On June 19, a workshop on "Sustainable and economically efficient road solutions" was held in Ho Chi Minh City. At the workshop, scientists, representatives of management agencies, and contractors all agreed that the application of sustainable solutions in road construction and maintenance is an inevitable trend that needs to be replicated in many road projects in Vietnam.

Most recently, at the COP26 Conference, Vietnam announced that it would achieve net zero emissions by 2050. The Prime Minister also issued Decision No. 876 dated July 22, 2022 on green energy conversion, reducing carbon and methane emissions in the transport sector.

Below is a summary of the outstanding technical solutions presented by the speakers at the conference.

Accelerated Adhesion Emulsion (EAP): Sustainable Solution for Road Construction in Vietnam

Overview of the Workshop "Sustainable and Economically Efficient Road Solutions"

Sharing at the workshop, Associate Professor, Dr. Nguyen Quang Phuc, Department of Roads, Faculty of Construction, University of Transport (UT-VT) said that EAP asphalt emulsion is a type of emulsion specially designed as an adhesive layer, with good adhesion to the surface of the base layer and quick drying, helping to be flexible during construction.

There are many large emulsion manufacturers in the world, producing emulsion products with different names. EAP emulsion is applied in many countries in the world for road construction such as: USA, Australia, New Zealand, Thailand...

According to the assessment of the US National Center for Asphalt Technology (NCAT), using EAP penetrating asphalt emulsion causes less environmental pollution due to low volatile content, less risk of fire and explosion compared to liquid asphalt, convenient for road construction because it does not require heating, and can be watered when the surface is saturated with moisture and the surface is dry.

This is a very favorable factor for road construction in Vietnam when our country has a lot of rain.

In Vietnam, EAP permeable emulsion is known and used through the EcoPrime ® product line developed and supplied by ADCo company, meeting the technical specifications of TCCS 27:2019/TCDBVN as a permeable layer for road surface structures.

Assoc.Prof.Dr.Nguyen Quang Phuc speaking at the conference

Research results of Dr. Do Vuong Vinh, Department of Roads, Faculty of Construction, University of Transport at the EcoPrime ® permeable emulsion construction project on National Highway 26 Khanh Hoa show that EcoPrime ® asphalt emulsion penetrates deeply and separates quickly after 8 hours of watering on the crushed stone aggregate base layer in night conditions with an ambient temperature of about 23 degrees Celsius

After 5 hours of watering, trucks can pass through without the adhesive layer peeling off. This is a big advantage when using adhesive asphalt emulsion in the conditions of many road projects in Vietnam that are both under construction and in operation, helping to speed up progress and be flexible in construction.

