South Korea is one of the Asian countries that invested in and developed high-speed rail early on, and is famous for its KTX trains.

From a controversial project...

When talking about high-speed rail in South Korea, it's impossible not to mention the country's first high-speed rail line - the KTX (Korea Train Express).

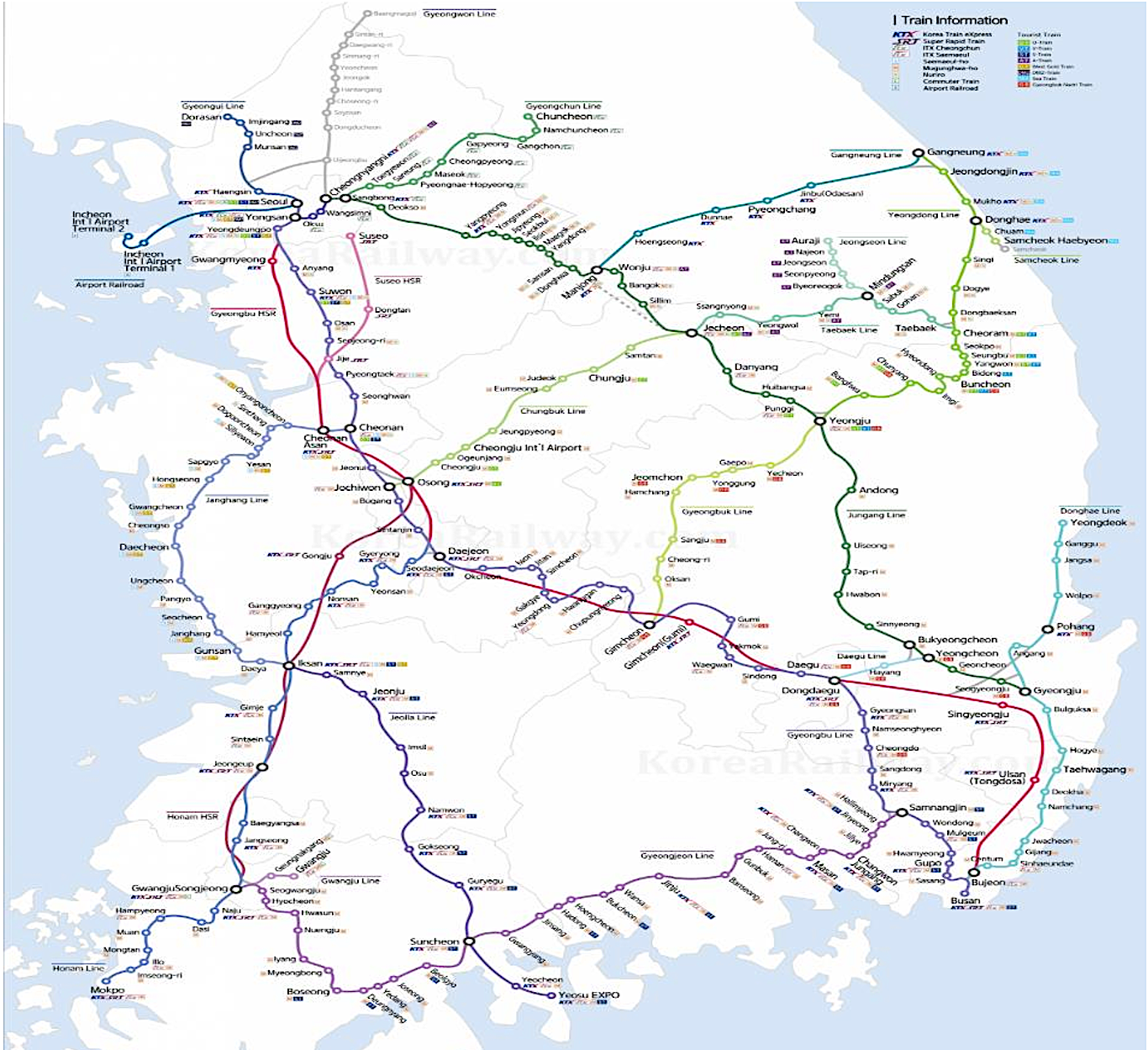

Map of South Korea's high-speed rail network.

In his inaugural speech on March 30, 2004, then-Acting President of South Korea, Goh Kun, emphasized that " the world has entered an era where speed is one of the most important factors determining competitiveness." He added, "High-speed rail is a symbol of national competitiveness and the foundation of national prosperity in the 21st century."

It should be noted that, at that time, the opening of this railway line (Phase 1 connecting Seoul and Busan) officially made South Korea the 5th country in the world to successfully build a high-speed rail line, behind only Japan, France, Germany, and Spain.

Traveling at 300 km/h, South Korea's high-speed train can transport passengers from Seoul to Busan in just 2 hours and 40 minutes, and from Seoul to Mokpo (South Jeolla Province) in 2 hours and 58 minutes, saving 1 hour and 30 minutes and 1 hour and 40 minutes respectively compared to traveling by regular train.

The advent of the high-speed rail era has enabled Koreans to travel anywhere in the country in just half a day. This has led to a revolution in lifestyles, allowing people to overcome limitations of time and space.

