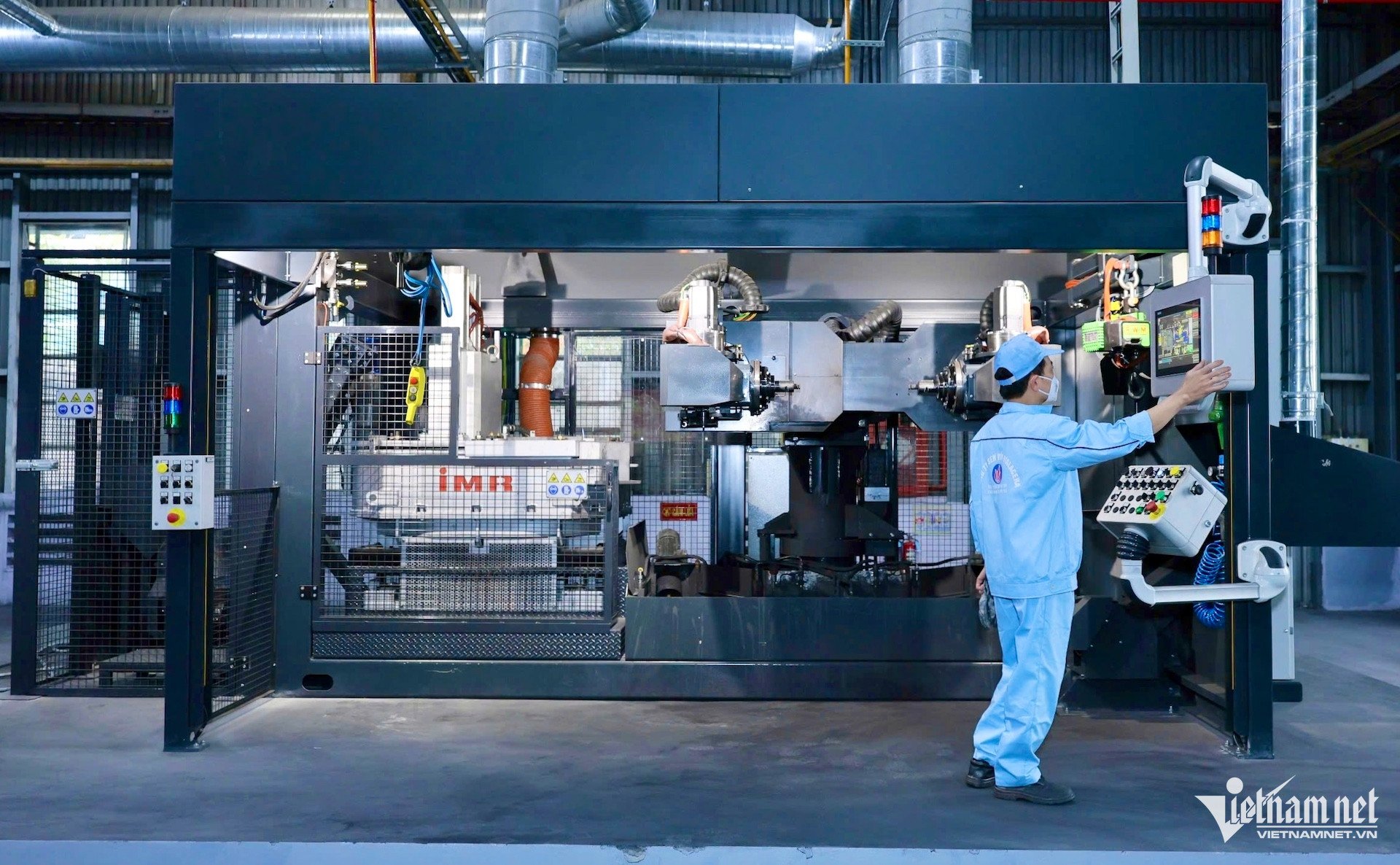

The 17th electric low pressure die casting machine system in the world is present at Viglacera faucet factory with PVD coating technology, marking the Vietnamese enterprise joining the group of faucet manufacturers possessing the most modern technology in the world.

Enhancing made in Vietnam products, expanding export opportunities

In early 2025, Viglacera Faucet Company - Branch of Viglacera Corporation - JSC has more "first-footing" guests, especially foreign experts guiding the transfer of many new technologies in the world.

