Grasping the trend of consumers preferring to use cups and plates made from organic materials, a group of students in Da Nang City have created a dish press machine from environmentally friendly materials to replace plastic.

Students spread green lifestyle

A group of students including Le Van Tuan, Dang Huu Tai, Mai Xuan Son, Phan Tan Sang, Ho Van Ly (Faculty of Mechanical Engineering, University of Technical Education, University of Da Nang) soon came up with the idea of making a dish press machine from environmentally friendly materials to create biodegradable products, replacing plastic items.

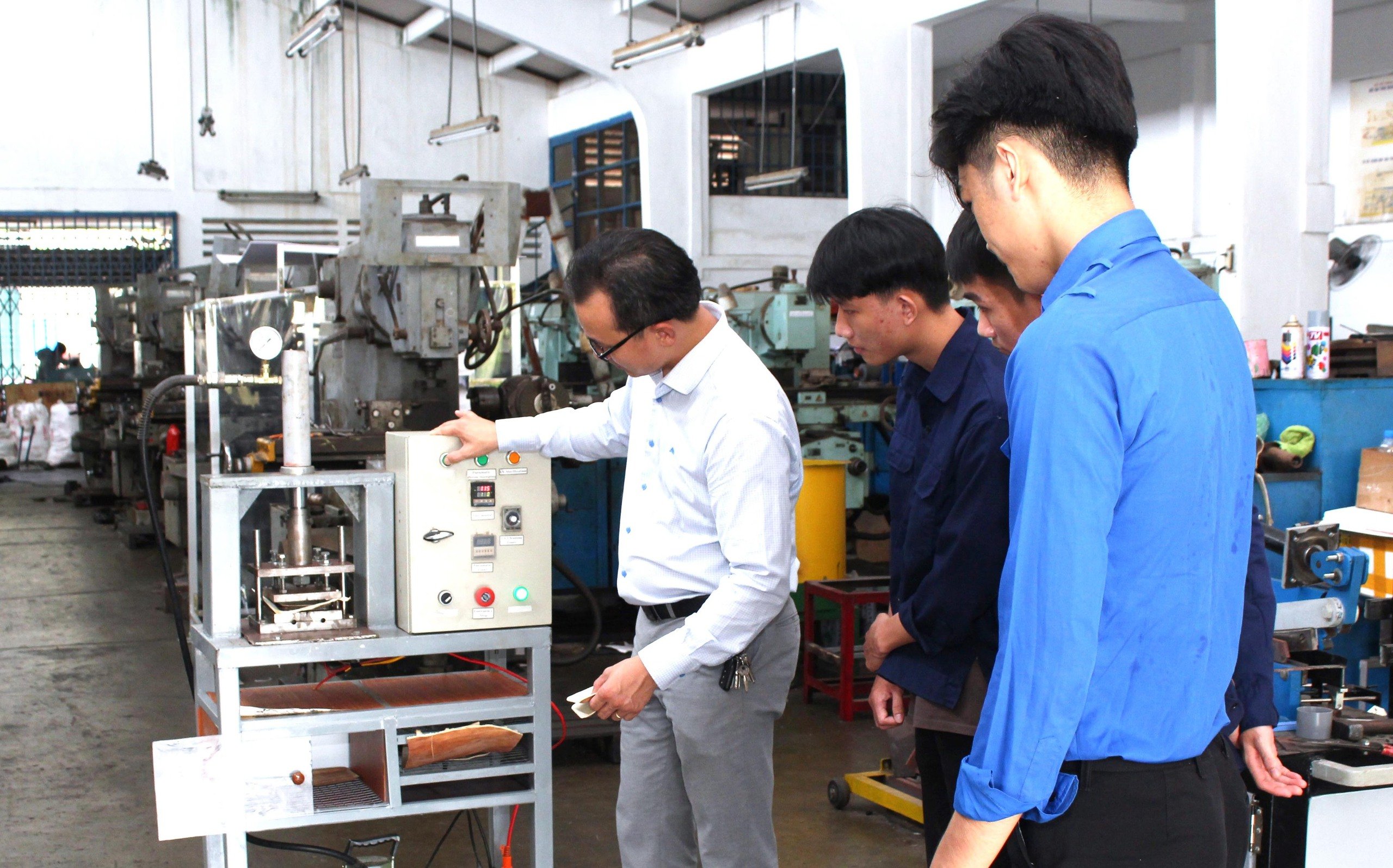

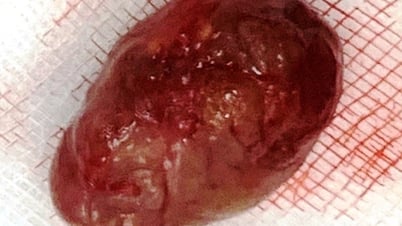

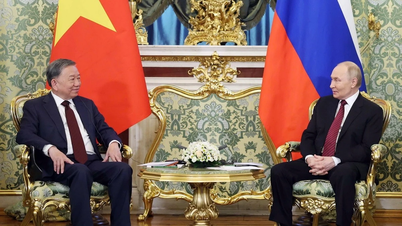

Dr. Bui He Sy (left) guides students in researching and perfecting a dish press from environmentally friendly materials.

The idea was good, but this group of students failed many times in the process of researching and manufacturing the machine. With the guidance of Dr. Bui He Thong (lecturer of the Faculty of Mechanical Engineering), the group of students finally succeeded. The machine that fully met the criteria for manufacturing environmentally friendly products was born.

Dr. Bui He Thong said that the research and design of a cup and plate pressing machine from available materials such as coconut bracts, areca bracts, banana leaves, lotus leaves, and Indian almond leaves is very practical, because it not only solves the problem of green product consumption but also helps develop a sustainable economy. This source of organic materials is also easy to find in the Central provinces, is low cost, and is easily biodegradable, creating an effective cycle of resource reuse.

"Researching, designing and manufacturing environmentally friendly dishwashing machines not only provides technological solutions but also promotes a green lifestyle in the community," Dr. Thong emphasized.

