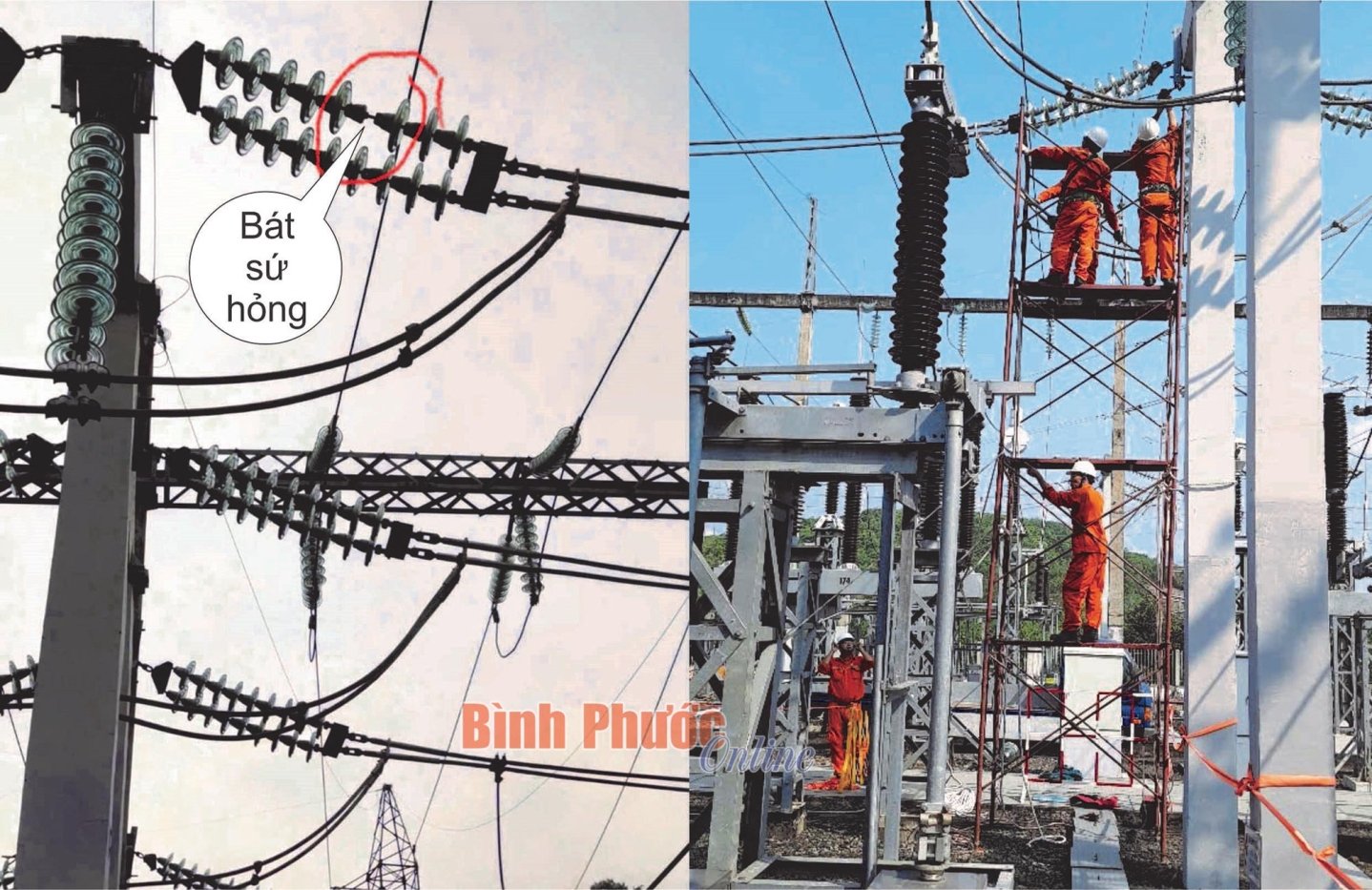

During a recent routine inspection, the Electrical Equipment Team - Electromechanical Service and Repair Center (TMP) replaced the C-phase porcelain string at the TC12/2 busbar gate pillar after discovering a broken porcelain bowl during a routine inspection. Although the incident did not immediately affect operations, there was a potential safety risk if not handled promptly. TMP quickly developed a technical plan, coordinated with the SSO Dispatching level to isolate the equipment (TC12 busbar and compartment 174), mobilized human resources and equipment to implement the replacement.

The operating workshop isolates the equipment according to the correct procedure, ensuring absolute safety. The work of replacing the porcelain chain is carried out according to the work order, following the steps: Issuing work order, supervising safety, installing sturdy scaffolding, supporting operations at height. The new porcelain chain is installed with the correct type, tightening bolts and joints, ensuring mechanical structure and safe electrical conduction.

In the hot weather, TMP's technical team still strictly followed the process, completed the task on schedule, and ensured the quality of the work. The incident handling at the 110kV station not only demonstrated professional capacity but also the company's commitment to providing safe and continuous electricity to serve socio -economic development, especially during the country's important holidays.

Source: https://baobinhphuoc.com.vn/news/4/171827/thuy-dien-thac-mo-no-luc-van-hanh-phat-dien-an-toan-hieu-qua

![[Photo] General Secretary To Lam attends the conference to review 10 years of implementing Directive No. 05 of the Politburo and evaluate the results of implementing Regulation No. 09 of the Central Public Security Party Committee.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/2f44458c655a4403acd7929dbbfa5039)

![[Photo] Panorama of the Opening Ceremony of the 43rd Nhan Dan Newspaper National Table Tennis Championship](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/5e22950340b941309280448198bcf1d9)

![[Photo] President Luong Cuong presents the 40-year Party membership badge to Chief of the Office of the President Le Khanh Hai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/a22bc55dd7bf4a2ab7e3958d32282c15)

![[Photo] Close-up of Tang Long Bridge, Thu Duc City after repairing rutting](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/086736d9d11f43198f5bd8d78df9bd41)

![[VIDEO] - Enhancing the value of Quang Nam OCOP products through trade connections](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/17/5be5b5fff1f14914986fad159097a677)

Comment (0)