Textile and dyeing industry towards sustainable development

The Provincial People's Committee has agreed to establish a textile and garment industrial zone and supporting industry in the industrial parks: Phuoc Dong, TMTC, Thanh Thanh Cong, the textile and dyeing zone is only for dyeing products manufactured in the textile zone of the industrial park.

Currently, the province has proposed many solutions to attract all resources from economic sectors to invest in developing the textile and footwear industry; focusing on and gradually developing and attracting investment projects to produce highly competitive products, industrial and supporting products, new raw materials of natural origin, and environmentally friendly.

Contribute to gradually increasing the proportion of industry in GRDP

In the province, there are currently 6 licensed industrial parks established and operating with a total land area of 3,491 hectares, industrial land available for lease is 2,616 hectares, 1,763 hectares have been leased, reaching a occupancy rate of 67.37%.

Accordingly, in the province, there are currently 5/6 industrial parks with textile and dyeing projects in operation. There are 60 textile and dyeing projects attracting investment in 5 industrial parks in the province, with a total registered investment capital of 3,421 million USD, a total land area of 717.58 ha/1,763 ha, creating jobs for more than 39,000 workers, accounting for 29.54% of domestic workers working in industrial parks.

Of the total 60 textile and dyeing projects mentioned above, 40 projects have been built and put into operation, while 20 projects have not yet been put into operation.

Textile and dyeing projects have attracted and created a large number of jobs, contributing to increasing the occupancy rate of industrial zones, making an important contribution to the economic restructuring of the province towards gradually increasing the proportion of industry in GRDP, contributing to import-export turnover, expanding budget revenue, and creating stable jobs for the local labor force.

According to the Department of Industry and Trade, export turnover in March 2025 is estimated at 576 million USD, up 13.45% over the previous month and up 77.95% over the same period last year. In the first 3 months of 2025, export turnover is estimated at 1,650 million USD, up 11.5% over the same period in 2024.