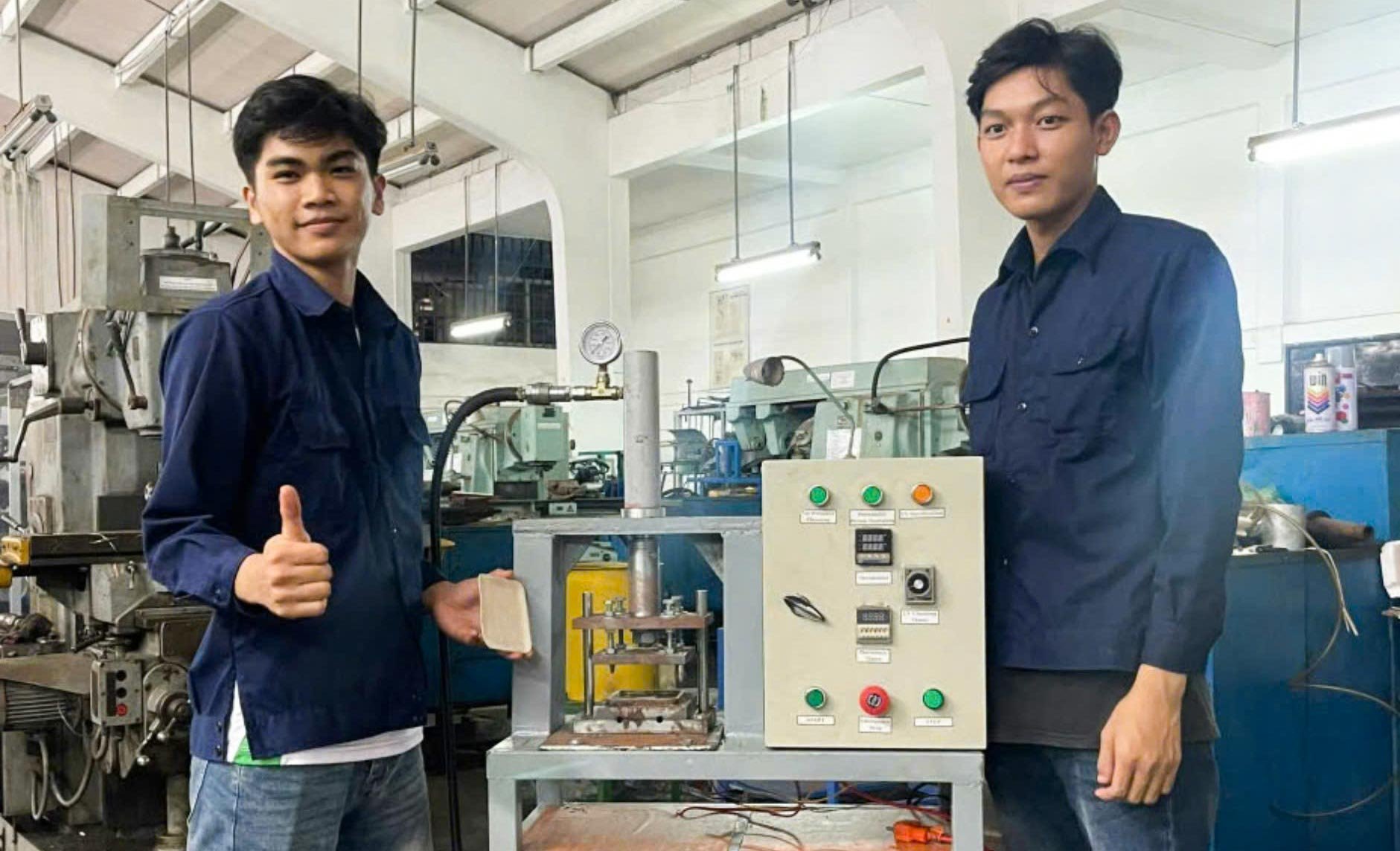

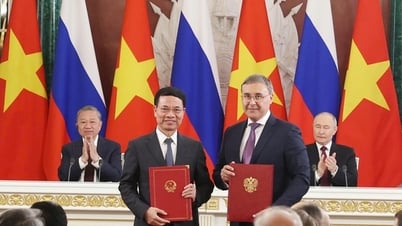

Dishwasher made from environmentally friendly materials by a group of students in Da Nang

Products for future generations

Dang Huu Tai (research team member) said that the dish press machine consists of the following parts: hydraulic power and control system, heating system, pneumatic cleaning system and ultraviolet (UV) sterilization system.

When the machine is started, the heating system starts working, the thermostat will increase the temperature to about 120 - 180 degrees Celsius in 60 - 90 seconds.

"Next, the machine will clean the raw materials with high-pressure air to push the dirt out. After that, the product is shaped by a hydraulic machine, the piston creates pressure, cuts, combined with high temperature. The finished product will be put into a UV sterilization box," Tai informed.

Cups and plates are made from organic, biodegradable materials to replace plastic items.

Le Van Tuan (a member of the research team) added that during the manufacturing process, the team faced many difficulties. Among them, the research on the force generation system was the most difficult problem. Because the actual stamping force is divided into many levels of force to be able to press and block the blank, deform the material and overcome the friction between the material and the upper and lower molds...

"After a period of testing, the team chose a hydraulic control system to optimize the force to create the most perfect product shape. Specifically, when putting the areca spathe into the mold, the user presses the air cleaning button on the control panel to power the control circuit. Air from the pressure tank will pass through the 5/2 valve to the nozzle, creating a high-pressure air flow to push dirt on the surface. A significant advantage is that the machine is optimally designed with a compact size, aesthetics, high safety, and ease of use...", Le Van Tuan shared.

