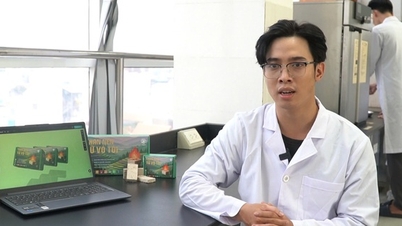

Ms. Nguyen Thi Binh next to her clean vermicelli production system using her traditional method - Photo: C.TRIEU

But when she started her own business, she failed one after another. The financial pressure forced her to return to her profession. And then Nguyen Binh clean vermicelli was born with organic rice ingredients and a commitment to the health of consumers.

Ms. NGUYEN THI BINH

After leaving, we still return to the same noodles.

On the bus to the organic rice fields of the input rice material area of Nguyen Binh Production - Trade and Service Joint Stock Company in Long An province, the life story of Ms. Nguyen Thi Binh is like a slow-motion movie.

Her family has been making vermicelli for five generations in Lien Bat commune, Ung Hoa district (former Ha Tay province, now Hanoi). Understanding the hardships of the profession, staying up late and waking up early, she did not want to follow in her footsteps. Nguyen Thi Binh chose to move to the South as a rejection of the family profession, studying intermediate machine assembly in Dong Nai.

Not wanting her daughter to follow a career traditionally reserved for men, her family did not provide any financial support. To earn money for her education, Binh worked as a handyman, doing whatever was asked of her, from peeling cashews, cutting sugarcane to construction work, washing dishes... But after graduating from high school, she still could not find a job, so she had to juggle many jobs at the same time.

With a little capital, Binh learned makeup and opened a shop, but it was not enough to pay rent. She was very frugal, but the little capital she had saved just went out. Not giving up easily, she went to sell pork. Selling was also difficult because the old ghosts bullied the new ghosts. Not long after, the market was cleared for a project, and the new market was deserted again.

Ms. Binh said she was forced to return to her ancestral profession, even though she hated it.

But it is not possible to return immediately, especially with food products sold during the day. The first batches of noodles made by traditional methods were almost all returned by the market, customers complained that the noodles were black, rough and coarse. Many times the customers returned the goods, Nguyen Thi Binh was left with almost nothing.

Technology for clean noodles

Ms. Nguyen Thi Binh chose a more difficult path when returning to her ancestral profession, making vermicelli - Photo: CONG TRIEU

She smiled and said that the noodles she made looked darker on the outside because they didn't use bleaching preservatives. But it was hard to explain to each person in just a few words, so Binh gave the noodles to people with the thought "if you haven't eaten it, how would you know how delicious it is just by looking at the outside". After giving away tons of noodles for free several times, people started to ask curiously about Nguyen Binh's clean noodles.

But alone, how can the traditional way of "playing" to produce industrial vermicelli popular in Ho Chi Minh City. At the crossroads, she had to choose either the method of soaking rice for half a day, using chemicals to help the rice soften quickly, become shiny, then grind it into flour and cook it into vermicelli, or the traditional way of using clean organic rice that has been soaked for a full week and gone through 15 steps before being ground and cooked.

Ms. NGUYEN THI BINH

I chose the old way, which means soaking the rice for a full week, 15 steps, no softening or polishing chemicals, but the noodles are still sweet and fragrant. The noodles cannot be as white as if they had been bleached, but they are definitely clean.

Considering the idea, the main thing is to calculate how to meet the demand, which can be up to tons of noodles per day. Taking visitors to visit the production workshop on Huynh Van Nghe Street (Tan Binh District, Ho Chi Minh City), Ms. Binh said that she buried her head in the drawing board for three consecutive days, then worked with dozens of engineers to create the current machine system with a capacity of up to 45 tons of finished noodles per day.

With her knowledge of machinery, she operates a boiler to produce traditional vermicelli. The technology allows for remote heating, increases labor safety, does not emit carbon, reduces dust and smoke... Although maintaining the traditional rice fermentation formula, the application of new technology helps increase the shelf life of vermicelli and pho noodles to two days compared to just using them the day before.

Having been a family business for generations, having gone bankrupt and fallen into debt because of vermicelli, Ms. Binh is more confident than anyone else in the industry. So instead of importing cheap rice floating around the market, she imports rice that has passed quality inspection, has organic food certification, is clean and ensures safety for buyers.

Once, the noodles were ruined because they were made using well water, and then the groundwater source was heavily contaminated with pH. So this time, the owner of Clean Noodles invested in an RO filtration system to ensure the quality of water used for production.

Fierce price competition

Ms. Binh said she knew that her clean noodles would have difficulty competing on price with existing fresh noodles because consumers’ preference for cheap products was still widespread. Not to mention that products labeled Organic were not familiar to the majority.

On the other hand, 1kg of conventional rice through mass production methods can currently produce about 3.4kg of vermicelli (the retail price in Ho Chi Minh City is currently 12,000 VND/kg). Meanwhile, 1kg of organic rice produced by the method that her facility is using only produces 1.6kg of vermicelli, so the price of Nguyen Binh Organic fresh vermicelli is currently 26,000 VND/kg.

