With the spirit of "Vietnam can do," the chairman, who failed the university entrance exam five times, has conquered demanding Japanese customers and is continuing to bring Vietnamese products to many other international markets.

"I came to the mechanical engineering industry by chance," Hoàng Hữu Thắng, Chairman of the Board of Directors of Vietnam Intech Group (Intech Group), recalled thoughtfully.

After graduating from university in 2009, student Hoang Huu Thang made a living selling helmets. However, after two years, realizing that the helmet market didn't have much potential for future growth, given the booming public transportation projects and the increasing number of car buyers, he decided to pursue a different career path.

“After days of searching for information on the internet, I was attracted by images of conveyor belt products, which were widely used in factories and industries. At that time, foreign direct investment (FDI) businesses were pouring into Vietnam, especially Korean and Japanese companies; almost every factory needed conveyor belt products. Having studied mechatronics, I boldly delved deeper into mechanical and engineering products and saw that this industry had many opportunities for development in the context of the country's accelerated industrialization and modernization. Further research on large corporations around the world working in this field, and their modern factories, fascinated me. So I decided to start a business in the field of mechanical engineering and automation, even though my understanding was limited to textbook knowledge from school and a short time researching information online; I had no practical experience whatsoever. At that time, I was only looking ahead, not yet fully aware of the potential.” "Aware of the difficulties and hardships I would face," Mr. Thang recounted about how he came to work in the field of mechanical engineering and automation.

The Vietnam Intech Group Joint Stock Company (abbreviated as Intech Group) was founded at the end of 2011 in a rented house. Hoang Huu Thang set himself the goal of striving his best for 5 years; if successful, he would continue, otherwise, he would return to work in an industrial park in a provincial town.

The early days of starting a business were fraught with difficulties: no experience, no connections, no customers, and no financial resources. My family came from a farming background; my parents were elderly, and most of my relatives lived in the mountainous countryside of Bac Giang province, so they couldn't offer any support.

