BHG - Recently, dried vermicelli has been favored by many people because of its convenience, ease of preservation and preparation in many dishes. Grasping that trend, the Dry Vermicelli Production Cooperative of Hong Minh village, Tung Ba commune (Vi Xuyen) has continuously improved the production process and enhanced the quality to bring dried vermicelli products to markets in and outside the province.

Currently, the Hong Minh Dry Vermicelli Production Cooperative, owned by Mr. and Mrs. Nong Thi Thuyet, is actively operating in Hong Minh village, Tung Ba commune. According to Ms. Nong Thi Thuyet, to make a batch of standard dry vermicelli, the production process must go through many meticulous stages.

|

| After pressing, the vermicelli will be dried naturally. |

First, the selected rice must be dry, spongy, have good expansion and not be too sticky to ensure that the vermicelli does not stick together when cooked. Rice varieties such as GS55, Bao Thai, Khang Dan, pure, locally grown, are considered the most suitable for producing dry vermicelli. After cleaning, the rice will be soaked for 6-8 hours to soften, then ground into fine powder. The milling process requires high technique because just a small error in the ratio of water and powder can affect the toughness and evenness of the vermicelli.

After grinding, the powder will be mixed with enough water to form a smooth paste, then put into a press to create noodles. The size and thickness of the noodles can be adjusted according to market requirements; the noodles after pressing are still moist, so they must go through the incubation and natural drying process. Local people still maintain the traditional drying method on bamboo racks for about a day to ensure the dried noodles meet the standards, are easy to preserve and can be used for a long time.

|

| Dried vermicelli is combined with ingredients such as purple pandan leaves for purple color and gac fruit for orange-red color. |

One of the special features of dried vermicelli is that it does not use chemicals or preservatives. To create natural color for vermicelli, people use ingredients such as purple pandan leaves for purple color, and gac fruit for orange-red color, which is both beautiful and retains the traditional flavor. It is the carefulness and meticulousness in each stage of production that helps Tung Ba dried vermicelli have superior quality compared to many other types of vermicelli on the market.

Thanks to the application of modern technology combined with traditional production methods, Hong Minh dried vermicelli products have full labels and barcodes to trace their origin, creating trust for consumers. On average, the facility consumes 400 - 500 kg of dried vermicelli per day, creating stable jobs for 3-5 local workers with an income of about 5 million VND/person/month.

|

| Currently, Hong Minh dried vermicelli products have full labels and barcodes to trace their origin. |

Mr. Vi Huu Quynh, Vice Chairman of Tung Ba Commune People's Committee, said: "In the coming time, the commune will find ways to expand the dry vermicelli production model, support households to invest in machinery, and improve product quality to meet market demand. At the same time, the commune will also create conditions for Tung Ba dry vermicelli products to access many large consumption channels, contributing to economic development and increasing people's income."

With guaranteed quality and the right direction, dried vermicelli in Tung Ba commune not only contributes to preserving traditional crafts but also opens up opportunities for economic development and increasing income for local people. We believe that with a strict production process and support from the government, this product will increasingly be trusted by many consumers, promising to go further, becoming a famous specialty of Ha Giang in general and Tung Ba commune in particular.

Article and photos: Hong Cu

Source: https://baohagiang.vn/kinh-te/202503/dac-san-bun-kho-truyen-thong-o-tung-ba-22a5326/

![[Photo] General Secretary To Lam receives First Deputy Secretary General of the African National Congress (ANC) of South Africa](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/20/bb2999907e1245d5b4c7310a890d8201)

![[Photo] Vietnamese shipbuilding with the aspiration to reach out to the ocean](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/20/24ecf0ba837b4c2a8b73853b45e40aa7)

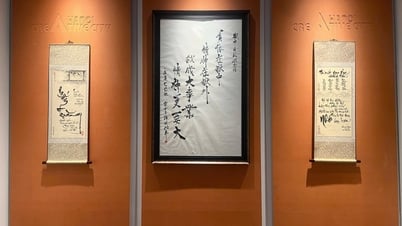

![[Photo] Award ceremony for works on studying and following President Ho Chi Minh](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/20/a08ce9374fa544c292cca22d4424e6c0)

![[VIDEO] - Enhancing the value of Quang Nam OCOP products through trade connections](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/17/5be5b5fff1f14914986fad159097a677)

Comment (0)