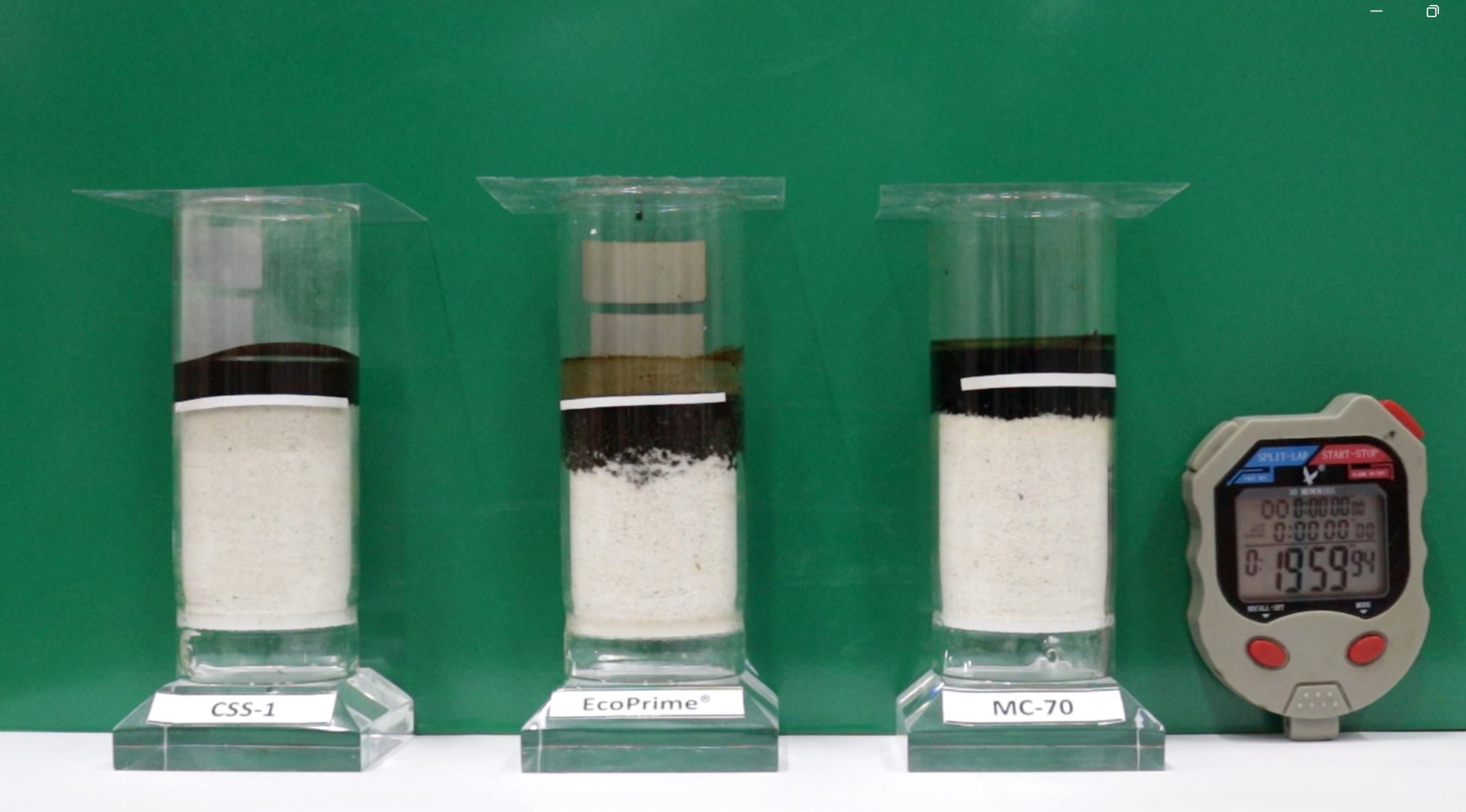

Dr. Vinh also shared information when comparing the permeable emulsion with other products such as MC-70 and CSS-1 separating emulsion at the QL10 - Thai Binh expansion project, also found the advantage is that after 4 hours (daytime, ambient temperature about 30 degrees Celsius) the traffic did not peel off, while CSS-1 emulsion peeled off and MC70 did not separate.

Comparative permeability test between CSS-1, EcoPrime® and MC-70.

Preventive Pavement Maintenance: Microsurfacing Technology Application in Ho Chi Minh City

At the workshop, Mr. Le Ngoc Hung - Head of Product Development, Asphalt Supply Company Limited (ADCo Company), introduced Microsurfacing technology in preventive maintenance of road surfaces, applied when the road surface structure is still stable, but the surface begins to show oxidation and slight peeling.

This solution helps improve waterproofing, skid resistance, protect the underlying structure, prolong the life of the road surface, improve traffic safety and optimize costs, while also being quickly constructed and open to traffic after about 1-1.5 hours during the day and after about 3-4 hours at night.

Widely used around the world, Microsurfacing has proven its effectiveness in many transportation projects, especially in Vietnam, such as the pilot project on National Highway 21B Nam Dinh applied since 2017, the road surface quality remains stable.

Speaking at the workshop, Mr. Luong Nhat Binh, Department of Infrastructure Management 4, Ho Chi Minh City Road Traffic Infrastructure Management Center said that the Ho Chi Minh City Department of Transport is managing 850 routes with 1,365 km of bridges and roads, with a total surface area of 16.5 million square meters of asphalt concrete roads and bridges.

The maintenance volume is very large. To ensure the effectiveness of maintenance, Ho Chi Minh City has applied many methods such as: Scraping, asphalt concrete pavement, scraping, road surface regeneration, treatment, deep foundation, road surface, replacing new structural layers.

Regarding materials, the Department has tested many new materials such as carboncor and densiphalt. However, these materials are not suitable for road maintenance in Ho Chi Minh City.

Vo Tran Chi Street after testing Microsurfacing.