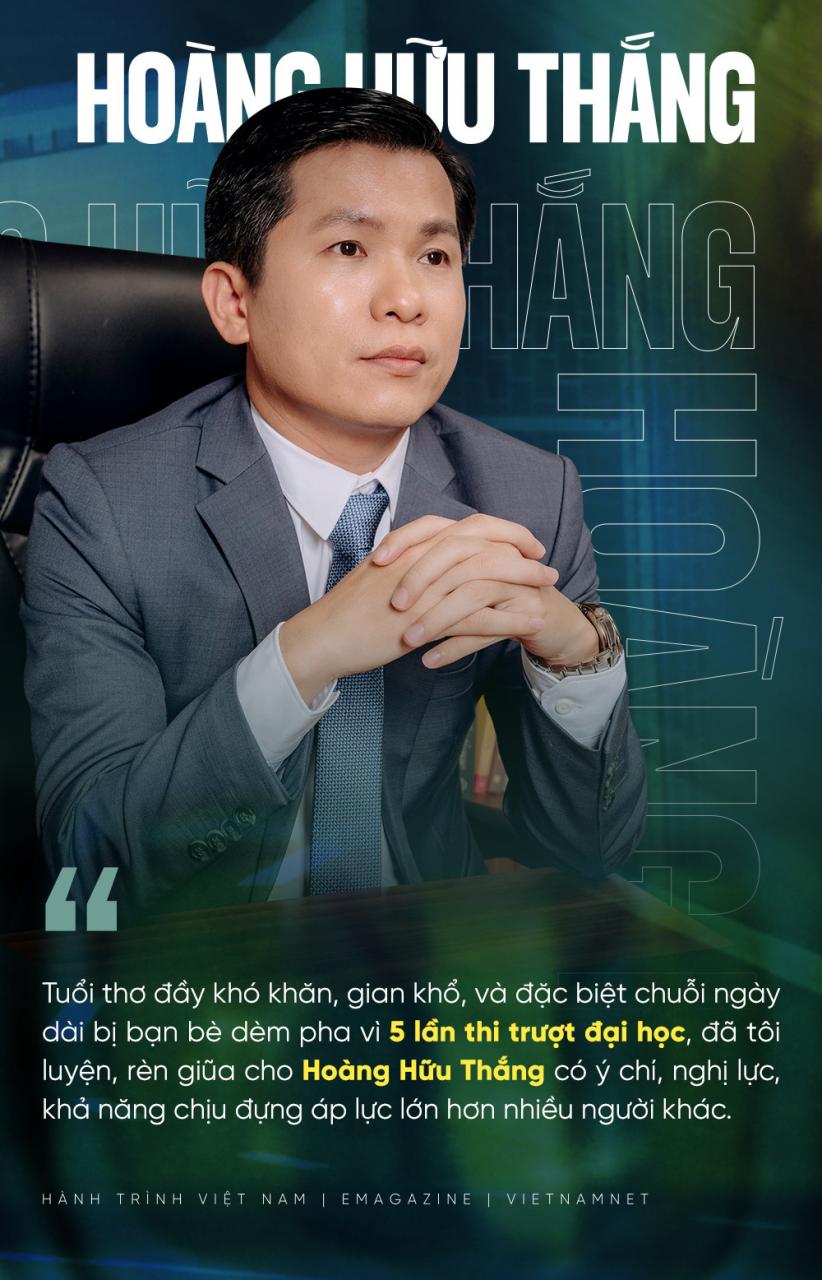

However, a childhood full of hardships and difficulties, such as cycling 20km to sell vegetables in freezing weather with sweat dripping down his back, or spending nights catching shrimp and fish, and especially the long days of being ridiculed by friends and experiencing a range of emotions due to failing the university entrance exam five times, have forged and honed Hoang Huu Thang's willpower, determination, and ability to withstand pressure far greater than many others.

After months of posting classified ads on websites like Vatgia, Rongbay, Muaban… and using online images to promote their products, Intech received its first order.

The order was only worth a little over 10 million VND, so the customer didn't have very high demands regarding factory standards or production capacity. However, because the work was done through an intermediary partner who didn't understand the technical aspects, they misinterpreted the "requirements." Even though Intech manufactured the goods according to the specifications in the contract, the customer still refused to accept the goods and wouldn't return them because they had already paid 50% of the order value in advance. Even the younger brother who went to deliver the goods was detained by the customer. Hoang Huu Thang had to go there in person to explain everything thoroughly before the customer finally understood and let the two brothers go home.

Still owing 6 million dong for goods, the founder of Intech traveled all the way to Xuan Truong district ( Nam Dinh province ) to demand payment from his intermediary partner. After waiting all day without success, he took a motorbike taxi to Nam Dinh city to rest, but was involved in an accident on the way, sustaining many scrapes and bruises. The next day, he continued waiting to demand payment. Fortunately, by noon, the partner finally agreed to pay 3 million dong.

After the first order didn't go smoothly, the founder of Intech continued posting classified ads, using sincerity, integrity, and a proactive approach to work with customers. His efforts paid off; orders started coming in more frequently, mostly small orders for industrial rollers and conveyor belts.

He diligently studied drawing day and night, designing products himself, then commissioning them to be manufactured in small workshops. Workshops with lathes would order lathe-related parts, those with milling machines would order milling-related parts, and so on. Electrical equipment and components were ordered from companies that sold electrical equipment and components. He would then gather all the parts back at his rented room to assemble and test them. Only when everything was satisfactory would he deliver the finished product to the customer.

After a while, when we receive larger orders, we partner with larger factories, having them handle manufacturing, assembly, and even installation later on. Intech focuses solely on the technical aspects and pre- and post-sales services.

By doing it this way, even without its own factory and without investing heavily in machinery and equipment, Intech is still able to produce products that meet the requirements.

In the early days of his company, Hoang Huu Thang devoted all his energy to work, sleeping very little and having almost no time for leisure. “Back then, I was in a relationship. At 11 or 12 midnight, my girlfriend would call to ask what I was doing, and I’d still be assembling conveyor belts, rollers, and products… because I had to deliver them to customers the next morning. I looked very thin then, only about 50-52 kg, my face was gaunt and haggard; everyone said I looked older than my age,” the founder of Intech recalled with a laugh.

Due to limited scale and capacity, even though they wanted to increase revenue, Intech's leadership had to refuse many orders that were too technically challenging or worth billions of dong, given the company's limited capital.

Mr. Thang explained: "I know my capabilities. Refusing is the best solution for both the customer and myself. If I keep accepting orders that I can't handle, it will directly affect the customer's production line and production plan, causing losses for both sides. Neither the customer nor I want that. Later, when resources increase, I can accept more suitable orders according to the company's capabilities."

With the motto of only accepting projects if it's certain it can be done, in its first 5 years of operation, except for the first order, Intech has never had a customer return or refuse to accept goods.

Intech's largest order in its first five years was worth nearly 8 billion VND, supplied to a South Korean factory in Nghe An province. Prior to that, Intech had supplied a production line worth approximately 3 billion VND to the same factory in Hai Duong province.

“Actually, the 8 billion VND order at that time was a bit beyond Intech's financial capabilities. Intech guaranteed the technical aspects and schedule, and frankly shared the actual situation so that they could facilitate the financial arrangements and payment. The customer understood, and we were able to reach an agreement. Orders like that helped the company significantly boost its growth, gradually developing from a company specializing in mechanical manufacturing into a precision engineering, automation, and technology conglomerate that later became Intech Group,” Mr. Thang confided.

Intrigued by the professional, spacious, and clean factories of FDI enterprises, and with more capital at his disposal, the "boss" of Intech decided to build his own factory to have more control over product quality and production schedules.

