Promoting the qualities of Uncle Ho's soldiers, he always strive to do good business with new ways , helping families and many local people change their lives.

Following in the footsteps of our ancestors

Leaving the army in 1990, Mr. Tuan returned to his hometown with the worries of daily life. To earn an income to support his family and himself, he started a business from the traditional broom making profession passed down from his grandparents and parents.

Mr. Nguyen Nhat Tuan has been involved in the traditional broom making profession for more than 30 years. Photo: TN

Mr. Tuan confided: "My hometown Chiem Son village was famous for its traditional broom making craft that is hundreds of years old. Therefore, when I returned to my hometown, my father taught me and I have been attached to the craft until now.

Although I have experienced many ups and downs, I always love the assets that my ancestors left me and strive to develop them so that the traditional profession does not fade away."

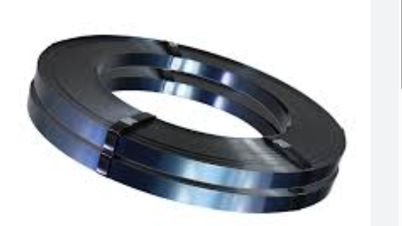

According to Mr. Tuan, there is only one crop of brooms per year, starting from December to February of the following lunar year. To have a year-round source of broom materials, he has to buy dozens of tons of fresh brooms, dry them, and store them.

Currently, Mr. Tuan creates jobs for more than 20 workers, mainly wives and children of veterans, the elderly, people with disabilities... Photo: TN

Previously, he purchased cotton from mountainous districts of Quang Nam, but now the supply is scarce so he has to import more from Laos.

Fresh cotton is dried, separated into bundles, wrapped around the neck, then tied tightly to the broom handle and woven into the body of the broom.

Although the job is simple, to have a durable, strong and beautiful broom, it must go through many stages, requiring the maker to have skillful and diligent hands.

Fresh cotton is dried, separated into bundles, wrapped around the neck and braided into brooms. Photo: TN

Mr. Tuan said: "Bringing the broom neck is the most difficult step, deciding the quality of the product. If the person who ties the broom is not skillful, and does not have enough strength to stretch the string, the bundle will not be even, the broom will be ugly and will break easily, and will be damaged quickly. Therefore, this step is only for experienced young men and women."

From the times he cycled around the provinces selling brooms, Mr. Tuan grasped the needs and tastes of consumers and from there boldly innovated production, invested in equipment for sustainable development according to market trends.

The broom braiding process requires the craftsman to be skillful and meticulous so that the broom spreads evenly and beautifully. Photo: TN

Besides the traditional main product of rattan brooms, he also produces many new types of brooms such as: bamboo-handled brooms, brooms wrapped with fishing line, steel wire, plastic box brooms... The price ranges from 20,000-30,000 VND/broom.

Provincial 3-star OCOP product

To maintain and develop the brand, in 2019, Mr. Tuan established Nhat Tuan Broom Agricultural and Commercial Cooperative, consisting of 20 members associated with villagers and production facilities in the village.

On average, Mr. Tuan's facility produces about 2,000 brooms of various types every day. Photo: TN

He diligently brought the traditional brooms of Chiem Son village to participate in fairs to display and introduce products inside and outside the province to learn production experience and approach the consumer market.

In 2020, Nhat Tuan broom products were recognized as meeting the 3-star OCOP standard at the provincial level. On average, the facility produces about 2,000 brooms of various types per day, exported to many provinces and cities in the country with many distributors.

Thanks to that, Mr. Tuan created jobs for more than 20 workers, mainly wives and children of war veterans, the elderly, disadvantaged people in difficult circumstances, and disabled people in the village with an average income of 3-6 million VND/person/month.

Mr. Tuan will continue to make efforts to promote the development of traditional crafts, bringing the Chiem Son broom brand further. Photo: TN

Although the income from making brooms is not much, it is more stable than farming, contributing to poverty reduction in the locality, increasing income and improving the lives of rural people.

Ms. Phan Thi Linh (65 years old) - a worker at Mr. Tuan's workshop shared: "Thanks to Mr. Tuan's support in doing light work such as stripping cotton and tying bamboo, my family's life has been less difficult for many years. If it's not the rice harvest season, I make brooms from 7am to 5pm every day. I work based on output so I'm not constrained. It's close to home, so rain or shine, I have work to earn income."

From a small-scale handicraft production household, Mr. Tuan's family has now become the largest handicraft broom production facility in the region. Mr. Tuan confided: "Previously, the cooperative used to cooperate with businesses to export brooms. But since the Covid-19 pandemic, the consumption market has only been concentrated domestically, and output has decreased significantly.

However, I am still continuing to invest in improving designs and diversifying products to meet new market needs, creating more jobs for local workers and making efforts to bring the Chiem Son broom brand further."

Source

![[Photo] Prime Minister Pham Minh Chinh chairs conference on anti-smuggling, trade fraud, and counterfeit goods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/14/6cd67667e99e4248b7d4f587fd21e37c)

![[Photo] Exhibition "The South forever remembers His grace"](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/14/76916f6645ea47428f530edd4146f70f)

Comment (0)