In order to find a new and more effective solution, Ho Chi Minh City has piloted Microsurfacing technology to maintain Vo Tran Chi Street in order to find a proactive, economical, effective and environmentally friendly maintenance solution in the actual conditions of Ho Chi Minh City.

On the other hand, the project also tests the performance of the Microsurfacing coating under conditions of high traffic routes with many heavy trucks circulating while the road surface of this route is due for maintenance and repair.

The pilot results show that, compared with scraping, the new 5cm hot asphalt concrete carpet with Microsurfacing technology: Maintenance costs reduced by 66%, energy consumption reduced by 91%, greenhouse gas emissions reduced by 91%, and aggregate savings reduced by 89%.

After one month of construction, the technical criteria on the route are still guaranteed despite the high traffic density of this route. The project will continue to be monitored and evaluated to have a basis for submitting to the Ho Chi Minh City Department of Transport for widespread application on the city's routes.

Cold Recycling Technology: A Road Rehabilitation Method in Vietnam

At the workshop, Mr. Christophe Duboscq, Head of Regional Technical Department - TIPCO-COLAS Group introduced cold recycling technology as an advanced road surface restoration method applied in the world, including Vietnam, to solve the problem of road surface damage due to climate and traffic.

Recycling technologies include: Hot recycling (using a mixture of asphalt concrete and scraping materials) and cold recycling (including on-site and at-station recycling). The advantage of these methods is that the material is mixed with a scraping machine or at the station with a specialized emulsion.

The result is that all existing scraping materials can be reused, without incurring the cost of importing new materials.

Low energy consumption, reducing transportation costs. Cost savings compared to the traditional method of scraping, dumping and covering with new asphalt concrete. Can be reopened to traffic immediately after compaction.

Mr. Christophe Duboscq speaking at the conference

Results from cold recycling technology compared to traditional methods: Energy consumption reduced by 44%. Greenhouse gas emissions reduced by 58%. Aggregate savings of 68%.

Cold on-site recycling technology has been applied to the construction of National Highway 13 in Binh Phuoc since 2020. Mr. Vo Phi Bao, Deputy General Director - Binh Phuoc Infrastructure Construction Investment Joint Stock Company, said that the project to repair and upgrade National Highway 13 with a length of 32km applies cold recycling technology.

The project was completed with all technical criteria met. After the exploitation process, the road surface remained stable and ensured quality. Saving costs and construction time compared to traditional methods.

From this success, Binh Phuoc should plan to expand cold recycling technology to other sections of the province.

In addition, Mr. Bao also shared that he will continue to apply new technologies and new materials with ADCo in the project such as: Elastic Modular Asphalt Concrete with additional fatigue resistance EME and Oil-resistant Polymer Asphalt at intersections with slow traffic speeds.

"Cold recycling technology brings many economic and environmental benefits, suitable for the actual conditions in Vietnam. Applying this technology not only helps reduce maintenance and road surface improvement costs but also contributes to environmental protection, improving the efficiency of resource and energy use," said Mr. Vo Phi Bao.

Cold recycling technology at National Highway 13, Binh Phuoc.

Another cold recycling technology applied on National Highway 51 Dong Nai is cold recycling at the station.

Dr. Nguyen Ngoc Lan, Head of the Department of Construction Materials - Faculty of Construction Engineering, University of Transport, said that in Vietnam, standards for cold recycling technology are gradually being completed.

This technology allows 100% reuse of recycled materials (RAP), while controlling the quality of mixing and storing materials more efficiently.

Cold Station Recycling (CCPR) technology is an effective method for asphalt pavement rehabilitation. This is an advanced technique that has been widely applied in many countries such as the US, Europe, and China, but is still new in Vietnam.

The trial construction process on National Highway 51 includes the steps of scraping the road surface, cleaning and watering with CSS-1h emulsion at a rate of 0.8 l/m2. After that, the materials are mixed at the mixing station and transported for construction and spreading on the road surface.

The technical properties of the cold recycled mix were evaluated based on Marshall stability, rebound, and modulus of elasticity. The results showed that the cold recycled mix met the required limits according to AASHTO MP31-22.