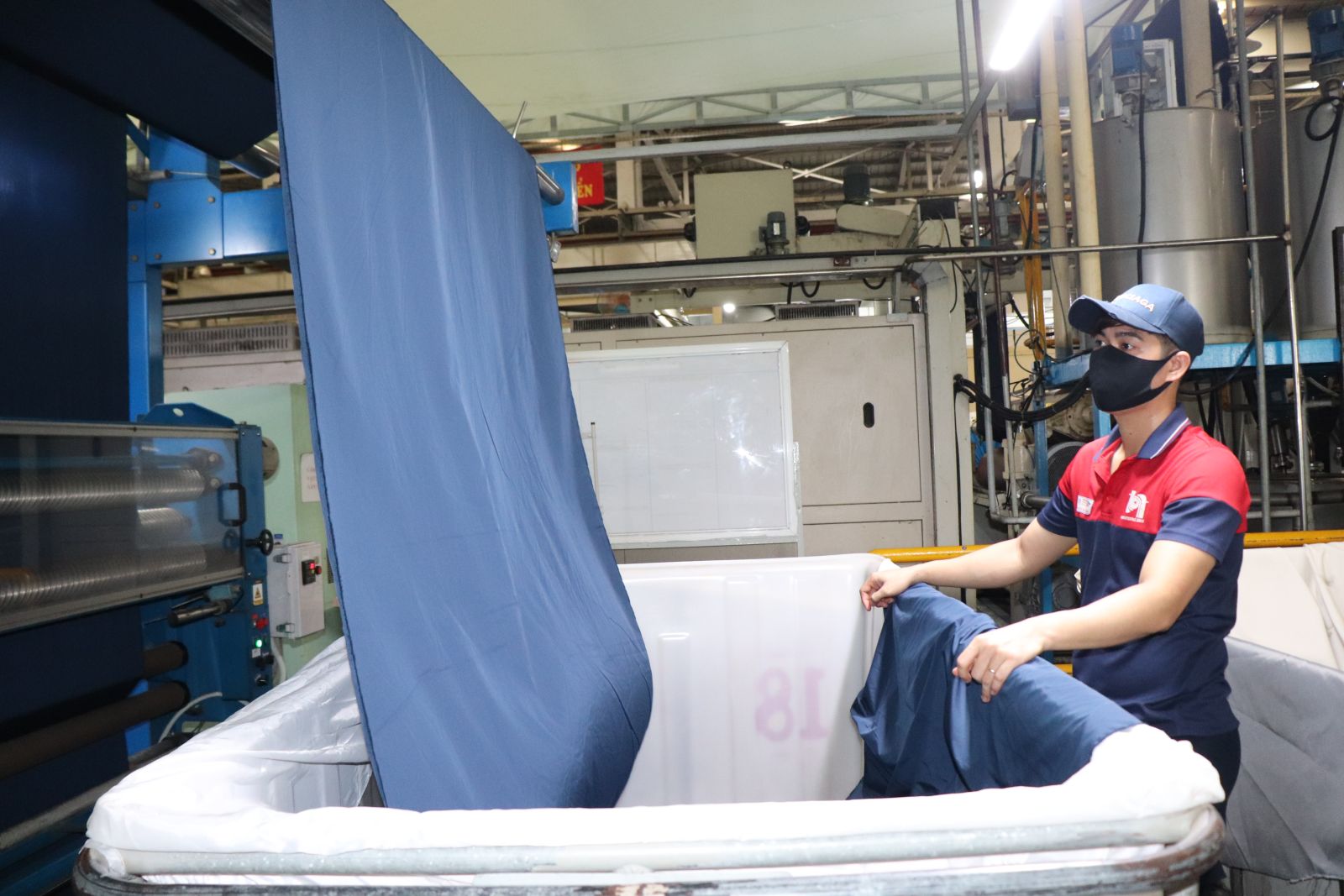

Tran Hiep Thanh Textile Joint Stock Company (THHTTEX) said that the company is not only a 100% Vietnamese enterprise with strong growth but also a model of sustainable textile and dyeing industry in Vietnam. With a strategy of technological innovation, market expansion, production optimization and investment in green product development, the company continues to affirm its position as a Vietnamese textile brand that meets international standards.

Tran Hiep Thanh Textile Joint Stock Company is included in FAST500 - the ranking of Top 500 fastest growing enterprises in Vietnam 2025 conducted by Vietnam Report in collaboration with VietnamNet. This is a clear demonstration of the strong, sustainable and effective development of enterprises in the textile and garment industry.

FAST500 evaluates businesses based on the CAGR (compound growth rate) index of revenue, operational capacity, financial situation and reputation in the market. THTTEX's presence in the 2025 list (the previous 2 times in 2021 and 2022) this time affirms that the company not only achieves a high growth rate but also maintains stability in operations and long-term development strategy.

Prioritize environmental protection criteria associated with a green, clean environment.

With the nature of the textile and dyeing industry being rich and diverse in product types, there are over 22 types of fabric products such as cotton, khaki, wool, spandex, polyester, velvet, linen, synthetic... Corresponding to each type of product and input material, the usage standards for clean water, chemicals, energy, processes, and technology to produce the product are different.

Textile and dyeing projects discharge large volumes of wastewater (the wastewater generated accounts for about 88% of the clean water used), mainly arising in the cooking, bleaching, dyeing, and washing stages. The composition of wastewater depends on the characteristics of the dyeing materials, the nature of the dyes, the auxiliary substances and other chemicals used, and the main pollutants in the wastewater, thus requiring strict control of the quality of treated wastewater from projects before discharging into the environment.

The production and business activities of textile and dyeing projects are part of the global supply chain. The trend of global consumers is increasingly towards safety, comfort, convenience, beauty... especially towards environmental sustainability.

Increasing customer demand forces businesses to change their production methods, including the requirement to raise environmental and social standards. Product production must be associated with a green, clean and sustainable environment. If production methods are not changed, they will be eliminated.

Enterprises that do not apply solutions to save energy, natural resources... are at risk of having orders stopped or being rejected. In addition to inspection and supervision by state management agencies on environmental protection, enterprises are also inspected and supervised by customers, so enterprises are always aware of environmental protection, using environmentally friendly raw materials, fuels, materials, saving energy, and minimizing waste generation. With the development of science and environmental technology today, all types of waste generated from textile and dyeing projects during the production process can be collected and treated to meet the requirements of environmental protection laws.