"Many kitchens and schools signed contracts with us, but after only the first month, the number of orders gradually decreased. Instead, they imported cheap noodles from outside and asked the company to issue invoices to legalize them. In this case, we refused outright because at this point, we would rather accept losing customers than deceive them," Ms. Binh confided.

In addition to vermicelli, the facility currently supplies the market with about 20 different rice-based products such as pasta, pho, wet rice noodles, rice vermicelli...

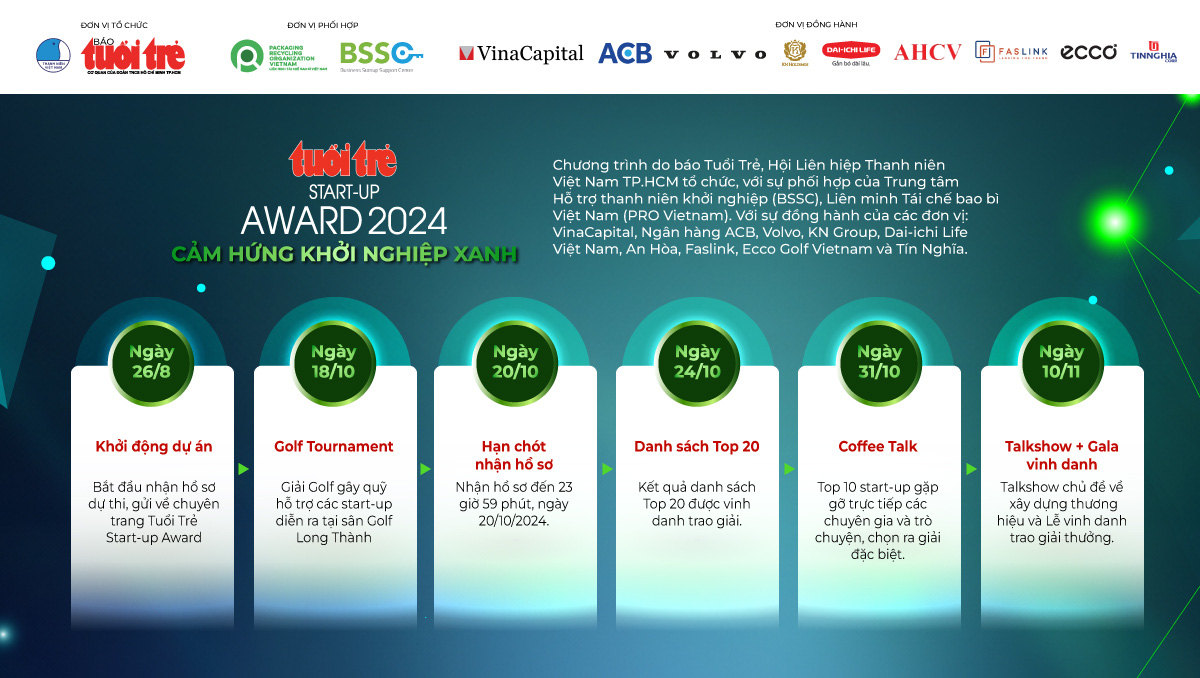

20-10: Deadline for submitting project registration

Tuoi Tre Start-up Award 2024 is organized by Tuoi Tre newspaper and the Ho Chi Minh City Youth Union, in collaboration with the Business Startup Support Center (BSSC) and the Vietnam Packaging Recycling Alliance (PRO Vietnam).

The judging panel will contact and connect with startups through the special Coffee Talk judging format. Promising startups will be honored at the gala scheduled to be held in November 2024.

In addition to sharing stories in the press, startup projects participating in the program have the opportunity to access many investment funds as well as have their images communicated and promoted to the community.

The top 20 startups selected for the final round will receive financial support from the following organizations: VinaCapital, ACB Bank, Volvo, KN Group, Dai-ichi Life Vietnam, An Hoa, Faslink, Ecco Golf Vietnam, Tin Nghia...

The special prize (100 million VND) from the program's advisory board is Mr. Pham Phu Ngoc Trai - Chairman of PRO Vietnam.

The program is accepting project applications until October 20 at email: [email protected] , or visit the Tuoi Tre Start-up Award 2024 website to receive the registration form and submit entries.

Bringing the quintessence of Cham Chu down the mountain to help people

Bringing the quintessence of Cham Chu down the mountain to help peopleSource: https://tuoitre.vn/tuoi-tre-start-up-award-thao-thuc-voi-soi-bun-sach-20241010220659119.htm

![[Photo] Prime Minister Pham Minh Chinh receives Country Director of the World Bank Regional Office for Vietnam, Laos, Cambodia](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/2c7898852fa74a67a7d39e601e287d48)

![[Photo] In May, lotus flowers bloom in President Ho Chi Minh's hometown](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/aed19c8fa5ef410ea0099d9ecf34d2ad)

![[Photo] President Luong Cuong attends the National Ceremony to honor Uncle Ho's Good Children](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/9defa1e6e3e743f59a79f667b0b6b3db)

![[Photo] Close-up of An Phu underpass, which will open to traffic in June](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/5adb08323ea7482fb64fa1bf55fed112)

Comment (0)