The concept of green productivity was introduced by the Asian Productivity Organization (APO) in 1994. Green productivity is a combination of appropriate tools, techniques and technologies to reduce environmental impacts from activities, goods and services of organizations and enterprises; at the same time, it allows efficient use of resources to improve productivity.

Applying green productivity brings many benefits to enterprises by saving production and operating costs, creating environmentally friendly products and services, and building enterprises that are responsible to the community. At the same time, applying green productivity also helps enterprises easily access green credit sources; expanding domestic and foreign markets.

|

| Employees of XDD Textile Co., Ltd. promote research on innovative initiatives in production processes. |

In the context of climate change and the increasingly urgent need for sustainable development, green productivity has become a development strategy for enterprises. In Quang Ngai, recently, a number of medium and large enterprises have focused on promoting the application of green productivity and brought about clear results.

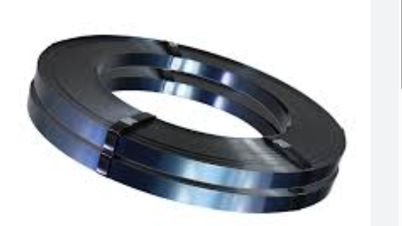

XDD Textile Co., Ltd. is one of the enterprises in the province promoting the application of green productivity. The company has deployed management systems, 5S tools, MFCA in all stages of yarn production, from input to finished output products. Thanks to that, in 2024, the company saved about 750 tons of cotton compared to the previous year, while the company's production output reached more than 53 thousand tons of yarn, exceeding the plan by 1,300 tons.

Deputy Director of Production Engineering Department, Textile Construction Company Limited Nguyen Thi Thom said that currently, the textile industry is facing many challenges in terms of competition as well as strict requirements on international quality standards for export products. Therefore, in recent times, the company has promoted encouraging employees to successfully research initiatives on quality improvement, saving raw materials and increasing output. For example, improving the gaps between cotton drops to reduce cotton drops during processing and combing stages; changing the design of finished product packaging to save costs, reduce emissions while still increasing quality and productivity.

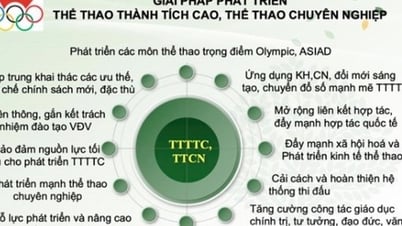

Through the National Program to support enterprises in improving productivity and quality of products and goods in the period of 2021 - 2025 in the province, in 2024, the Department of Science and Technology organized 3 training courses on green productivity for 150 managers and technical staff of enterprises, focusing on content from general awareness to practical guidance on tools and techniques in green productivity, organizing field surveys at enterprises to provide professional knowledge, helping enterprises deploy applications at their units.

According to Deputy Director of the Department of Science and Technology Tran Cong Hoa, although the concept of green productivity is becoming more and more popular, most enterprises in the province are still confused and do not fully understand this model. In the coming time, the Department of Science and Technology will continue to advise on developing specific plans and programs suitable to the actual situation. Promote propaganda work, invite experts and scientists to share with the business community in the province about green productivity, circular economy, green growth, greenhouse gas emissions - Net Zero target... In particular, promote research activities, application of science and technology on green productivity, circular economy in both industrial and agricultural production.

Article and photos: MY DUYEN

Source: https://baoquangngai.vn/kinh-te/202504/thuc-day-kinh-te-tuan-hoan-thong-qua-nang-suat-xanh-62d340b/

![[Photo] Prime Minister Pham Minh Chinh chairs conference on anti-smuggling, trade fraud, and counterfeit goods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/14/6cd67667e99e4248b7d4f587fd21e37c)

Comment (0)