The weak and loose linkage is reflected in the low localization rate of domestic industrial products.

Localization rate is not high

According to the Ministry of Industry and Trade , the problem of Vietnam's industry lies in the weak internal strength, the economic restructuring depends too much on FDI enterprises. For example, FDI enterprises account for more than 70% of Vietnam's total export turnover, especially for key export industries such as electricity - electronics, textiles, footwear, the number of FDI enterprises is only about 20% of the total number of enterprises but accounts for more than 80% of export turnover. These enterprises are mainly concentrated in the downstream area to take advantage of tax incentives and input costs such as cheap labor and Vietnam's not too high environmental and labor requirements.

The leader of the Department of Industry (Ministry of Industry and Trade) pointed out the current situation that in recent times, the transformation and restructuring of industrial production has mainly come from the FDI sector, not domestic enterprises; the competitive advantages of connecting economic sectors with localities to create industrial production chains have not been taken advantage of.

" Most supporting industry enterprises are small and medium-sized enterprises, not yet capable of competing with imported goods in terms of price, quality, and delivery schedule. Supporting industry products with high technology content are still mainly provided by FDI enterprises. To serve domestic production and assembly needs, Vietnam still imports components and spare parts with large values " - the Department of Industry pointed out.

Talking to Cong Thuong Newspaper, Ms. Truong Thi Chi Binh - General Secretary of the Vietnam Association of Supporting Industries (VASI) said that it must be recognized that the connection between domestic and foreign investors is still vague, the spillover effect of technology and labor productivity from foreign partners to domestic enterprises is still very limited.

In addition, the weak and loose linkage is reflected in the low localization rate of domestic supporting industrial products. Therefore, further improvement of the localization rate is required to attract more FDI.

For example, the electronics industry is considered to be industry The spearhead plays a big role in exports, but in reality, the group of electronics, computers and components in Vietnam still depends largely on FDI enterprises. The basic reality is that the localization rate of the electronics industry is still low; most of the electronic products in the Vietnamese market are imported or assembled domestically with foreign components; although the supporting industry enterprises in the electronics industry have participated in the value chain of the industry, they can only supply simple products with low technological content.

For example, the automobile industry is an industry that integrates many sub-industries such as precision mechanics, electronics, materials technology, requiring high technology level... but most domestic enterprises cannot meet it.

According to the Ministry of Industry and Trade, the localization rate for personal vehicles with up to 9 seats is still low, the target is 30-40% in 2020, 40-45% in 2025 and 50-55% in 2030, but the actual figure is currently only about 7-10% on average; much lower than the target and compared to countries in the region such as Thailand, Indonesia and Malaysia.

Businesses must strive to assert their strengths.

According to Ms. Truong Thi Chi Binh, Vietnam is a "latecomer" in the process of industrialization and modernization. The Vietnamese government has always rolled out the red carpet and attracted FDI investment. However, the requirement for FDI enterprises to localize is still quite cautious. Therefore, there must be strong enough sanctions for FDI enterprises to implement the localization rate, joint ventures with domestic enterprises to produce components and accessories; set criteria and incentive measures as well as sanctions for FDI enterprises that do not fulfill their commitments on localization rates. The government and relevant ministries and branches need to continue to be more determined and determined in "pressing" FDI enterprises to commit to localization. At the same time, focus on developing domestic supporting industries to retain FDI capital flows.

Currently, Ministry of Industry and Trade has presided over and coordinated with ministries, branches and localities to organize support for industrial enterprises to connect with multinational corporations to seek opportunities to participate in the supply chain for these corporations in Vietnam as well as abroad; effectively implemented preferential policies and investment support according to the provisions of law on industrial development, especially supporting industries.

At the same time, deploy the construction of Technical Centers (based on models of Korea, Japan, Thailand) to support industrial enterprises in general, supporting industrial enterprises, mechanical engineering in particular to improve technical and management capacity, meet the requirements of multinational corporations, FDI enterprises and participate more deeply in the global value chain.

The key industries expected to be identified are supporting industries for the textile, footwear, electronics, automobile manufacturing and assembly, mechanical engineering, high technology; materials and metallurgy industries; mechanical engineering; electronics; food and biological industries, etc.

Ms. Truong Thi Chi Binh also proposed a long-term solution for all industrial sectors, the most important factor is the support and motivation for investment enterprises. Investing in mechanical projects requires large investment capital but low profits, so it is difficult to attract investors. The government needs to have preferential policies to encourage mechanical manufacturing projects to apply modern technology and meet international standards.

Therefore, to continue to create momentum to promote the development of the domestic industrial sector, in addition to efforts to improve the production capacity of each enterprise, the system of policies and mechanisms on supporting industry needs to be completed and implemented more synchronously and effectively. I believe that only then can supporting industry overcome difficulties and challenges and develop sustainably.

Source

![[Photo] Worshiping the Tuyet Son statue - a nearly 400-year-old treasure at Keo Pagoda](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764679323086_ndo_br_tempimageomw0hi-4884-jpg.webp&w=3840&q=75)

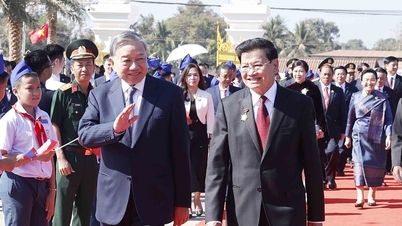

![[Photo] Parade to celebrate the 50th anniversary of Laos' National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764691918289_ndo_br_0-jpg.webp&w=3840&q=75)

Comment (0)