Tran Hiep Thanh Textile Joint Stock Company said that to achieve stable revenue growth, the company relied on increasing orders from strategic partners. At the same time, with close cooperation with partners and customers from Europe, America, Japan such as: Decathlon, Columbia, Uniqlo, Toyo Orimono, Aurora Investment Global... revenue from international markets continuously grew.

Currently, the company not only focuses on output but also invests in high value-added products to meet diverse market needs. In addition, the company is constantly expanding its export markets to the US, Europe, and Japan, areas with strict standards but high profit margins.

Focusing on exports helps THTTEX maintain high growth. Currently, the company reaches high-end markets and has a strong presence in Europe, the US, and Japan, taking advantage of trade agreements such as EVFTA and CPTPP.

Regarding product diversification strategy, the company develops specialized fabric lines for each market, such as UV-resistant fabric for Japan, recycled fabric for the European market; optimizes logistics and supply chain: improves warehouse and transportation systems, reduces logistics costs to enhance product competitiveness.

To maintain sustainable growth in the coming years, Tran Hiep Thanh Textile Joint Stock Company researches and applies AI and Big Data in quality control and market demand forecasting; invests in automatic production lines, reducing dependence on manual labor.

In addition, the unit reuses water in the dyeing process, aiming to reduce 30%-40% of water consumption; promote exports to new markets; seek opportunities to participate in international textile fairs, and opportunities to cooperate with large corporations.

Tran Hiep Thanh Textile Joint Stock Company added that in order for the textile dyeing industry to develop sustainably, the company prioritizes the use of biomass fuel instead of fossil fuels, aiming to completely eliminate the use of coal in the factory by 2026; research and deploy solar power, reduce electricity costs and reduce CO₂ emissions; orient the application of environmentally friendly dyeing chemicals, reduce wastewater pollution; reuse scraps, aiming for a circular economic model in production.

Prioritize projects that comply with environmental laws.

Textile and dyeing projects have not yet been developed, require a lot of labor, and affect labor shortages in other fields; use a lot of water, chemicals, additives, and dyes, and consume more electricity than other projects; have a large amount of wastewater; and the export ratio does not correspond to the value of the contribution to the budget compared to other fields.

After consulting the policies of some provinces in the Southeast region on the current status and orientation of receiving investment projects with high risk of environmental pollution, including the textile and dyeing industry, the Party Committee of the Provincial People's Committee proposed that for newly established industrial parks (Hiep Thanh Industrial Park) and newly planned industrial parks according to the Provincial Planning, not consider attracting textile and dyeing industries and industries with high risk of environmental pollution.

For textile and dyeing zones in industrial parks that have been approved and fully meet environmental protection regulations, continue to consider attracting investment in large-scale textile and dyeing projects that use advanced technology, have synchronous, closed, sustainable production processes, are less labor-intensive, consume less electricity, use little or no water, and have limited wastewater; projects that participate in the production chain of global textile and garment companies, forming links throughout the value chain from the production of raw materials and accessories to high-value final products until the zone is filled.

For projects that have come into operation and have proposed to expand their scale and increase their capacity, priority will only be given to projects that comply with the provisions of the law on environment, investment and construction; have innovative solutions for modern, advanced production technology, save energy, use little or no water, prioritize the use of domestic input materials; the amount of waste generated when expanding production must be consistent with the treatment capacity of the waste treatment facilities of the industrial park infrastructure business unit.

Nhi Tran

Source: https://baotayninh.vn/nganh-det-nhuom-huong-toi-phat-trien-ben-vung-a188893.html

![[Photo] Prime Minister Pham Minh Chinh and Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra attend the Vietnam-Thailand Business Forum 2025](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/1cdfce54d25c48a68ae6fb9204f2171a)

![[Photo] President Luong Cuong receives Prime Minister of the Kingdom of Thailand Paetongtarn Shinawatra](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/16/52c73b27198a4e12bd6a903d1c218846)

Comment (0)