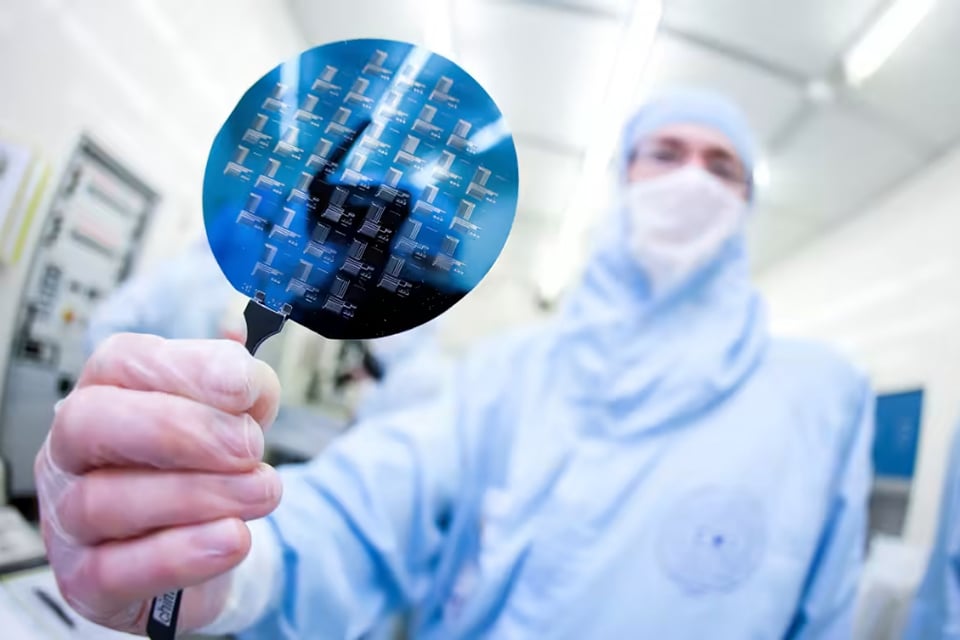

According to Tom's Hardware , building a 2nm chip manufacturing facility with a capacity of 50,000 silicon wafers per month would cost investors $28 billion, compared to the $20 billion needed to build a similar facility for 3nm chips.

The increased cost of producing 2nm chips will mean customers have to pay more.

The reason for this cost increase stems from the demand for more extreme ultraviolet (EUV) lithography machines, which are extremely expensive. Chip manufacturers will ultimately be forced to pass these costs on to production costs, resulting in significantly higher prices for customers.

For Apple specifically, a 300mm silicon wafer with a 2nm chip would cost $30,000 if manufactured by TSMC, while a similar wafer with a 3nm chip would cost $20,000 each. Other TSMC customers would find it more difficult to demand such pricing.

Analysts at IBS say that each A17 Pro chip manufactured using TSMC's 3nm process will cost around $40, but Apple will pay approximately $50 per chip due to the defect rate. Based on their calculations, IBS estimates the production cost of a 2nm chip will be $60 per chip, while Apple's cost will be around $85 per chip.

Some earlier forecasts indicated the price of a silicon wafer for a 2nm chip would be $25,000, so the price range could be quite wide. The upward cost trend is having a heavier impact on developers of monolithic crystal structures. Switching to a multi-chip layout could significantly reduce costs but requires higher-quality chip packaging.

Source link

Comment (0)