According to MacRumors , this will help Apple lay the groundwork for its ultimate goal of bringing microLED display technology to the iPhone. Sources say that Apple has spent at least $1 billion on microLED display research and development over the past decade. When production begins, Apple will perform the important mass transfer step itself, which involves placing at least tens of thousands of tiny microLED chips on the panel.

Apple is looking for ways to reduce its dependence on Samsung

Apple plans to produce the tiny microLED chips directly on wafers, the report said, and is partnering with ams-Osram for the microLED components, while LG Display will produce the panels and TSMC will produce the 12-inch wafers. The process is said to take place at Apple's secretive R&D facilities in Longtan District, Taoyuan City, northern Taiwan.

Apple has R&D teams working on displays in the US, Taiwan and Japan. The team is said to have designed not only the driver integrated circuits for microLED displays but also some of the manufacturing equipment to better control the mass production process, allowing the company to apply the new display technology to products that typically use OLED panels supplied by Samsung and other manufacturers.

Despite Apple’s platform, microLED displays are still challenging to produce and are more expensive. That’s why Apple will start implementing the technology with the Apple Watch Ultra before mass-producing microLED displays for the iPhone. When microLEDs do make it to the iPhone, it will be the company’s reward for its huge investments over the years.

MicroLED display technology will allow for higher brightness, reduced power consumption, improved contrast ratios, and other benefits over current iPhones with OLED displays. However, Apple is said to be years away from bringing the technology to iPhone displays.

Source link

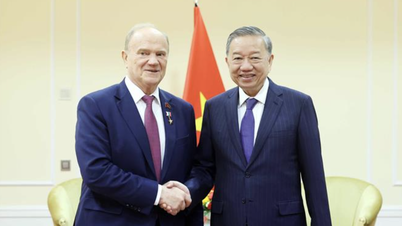

![[Photo] General Secretary To Lam arrives in Minsk, begins state visit to Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/76602f587468437f8b5b7104495f444d)

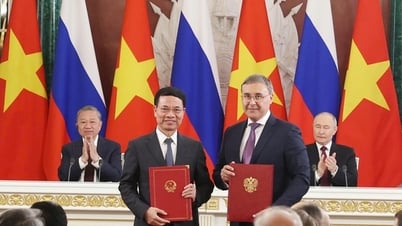

![[Photo] General Secretary To Lam concludes visit to Russia, departs for Belarus](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/0acf1081a95e4b1d9886c67fdafd95ed)

![[Photo] National Assembly Chairman Tran Thanh Man attends the Party Congress of the Committee for Culture and Social Affairs](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/f5ed02beb9404bca998a08b34ef255a6)

Comment (0)