Hoa Phat Group is starting to negotiate, cooperate, support, transfer technology and techniques with partners and suppliers of steel rail production equipment for railways.

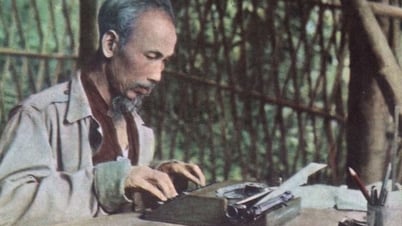

Chairman of Hoa Phat Group Tran Dinh Long and a group of technical staff went to study at Europe's leading rail manufacturing factory - Voestalpine (Austria). Photo: VGP

Technological readiness Talking to the Government Electronic Newspaper, Mr. Tran Dinh Long, Chairman of Hoa Phat Group, said that according to the quality classification table, steel for making ball bearings, valve springs, alloy springs, steel for making car tire belts... is difficult to 10, but steel for making high-speed train rails is only at level 8. "Hoa Phat Group's team of technology engineers has mastered the technology well to produce the most difficult, highest quality products such as steel wire for cold stamping, arc welding steel wire, steel for making elevator cables, weather-resistant steel plates in 2021, especially steel coils for making car tire belts (tirecord steel)", Mr. Long said. Steel for making tire belts has very high requirements for the purity of liquid steel. Steel belt fibers have a very small diameter of 0.15-1.80mm, like hair, the product needs to have special physical and mechanical properties, extremely high purity, and very low levels of gas impurities. Hoa Phat Dung Quat Steel has been refining this special steel since 2022 at Dung Quat 1's Rolling Line 3 and supplying it to Korean and Belgian partners. In addition, Hoa Phat has also been certified to supply raw steel for the production of elevator cables and crane cables for Japanese partners. As the only Vietnamese steel manufacturer capable of producing high-tech steel, Hoa Phat's Chairman affirmed that this enterprise ensures investment in equipment and technology transfer to produce the best and highest quality rail steel as Europe is producing. It is known that G7 partners supplying technological equipment to Hoa Phat such as Danieli, SMS... all hold the world's leading position in the production of rail steel in Europe and Asia. In addition, in order to have solid preparations for participating in the high-speed railway project, recently in October-November 2024, Chairman of the Board of Directors of Hoa Phat Group Tran Dinh Long and a team of technology experts directly went to learn about the reality at many of the world's leading steel rail factories in Europe; refer to the arrangement of technological equipment lines for the factory, the way of operating and organizing production, production technology processes, quality control processes throughout the entire process from preparing clean raw materials produced from iron ore, vacuum refining to refine the highest purity metal and remove harmful gas impurities, online quality control system, UT equipment to check for defects inside steel rails (Ultrasonic testing), laser geometric profile testing equipment (Hiprofile), rail straightening system, rail end tempering system in the process of producing rails for high-speed railways to ensure quality is always at the highest level. Hoa Phat Group is also starting to negotiate, cooperate, support, transfer technology and techniques with partners, suppliers of steel rail production equipment for railways, and they are all partners who have accompanied Hoa Phat for many years.

Hoa Phat Dung Quat Steel cooperates with the School of Materials - Hanoi University of Science and Technology to organize in-depth training on high-quality steel products (Steel for making car tire belts/belts; electrical steel (Silicon steel); steel for making rails for high-speed trains). Photo: VGP

Hoa Phat Dung Quat Steel also cooperates with the School of Materials - Hanoi University of Science and Technology to continuously organize intensive training courses on high-quality steel products with 3 main topics, focusing on special steel types and complex production techniques such as: Steel for making car tire belts/belts; electrical engineering steel (Silicon steel); steel for making rails for high-speed trains. Completing procedures to implement the high-speed rail steel project in Phu Yen In addition to the above preparations, Hoa Phat is also promoting the completion of necessary procedures to clear the land and implement projects in Hoa Tam Industrial Park, in the South Phu Yen Economic Zone, Phu Yen province. Including the investment project to build the Hoa Phat Iron and Steel Complex. The expected product structure of this Complex focuses on high-quality steel lines for mechanical engineering such as rail steel, steel plates, structural steel, shaped steel, and smooth round bars (SBQ). Immediately after having the site, Hoa Phat can be ready to implement the project of producing steel rails for high-speed railways, in terms of technology, human resources and production location. Source: https://baochinhphu.vn/hoa-phat-san-sang-bat-tay-vao-san-xuat-thep-duong-ray-cho-du-an-duong-sat-toc-do-cao-102241125085600234.htm

![[Photo] Party and State leaders visit President Ho Chi Minh's Mausoleum](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/d7e02f242af84752902b22a7208674ac)

![[VIDEO] - Enhancing the value of Quang Nam OCOP products through trade connections](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/17/5be5b5fff1f14914986fad159097a677)

Comment (0)