Present at the Viglacera faucet factory (Hanoi), Mr. Luca Maghet, CEO of IMR Engineering & Technologies SRL (Italy), showed us the electric low pressure casting machine system that was just transferred to Vietnam at the end of 2024.

According to Mr. Luca Maghet, this is the 17th electric low pressure die casting system in the world. “With the progress in investing in this equipment system, Viglacera can completely join the group of pioneering faucet manufacturers, possessing the most modern technology in the world,” this director assessed.

Mr. Vu Hong Hung, Head of Technical Department of Viglacera Faucet Company, said that with 25 years of development, the production of faucets at the company is carried out through 5 stages: casting, mechanical processing, grinding, plating and assembly. In recent times, the company has applied many new technologies in all stages to improve production capacity.

For the casting process alone, in 2024, the company spent more than 600,000 Euros to own an Italian-technology electric low-pressure casting system.

“With the old casting line, workers had to manually pour bronze into the mold. This made the product quality completely dependent on the worker’s skills, and productivity was not high. Meanwhile, the electric low-pressure casting system helps Viglacera completely master high technology, helping the product achieve high purity, delicate and sharp surfaces, surpassing traditional gravity casting products.

This technology not only ensures consistent quality but also improves productivity, bringing prices to a reasonable level and opening up opportunities to produce products with sophisticated designs. This is an important factor that helps products become highly competitive, especially in the extremely rich and diverse shower faucet market today," Mr. Hung emphasized.

Not only investing in the "core" for shower products with higher smoothness and sophistication, in 2024, the company also pioneered investing in an Italian technology PVD vacuum coating system in Vietnam.

According to the leader of Viglacera Faucet Company, PVD coating technology requires a higher initial investment than the conventional plating method, and the implementation process also requires much more meticulousness and complexity. However, because it is closed in a fully automatic line, in addition to quality, it also creates a rich series of surface colors for shower faucets.

In particular, PVD coating technology also helps Viglacera shower products meet 3 criteria at the same time: green in production - green for the environment - green in use.

“The combination of these two newly invested technology systems, combined with the entire previous innovation process in mechanical processing stages, has created a complete faucet production line. Thereby, helping consumers access products that meet international standards at competitive prices. At the same time, expanding export targets to demanding markets such as North America and Europe,” said Mr. Hung.

Apply modern technology to break through

Emphasizing the trend of modern production, applying advanced, environmentally friendly technologies, to meet high technical and aesthetic standards in the faucet manufacturing industry, a representative of Viglacera Faucet Company revealed that after a period of effective operation of the new current technologies, the company will invest in converting the grinding stage to robots. It is expected to be implemented soon in 2026.

Mr. Nguyen Van Tien, Director of Viglacera Sanitary Ware and Faucet Department, said that to complete the development goal for 2025 and the vision for the next 5 years, Viglacera will focus on three core tasks.

First of all, invest heavily in production technology, especially in the shaping stages, apply automation and increase the proportion of mechanization to optimize quality and productivity.

Along with that, the company will promote commercialization through project and export channels, develop a distribution system with specialized pre- and post-sales consulting services to enhance customer experience.

At the same time, the company will also focus on developing product lines suitable for the characteristics of each region and market trends, prioritizing water-saving technology and smart devices for smarthomes, contributing to promoting the trend of modern and sustainable living.

“The technological mark demonstrates Viglacera’s breakthrough efforts in elevating “made in Vietnam” shower products to stand shoulder to shoulder with the world’s leading brands. Besides, it also affirms the enterprise’s determination to break through in the era of growing with the country,” Mr. Tien emphasized.

Mr. Ba Sam tells the story of high-tech shrimp farming, earning 50 billion VND per year

President Trump makes a series of decisions, the trade and technology war will be fierce

Binh Dinh Chairman inspects technology projects all evening

Source: https://vietnamnet.vn/dau-tu-cong-nghe-hien-dai-bac-nhat-dua-hang-made-in-vietnam-ra-the-gioi-2370177.html

![[Photo] National Assembly Chairman Tran Thanh Man meets with Thai Prime Minister Paetongtarn Shinawatra](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/e71160b1572a457395f2816d84a18b45)

![[Photo] Prime Minister Pham Minh Chinh receives Country Director of the World Bank Regional Office for Vietnam, Laos, Cambodia](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/15/2c7898852fa74a67a7d39e601e287d48)

Comment (0)