Currently, Vietnam National Coal - Mineral Industries Group (TKV) is continuing to direct coal production and screening units to do a good job of recovering both rock and coal, arranging suitable dumping areas; at the same time, actively seeking new directions to propose to the province on the plan to sell mine waste rock outside the province. If this policy is implemented, a large amount of mine waste rock will be transported and sold outside the province, which means that TKV will save a lot of costs related to the current treatment and dumping work.

Deo Nai Coal Joint Stock Company is a large-scale open-pit coal mining unit of TKV (Vietnam Coal Corporation), with an average annual output of over 2.5 million tons of raw coal. "According to the technological process, to extract the aforementioned amount of coal, Deo Nai Coal will have to excavate and dispose of 19-21 million m³ of waste annually. "The amount of soil and rock is over 13 m³ /ton. That's not including the 300-500 tons of waste rock generated annually from screening and coal recovery from non-coal products. This leads to pressure on the scale of the waste disposal site, transportation costs, labor costs, and environmental costs..." - said Mr. Nguyen Ngoc Tung, Deputy Director of the company.

Not only Than Deo Nai, the volume of excavated and dumped soil and rock of coal industry units is getting larger and larger, due to the deeper and deeper mining area. Most open-pit mines have approached the mining depth of -200 to -300m compared to sea level. Preliminary calculations show that to mine one ton of coal, it is necessary to excavate 11-13 million m3 . rock and soil. Thus, on average, the amount of excavated rock and soil from the open-pit coal mining technology of TKV is approximately 150 million m³ per year.

Screening and consumption units also discharge a huge amount of processed stone and have to bear the pressure of dumping area and many related costs.

Cua Ong Coal Selection Company - the unit operating the largest coal screening and processing line system in the Group, on average, Cua Ong Coal Selection Company operates production with about 12-13 million tons of raw coal screened and processed each year and the amount of waste rock is up to more than 1.3 million tons. According to regulations, this type of waste rock is no longer usable and must be dumped into the planned waste dumps of the coal industry.

To handle this large volume of waste rock, Cua Ong Coal Selection Company has arranged a Transport workshop with modern and synchronous human resources, vehicles and equipment. And the Transport workshop is currently managing 38 locomotives of all types, over 640 wagons of all types and more than 500 employees operating 3 shifts/day. In addition, the Company is still managing and operating a waste rock transport system back into the mine, with the total volume transported from 2020 to present is more than 3 million tons of waste rock.

According to Mr. Nguyen Quang Hung, Deputy Director of the Company, currently, the transportation cost per ton of waste rock from the screening plant to the Dong Cao Son mine dump is about 60,000 VND/ton. Along with many related costs such as leveling and renting transportation routes, each year, the enterprise spends from 75-80 billion VND to "take the trash to the dump".

Over 1 billion cubic meters The amount of mine waste rock from production, screening, processing and consumption units currently stored at TKV's waste dumps has been a concern for many generations of coal industry leaders and Quang Ninh province. Previously, this amount of rock was only used to fill mining pits, improve waste layers, and restore the environment of coal industry units. However, the amount of mine waste rock processed in this way is still too small compared to the amount of waste rock currently stored at the dumps.

In 2017, a local enterprise, with the approval of the province and TKV (Vietnam Coal Corporation), used mine waste rock from the Dong Cao Son waste dump to produce artificial crushed sand, replacing natural sand. This also marked the first time a production line for processing sandstone into artificial sand was brought to Vietnam and installed at the large waste dump of the Cam Pha coal region – where approximately 32-36 million tons of waste rock from mines are generated annually, incurring significant costs for waste treatment.

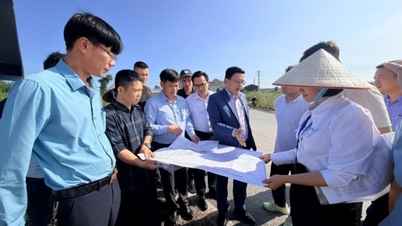

Continuing to implement the circular economic development strategy according to the policy of Quang Ninh province, since 2018, TKV has calculated the possibility of reusing mine waste rock and soil as filling materials for industrial and civil construction works in the area. After many efforts of the province and TKV, at the end of 2022, the Group started exploiting and recovering mine waste rock and soil to serve the filling of civil and industrial works in the South Pillar Waste Area - Suoi Lai Mine, Hon Gai Coal Company - TKV, with a recovered volume of 3.5 million m 3 .

However, the volume of mine waste treated in this direction is still limited, while every year, the Group's mining, screening and processing lines are still discharging hundreds of millions of m3 . rocks and soil.

Currently, in Quang Ninh province, only a few enterprises have agreed to buy waste rock from TKV as raw materials for the production of construction materials. To continue to find new directions for mine waste rock in Quang Ninh, TKV actively proposes and requests permission to sell mine waste rock outside the province to enterprises that need to use it as filling materials and construction materials. If this policy is soon approved, TKV will reduce a lot of the burden of costs and at the same time increase large revenue sources.

However, the relevant authorities and TKV will need to make strict commitments to ensure the processing, transportation and properties of mine waste rock when selling to businesses outside the province in need, avoiding risks of resource loss and loss of security and order during the implementation process.

Source

![[Photo] Closing Ceremony of the 10th Session of the 15th National Assembly](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765448959967_image-1437-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh holds a phone call with the CEO of Russia's Rosatom Corporation.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F11%2F1765464552365_dsc-5295-jpg.webp&w=3840&q=75)

![[OFFICIAL] MISA GROUP ANNOUNCES ITS PIONEERING BRAND POSITIONING IN BUILDING AGENTIC AI FOR BUSINESSES, HOUSEHOLDS, AND THE GOVERNMENT](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/11/1765444754256_agentic-ai_postfb-scaled.png)

Comment (0)