Initially, it was just an assembly plant. Later, with more stable customers and more consistent work, they started investing in more machinery to take control of production. If they lacked funds, they bought used or second-hand machines to save costs. If they had more resources, they bought brand-new machines from China, Japan, or Europe.

“As the company’s financial situation improves, we invest in higher-quality, more sophisticated machinery to meet the demanding quality requirements of our customers. Intech currently has many machinery lines from Japan and Europe, some of which are worth over 10 billion VND because they are all top-of-the-line models on the market at the time of purchase. Some foreign partners who visit don’t believe this factory belongs to a Vietnamese company; they think it belongs to a foreign owner or has foreign investment,” the Chairman of Intech shared.

To produce parts and components that meet the demanding requirements of discerning customers in terms of both quality and aesthetics, Intech not only invests in modern production lines but also in a rigorous quality control system at every stage, every department, and every employee, with internationally standardized measuring equipment.

Research and development (R&D) activities are seriously invested in and implemented. For example, with industrial rollers that have been exported to the Japanese market for about four years now, customers have very high demands for quality and durability. Intech's research center had to conduct years of testing, inspection, and evaluation before submitting the product to the market, with clear measurement indicators to prove the quality and production process.

Having used rollers supplied by Intech, Mr. Eisei Hirata, Head of Supply and Planning at Tsubakimoto-chan Company, highly praised the Vietnamese company's products: "All of our major projects use Intech rollers. After 5 million durability tests of Intech products compared with other domestic brands, we assess Intech rollers as having the highest durability and best quality."

The Chairman of Intech Group stated: "To achieve sustainable development, we must invest heavily in research and development. Starting over from scratch is perfectly normal, accepting that it will cost a great deal of resources in terms of finance, personnel, time, and effort."

Intech's research center currently has nearly 20 staff members, including mechanical engineers, electrical engineers, control engineers, software engineers, and more.

Researching and adopting new technologies early to incorporate them into products is a regular practice for Intech teams, through online research, direct participation in international exhibitions and conferences, and field trips abroad.