Environmentally, with the ability to reduce CO2-eq emissions and energy consumption compared to traditional technologies such as hot mix asphalt (HMA). CCPR has the potential to reduce energy consumption by up to 51.6%, while hot mix recycled asphalt only reduces it by 14.2%.

Cold on-site recycling technology is a sustainable and cost-effective solution for road maintenance and repair. The application of this technology in Vietnam requires the development of standards for design, construction and acceptance to ensure quality and long-term efficiency.

Dr. Nguyen Ngoc Lan speaks at the conference

Dr. Lan added, "The 2023 research project of the Ministry of Transport proposes to develop basic standards for the design, construction and acceptance of cold recycled asphalt concrete layers at mobile mixing stations, promoting the application of this technology in our country."

Cold recycling technology at the station not only saves costs but is also environmentally friendly, suitable for the needs of maintaining and upgrading the road system in Vietnam.

Continued research and improvement of technical standards will contribute to improving the effectiveness of applying this technology in practice.

Cold Asphalt Concrete: Effective Solution for Road Surface Repair

Cold asphalt technology, with ADCo's Cold Patch ® product, is an effective and sustainable solution for pavement maintenance and repair.

This is a ready-mixed, bagged asphalt concrete designed for use in pavement maintenance and repair. Cold Patch ® has outstanding advantages such as ease of use, long storage life, quick application and allows for immediate traffic opening after application.

Cold Patch®

Mr. Hoang Dinh Kien, Head of Technical Department, ADCo Company said, Cold Patch ® is highly appreciated for its safety, economy and flexibility. This is an environmentally friendly product, with high durability and good water resistance. Cold Patch ® can be applied on many different types of road surfaces such as asphalt concrete or cement concrete.

Cold Patch ® can be used to patch potholes, fill trenches and repair small areas. The application process is simple and quick, consisting of cleaning the surface, watering with emulsion if required, spreading Cold Patch ®, grading and compacting. Once these steps are completed, the road can be opened to traffic immediately.

"Cold Patch ® has been used in many projects in Vietnam, including pothole repair on the Noi Bai - Lao Cai highway, filling technical trenches in industrial zones and compensation for road subsidence at the bridgehead on the Hanoi - Thai Nguyen highway. These projects have demonstrated the effectiveness and sustainability of Cold Patch ® technology in real conditions in Vietnam," said Mr. Hoang Dinh Kien.

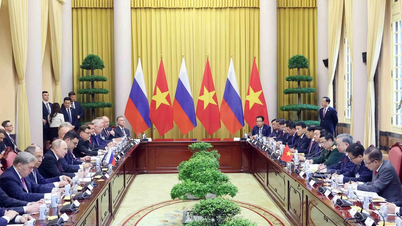

Representatives of the Ministry of Transport, Vietnam Road Administration, Road Management Area III, along with representatives of leaders of provincial Departments of Transport, Project Management Boards under the Road Administration, local Departments of Transport, consulting and supervision companies, contractors, and leading professors and doctors of the Faculty of Construction, Bridges and Roads at the University of Transport, and experts discussed research and application of new technologies, structures, and environmentally friendly materials... to help the transport industry develop sustainably.

Along with that, through the workshop, Vietnamese and international managers and businesses shared and exchanged experiences on road solutions and new technologies that are sustainable and increase the life of roads.

Source: https://www.baogiaothong.vn/hieu-qua-ap-dung-cac-giai-phap-ben-vung-thi-cong-bao-tri-duong-bo-192240630160250124.htm

![[Photo] National Assembly Chairman Tran Thanh Man chairs the meeting of the Subcommittee on Documents of the First National Assembly Party Congress](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/72b19a73d94a4affab411fd8c87f4f8d)

![[Photo] General Secretary concludes visit to Azerbaijan, departs for visit to Russian Federation](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/7a135ad280314b66917ad278ce0e26fa)

![[Photo] President Luong Cuong presents the decision to appoint Deputy Head of the Office of the President](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/501f8ee192f3476ab9f7579c57b423ad)

![[Photo] General Secretary To Lam receives leaders of typical Azerbaijani businesses](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/998af6f177a044b4be0bfbc4858c7fd9)

![[Photo] Prime Minister Pham Minh Chinh talks on the phone with Singaporean Prime Minister Lawrence Wong](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/8/e2eab082d9bc4fc4a360b28fa0ab94de)

Comment (0)