The cost of making the machine was also a headache for the student group. Le Van Tuan said: "To make the dish press, the student group received 4 million VND from the school. Mr. Thong and the group members contributed another 2 million VND to start researching and making it."

Dishwasher made from environmentally friendly materials by a group of students from the University of Technical Education, University of Danang

After a period of hard work, the student group's product won first prize in the school-level Student Scientific Research Competition. This topic was also selected to continue to compete in the final round of the Da Nang City-level Student Scientific Research Competition in the near future.

"Currently, there are some gardeners and farmers who are interested in ordering our products. In the coming time, the group will continue to develop and perfect the pressing machine system, in order to widely distribute products to the market, at the most suitable price. From there, consumers can join hands to reduce plastic waste, protect the living environment for future generations," said Le Van Tuan.

Source: https://thanhnien.vn/sinh-vien-san-xuat-chen-dia-tu-mo-cau-la-chuoi-gop-suc-cho-song-xanh-185241122170148657.htm

![[Photo] National Assembly Chairman works with leaders of Can Tho city, Hau Giang and Soc Trang provinces](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/c40b0aead4bd43c8ba1f48d2de40720e)

![[Photo] Prime Minister Pham Minh Chinh chairs the fourth meeting of the Steering Committee for Eliminating Temporary and Dilapidated Houses](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/e64c18fd03984747ba213053c9bf5c5a)

![[Photo] The moment Harry Kane lifted the Bundesliga trophy for the first time](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/68e4a433c079457b9e84dd4b9fa694fe)

![[Photo] Discover the beautiful scenery of Wulingyuan in Zhangjiajie, China](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/11/1207318fb0b0467fb0f5ea4869da5517)

![[Video] Prime Minister directs 3 "hot" issues of the education sector](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/11/7e31b727b1264eda82eca75f579349d1)

Comment (0)