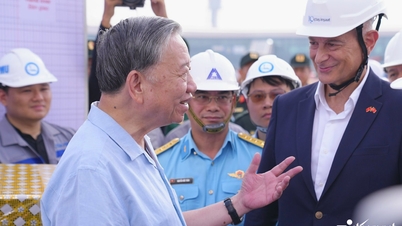

![[Photo] General Secretary To Lam visits Long Thanh International Airport Project](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/13/1763008564398_vna-potal-tong-bi-thu-to-lam-tham-du-an-cang-hang-khong-quoc-te-long-thanh-8404600-1261-jpg.webp)

![Dong Nai OCOP transition: [Article 3] Linking tourism with OCOP product consumption](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/11/10/1762739199309_1324-2740-7_n-162543_981.jpeg)

Comment (0)