|

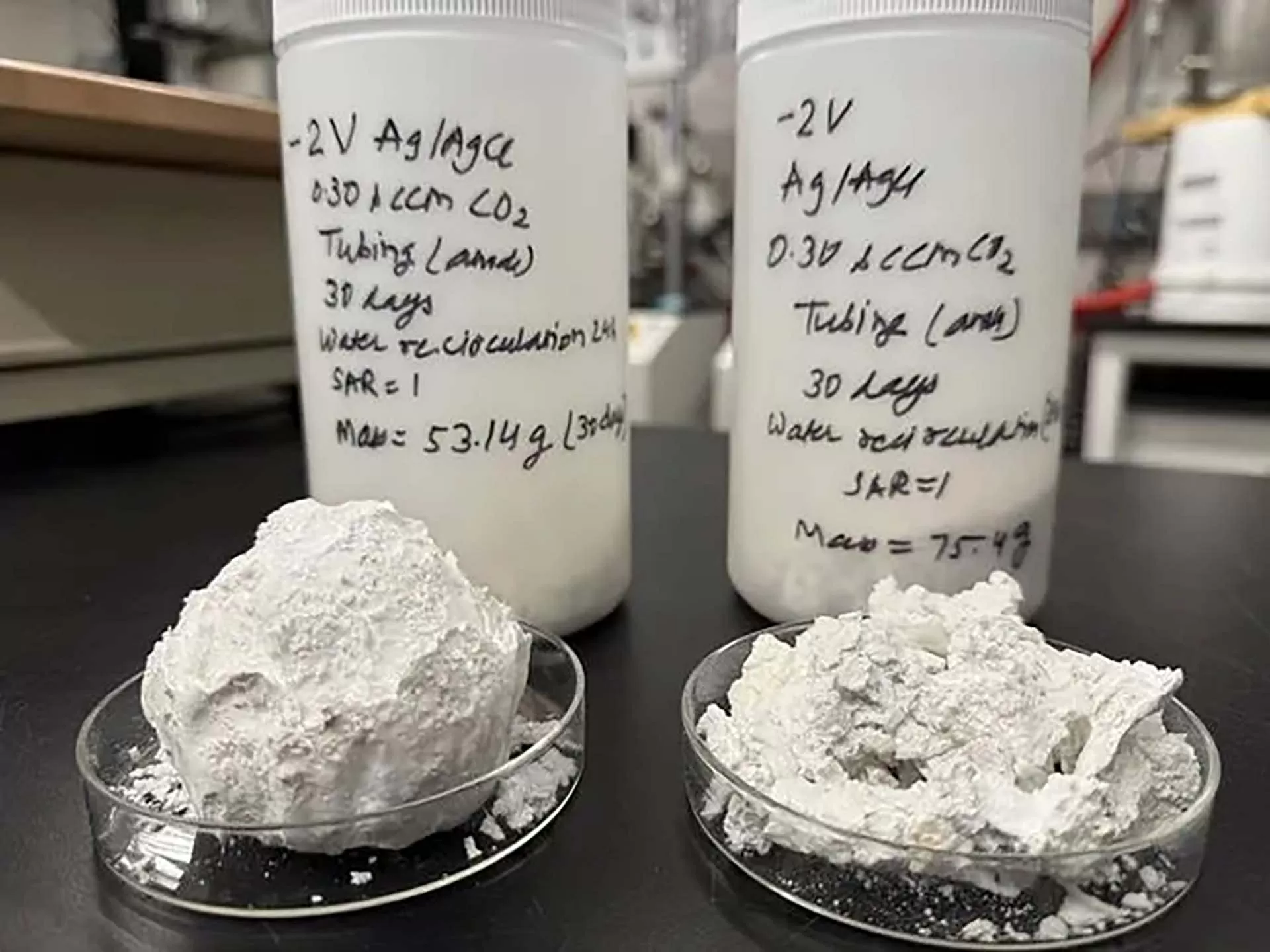

| Seawater electrolysis could be a carbon-neutral way to produce cement and other building materials. (Source: Northwestern University) |

The cement industry currently contributes around 8% of global CO₂ emissions, making it the world's fourth-largest emitter, largely due to the extraction of raw materials from mountains, rivers and seabeds, the report said.

Faced with this situation, researchers at Northwestern University (USA), in collaboration with the innovation department of the Cemex Cement Group in Switzerland, developed a more environmentally friendly cement. They used the technique of seawater electrolysis (a method of splitting water molecules with electricity) to create hydrogen, chlorine, oxygen and especially calcium carbonate (CaCO₃), the main ingredient for cement.

In the experiment, the team introduced electrodes into seawater, adjusted the voltage, and injected CO₂ at different rates and volumes to control the pH. This fine-tuning allowed control of the volume, chemical composition, and crystal structure of the CaCO₃, resulting in minerals with different porosity or density. However, the current electrolysis rate is still too slow to meet industrial needs. Therefore, the team is continuing to investigate the mechanism of mineral formation during electrolysis and ways to increase production.

This discovery opens up the prospect of adapting the electrolysis process to produce a variety of minerals and aggregates for the construction industry. If done with electricity from renewable sources, this process would not only be carbon neutral but also contribute to reducing the amount of CO₂ in the atmosphere.

Source: https://baoquocte.vn/san-xuat-xi-mang-xanh-311511.html

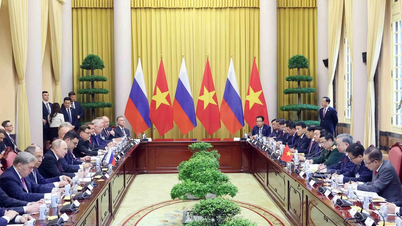

![[Photo] General Secretary To Lam begins official visit to Russia and attends the 80th Anniversary of Victory over Fascism](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/5d2566d7f67d4a1e9b88bc677831ec9d)

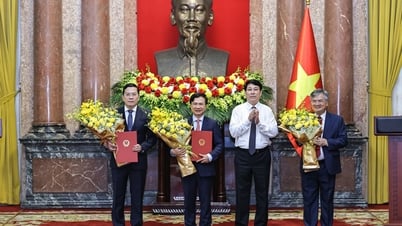

![[Photo] President Luong Cuong presents the decision to appoint Deputy Head of the Office of the President](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/501f8ee192f3476ab9f7579c57b423ad)

![[Photo] National Assembly Chairman Tran Thanh Man chairs the meeting of the Subcommittee on Documents of the First National Assembly Party Congress](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/72b19a73d94a4affab411fd8c87f4f8d)

![[Photo] Prime Minister Pham Minh Chinh meets with the Policy Advisory Council on Private Economic Development](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/387da60b85cc489ab2aed8442fc3b14a)

![[Photo] General Secretary concludes visit to Azerbaijan, departs for visit to Russian Federation](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/8/7a135ad280314b66917ad278ce0e26fa)

![[Photo] Prime Minister Pham Minh Chinh talks on the phone with Singaporean Prime Minister Lawrence Wong](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/8/e2eab082d9bc4fc4a360b28fa0ab94de)

Comment (0)