Tan Quang Cement Factory campus is planted with trees to protect the environment.

Investment development associated with environmental protection

Recognizing the importance of the environment for long-term development, Tan Quang Cement Joint Stock Company - VVMI has actively implemented many synchronous solutions to control and minimize environmental impacts from production activities. Every year, the company spends more than 2 billion VND on environmental protection, from investing in dust and wastewater treatment systems to greening measures in production areas.

The National Assembly delegation of the province supervises environmental protection work at Tan Quang cement factory.

At the environmental protection monitoring session of the Provincial National Assembly Delegation on March 19, 2025, Mr. Le Danh Thang, Director of Tan Quang Cement Joint Stock Company - VVMI, said that one of the important solutions implemented by the company is to invest in an advanced dust treatment system. Up to now, the company has equipped 2 electrostatic dust collectors and 35 fabric bag dust collectors, ensuring the ability to filter 99% of the dust generated during the production process. In addition, the company also installed 46 fabric bag dust collectors at different stages to minimize the amount of dust released into the environment.

The company also pays special attention to emission control. To ensure that emissions are treated to standards before being discharged into the environment, the company has completed the installation of an automatic, continuous emission monitoring system with surveillance cameras, directly transmitting data to the Department of Natural Resources and Environment of Tuyen Quang. This system helps authorities closely monitor the company's emission levels, ensuring that production activities always comply with environmental protection regulations.

The company's cement production line.

Wastewater and solid waste management

In addition to controlling dust and emissions, the company also focuses on wastewater treatment and solid waste management. To ensure that wastewater discharged into the environment meets permitted standards, the company has invested in a centralized wastewater treatment system and built a two-compartment settling pond to treat rainwater before discharging it into the environment. The company also collects and treats domestic and industrial waste, and builds a hazardous waste storage facility to strictly manage waste generated during the production process.

Mr. Le Danh Thang added that one of the difficulties the company faces in environmental protection is finding a unit to handle common industrial solid waste. Currently, hiring a unit to handle this type of waste still has many problems, requiring the company to find suitable solutions to ensure that the waste is handled according to regulations.

Company staff check product quality.

In addition to focusing on waste treatment, the company also focuses on improving the landscape, creating a green, clean and beautiful working environment. One of the solutions implemented is to plant trees around the production area, helping to limit dust dispersion and create a fresher working space. The company also organizes water trucks to spray dust on internal roads every day, helping to minimize the amount of dust generated by the transportation of raw materials. Regular industrial cleaning is also focused on, ensuring a clean and safe working environment for workers.

In the coming time, the company will continue to invest in upgrading environmental protection works, while promoting the application of modern technology in production to minimize negative impacts on the environment. At the same time, the company will also closely coordinate with the authorities to remove existing difficulties, especially the problem of industrial solid waste treatment.

By investing in upgrading technology, optimizing management processes, saving costs and improving product quality, the Company continues to affirm its position in the market. At the same time, strictly implementing regulations on labor safety, environmental protection, and committing to ensuring jobs and stable income for employees, is the foundation for the Company to develop sustainably, contributing positively to the socio-economic development of the locality. In 2025, the Company strives for a sales output of 890,000 tons, revenue of more than 800 billion VND and a contribution to the State budget of over 46 billion VND.

Source: https://baotuyenquang.com.vn/cong-ty-co-phan-xi-mang-tan-quang-vvmi-san-xuat-gan-voi-bao-ve-moi-truong-208904.html

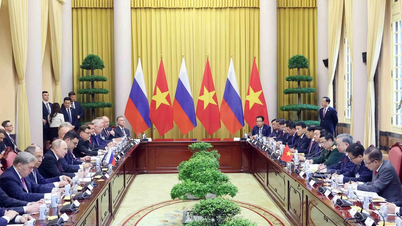

![[Photo] General Secretary concludes visit to Azerbaijan, departs for visit to Russian Federation](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/7a135ad280314b66917ad278ce0e26fa)

![[Photo] General Secretary To Lam receives leaders of typical Azerbaijani businesses](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/998af6f177a044b4be0bfbc4858c7fd9)

![[Photo] Prime Minister Pham Minh Chinh talks on the phone with Singaporean Prime Minister Lawrence Wong](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/8/e2eab082d9bc4fc4a360b28fa0ab94de)

Comment (0)