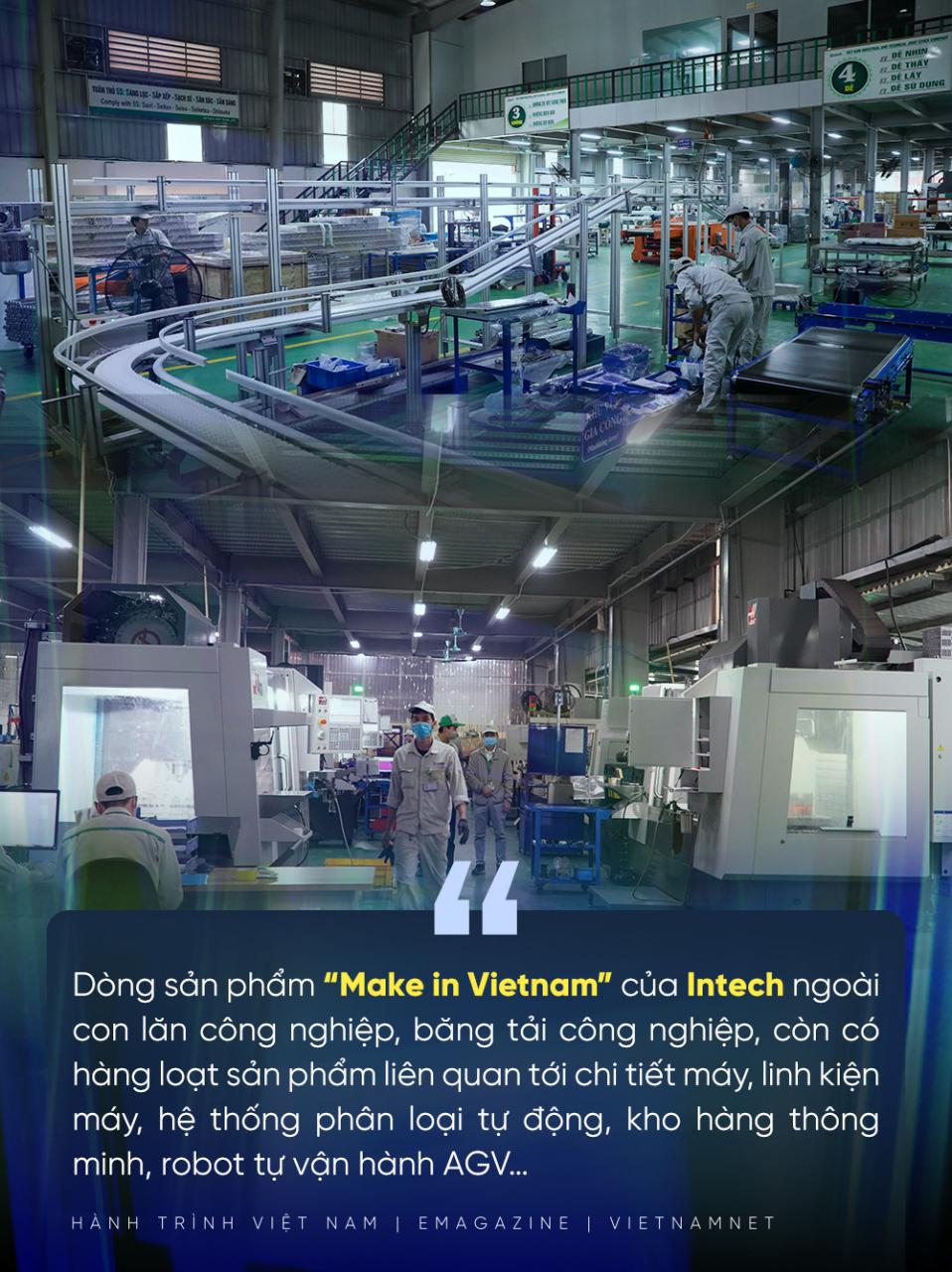

Intech's "Make in Vietnam" product line, in addition to industrial rollers and conveyor belts, also includes a range of related products such as machine parts, machine components, automatic sorting systems, smart warehouses, AGV autonomous robots, etc., all of which have proven their quality in the market.

“Vietnamese people keep buying products from China and abroad, while Intech is supplying those same products to overseas markets, including demanding ones. Earlier this year, the media reported on the inauguration of ABB Group's state-of-the-art factory in Bac Ninh, one of the most modern in Southeast Asia. All the production lines and automation systems in that factory were 100% supplied by Intech, from consulting and design to manufacturing and installation, a 'turnkey' solution. Many people, unaware of this, thought ABB brought its machinery and equipment from Europe,” Mr. Thang explained.

Currently, Intech is continuing to export its more technologically advanced products with higher intellectual content to overseas markets.

Recently, a Japanese partner placed an order for an automated parcel sorting system. Intech is currently manufacturing the system and expects to ship it from Vietnam to Japan in early 2024, with a team of experts sent to install it for the customer.

“We are also working with several European partners; however, for now, Japan will remain our focus market. Of course, if other international partners come along, we will serve them and meet their requirements to the best of our ability. We anticipate Japan, the US, and Europe to be Intech’s three key markets in the next five years,” Mr. Thang added.

To penetrate the Japanese market, the Intech team had to overcome many hardships. There were times when they felt exhausted, almost giving up. The slogan "Vietnam can do" became the motivation to regenerate energy and determinedly succeed.

The aspiration to bring Vietnamese products to the world was formed in the mind of the Chairman of Intech from his experiences attending international exhibitions and visiting factories abroad. Furthermore, statements like "Vietnam can't even produce a screw," or the assertion by partners that "Vietnam is just an underdeveloped country," touched the nationalistic spirit of Vietnamese entrepreneurs, making him increasingly determined to bring "Make in Vietnam" products to the international market as soon as possible, joining the Vietnamese business community in the global supply chain, and gradually changing the perception of the Vietnamese people and the country in the eyes of the world.

"The spirit of an entrepreneur is to dare to take risks, dare to think, dare to act, and if they have great and noble ideals, they will receive the consensus of the community and society," emphasized businessman Hoang Huu Thang.

Conquering international customers and markets is no easy feat. Besides the great ambition to establish Vietnamese brands and intellectual property, Mr. Thang noted that Vietnamese businesses need to pay more attention to specific issues, such as the trends in green and circular economies.

“In the very near future, if we don't meet greening standards in our supply chain—from greening businesses, greening factories, greening production systems, greening products…—we won't be able to supply goods to demanding, large markets like Europe, the US, and Japan… Although major partners aren't required to meet these standards right now, they will prioritize cooperation opportunities with businesses that meet the standards first. Vietnamese businesses and entrepreneurs must pay attention and prepare, otherwise they will be greatly affected,” Mr. Thang advised, adding that Intech plans to build a new factory in 2024, which will be a green factory.

Currently, Chairman Hoang Huu Thang affirms that Intech Group is a purely Vietnamese company, 100% owned by Vietnamese people, with no foreign elements. However, he also left open the possibility of future direction: “Many foreign partners have expressed interest in investing. We will carefully consider and choose the right partner to achieve breakthroughs, accelerate growth, and participate more deeply in the global supply chain.”

Article: Dawn

Design: Nguyen Cuc

Vietnamnet.vn

![[Photo] Prime Minister Pham Minh Chinh holds a phone call with the CEO of Russia's Rosatom Corporation.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765464552365_dsc-5295-jpg.webp&w=3840&q=75)

Comment (0)