| The role of trade unions in promoting labor productivity growth Vietnam needs to increase investment in science to improve labor productivity |

Small but agile, active, and approachable is the impression of most people when meeting Ms. Phung Thi Hanh - a worker at Hanoi Shirt Factory - who was honored to speak at the Forum "Improving National Labor Productivity", organized by the Vietnam General Confederation of Labor in late May 2024.

Hanh shared that "stepping foot" into May 10 (short for May 10 Corporation) in 2010, when she was just 18 years old, with the mindset of a young person and a passion for working in the garment industry, she was always cheerful and excited, but also could not help but worry and feel bewildered, because new workers had never been through training.

|

| Ms. Phung Thi Hanh speaks at the Forum "Improving national labor productivity". Photo: VGP |

However, with the help of her seniors, Hanh has become more flexible every day, gaining valuable experience from how to arrange and organize goods in a reasonable and convenient way, to eliminating unnecessary steps in her work. Every day, she tries to complete her work well, while paying attention to learning other steps, which has helped Hanh improve her skills. Thereby, labor productivity has also increased.

“ From completing 200-300 products in the early days, after 5 months I was able to sew 700-800 products/day. Although this result had increased, I was not satisfied and always wondered how to improve my skills further? Higher productivity? To answer my question, I learned how to control my time with the goal of increasing productivity by at least 5% per hour compared to the previous hour. With perseverance and patience, more than a year later, I was the leader in productivity at the unit with 1,400 products/day, reaching 150% compared to colleagues in the same stage , '' Hanh shared.

Not satisfied with the results achieved, Hanh continued to learn other steps to improve her skills, becoming a dispatcher who could do any position in the production line.

After nearly 15 years of working in the profession, Ms. Phung Thi Hanh not only completed her assigned work well but also represented her in the Corporation-level Skilled Worker Competition, the Skilled Worker Competition and the Industry-level Creative Labor Festival organized by the Vietnam Textile and Garment Trade Union.

Hanh could not hide her joy as she confided: “ Each time like that, I eagerly wait, because I can learn many good ways of doing things, new operations from the best workers in the country. With the process of continuous learning and training, up to now, I have always been the most productive and highest-income worker of the enterprise with a salary of 15,000,000 VND/month. For many consecutive years, I have been an excellent worker, an excellent union member, the title of Emulation Fighter and Exemplary Worker ”.

Having achieved many achievements and gained more experience in production, Hanh is always proactive in sharing and instructing her friends and colleagues. What is more enjoyable is that everyone is very excited to follow Hanh's instructions and improve productivity. " I am very happy to have brought a positive spirit to everyone as well as contributed to the overall achievements of the Corporation. That is how I express my love and gratitude to the place where I have worked and been attached to over the years, and to the predecessors who have passed on their skills to me with all the respect and deep gratitude ", Ms. Phung Thi Hanh expressed.

It is known that in order to meet the new requirements in the context of the 4.0 technology revolution, in recent years, Garment Corporation 10 has invested in many modern machines and equipment, thereby shortening production time and improving the competitiveness of the enterprise. Many automatic devices are used effectively such as the hanging conveyor system to increase productivity by 30%, automatic fabric spreading system, automatic cutting machine, programming machine, automatic sewing machine... to increase productivity from 150 - 200%. However, to achieve that result, there is great effort from workers who have proactively learned, responded to and mastered new technology, including Hanh.

Source: https://congthuong.vn/co-cong-nhan-may-va-nhung-sang-kien-de-tang-nang-suat-lao-dong-336684.html

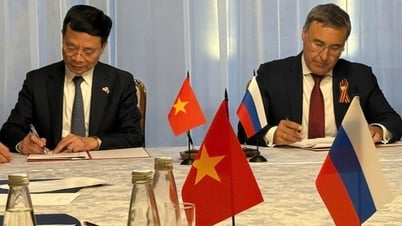

![[Photo] General Secretary To Lam begins official visit to Russia and attends the 80th Anniversary of Victory over Fascism](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/5d2566d7f67d4a1e9b88bc677831ec9d)

Comment (0)