Seoul and other locations have become closer, and even people living in the South and North Chungcheong provinces in central South Korea can easily and conveniently commute to work at companies in the capital.

Few people know that the high-speed rail project, which helped South Korea gain prestige in the world, initially faced difficulties, if not outright controversy.

Choi Jin-suk, director of the Railway Transportation Center at the Korea Transport Research Institute, said: "When this plan was first introduced, there was a lot of opposition."

The reason is that the Saemaul train then took about 4 hours and 50 minutes to travel from Seoul to Busan. Introducing these high-speed trains would reduce the travel time to 2 hours and 30 minutes; however, this would require a massive investment of billions of USD.

Many transportation experts have argued that it is a waste of money to spend such a large sum just to reduce travel time by two hours.

Conversely, proponents argue that one of the most valuable and scarce resources for humankind is time.

Saving time also brings industrial and economic benefits. This is especially true during a time when the economy is growing rapidly.

...to the world's leading high-speed rail nation

The construction process for South Korea's first high-speed rail line was lengthy and relatively difficult.

The Seoul-Busan railway project took 12 years to complete, involving 30,000 workers and costing 12 trillion won (equivalent to 10.5 billion USD at current exchange rates).

In 2004, South Korea inaugurated its first high-speed rail line, the 417km Seoul-Busan line. That same year, the 374km Seoul-Mokpo line was also opened. The KTX (Korea Train Express) high-speed train, the fifth fastest in the world, operates at speeds exceeding 300km/h. From this point on, South Korea joined the ranks of countries with advanced railway systems worldwide.

After about 20 years, South Korea has a high-speed rail network consisting of 8 lines, with a total length of 873km and a maximum operating speed of 300km/h, exclusively for passenger transport. The goal is to increase the speed to 400km/h by 2040.

Since then, South Korea's high-speed rail network has continuously expanded and been newly constructed. By September 2023, South Korea had 1,644 high-speed trains (KTX, KTX-Sancheon, KTX-EUM, SRT), operating 375 trains per day, with an on-time performance rate of 99.8%; the number of passengers transported reached 225,000 per day, the average distance traveled per passenger was 225.4 km, and the occupancy rate ranged from 61.6% to 89.2% of passengers who booked tickets through mobile applications.

In South Korea, the high-speed rail system is dedicated to passenger transport with a maximum design speed of 350 km/h. Traditional railway lines, on the other hand, are used for freight and passenger trains, with a maximum design speed of 150 km/h.

South Korea did not design a shared high-speed rail line due to concerns about the time lost from stopovers and the impact on the signaling and communication systems.

However, high-speed trains can still operate on traditional railway lines, but they only stop at main stations along the line and do not stop to pick up or drop off passengers. There are only 5-10 or fewer high-speed passenger trains per day on these railway lines.

Regarding technology, according to research by the Transport Newspaper, this country selects, applies, and then develops its own technology based on technology transfer.

Notably, South Korea even began building infrastructure before making a final decision on technology selection. The infrastructure elements in Phase 1 had to be capable of supporting all types of technology.

After considering three of the most advanced high-speed rail technologies at the time – German technology with the ICE-2 train generation (280km/h), French SNCF (TGV) with the TGV Atlantique train generation (300km/h), and Japanese technology with the Shinkansen 300 train generation (270km/h) – South Korea decided to choose France.

KTX high-speed train (Photo: internet).

The reason was that France made a strong commitment to transferring technology to South Korea, while Germany and Japan did not . This was one of the decisive factors in South Korea's choice of TGV technology for its high-speed rail system.

For the first Seoul-Busan high-speed rail line, the first 12 trains out of a total of 46 were manufactured in France and assembled in South Korea, while the remaining 34 trains were manufactured and assembled in South Korea. Hyundai Rotem was selected as the company to receive the technology for manufacturing locomotives and carriages, and began phased production starting in 2001. The trains manufactured in South Korea are designated as the KTX-1 generation.

Regarding the scope of technology transfer, it includes all the necessary components and parts to set up production lines for vehicles, assembly, carriages, and control systems; providing technical specifications for 29 items, along with 350,000 technical documents, and training and support for 2,000 technicians.

During this period, the 13th KTX train was the first train manufactured in South Korea and was completed in 2002; by 2003, the 46th train was completed, marking the first instance of technology localization in South Korea.

Thus, five years after completely manufacturing the first two trains, South Korea has achieved a 93.8% localization rate for its vehicles.

To achieve the goal of successful technology transfer, from 1996 to 2002, South Korea implemented the High-Speed Rail Technology Development Project. The Ministry of Land, Infrastructure and Transport of South Korea played a central role, with participating ministries including the Ministry of Trade, Industry and Energy, and the Ministry of Science and Technology; the project was managed by the Korea Railway Research Institute. The project involved 4,934 researchers from 129 organizations and units, including 82 businesses, 18 research institutes, and 29 universities.

With its advancements in science and technology, South Korea subsequently developed the KTX-2 generation of trains, building upon and adapting features from the KTX-1 generation. The Korean trains fully embody the characteristics of the original TGV trains, utilizing a centralized propulsion system and a GSM communication system.

In 2021, Korea Railway Corporation (KORAIL) launched five new KTX EMU-250 high-speed trains with a speed of 260 km/h on the Seoul-Gyeongju Jungang line. These are the first high-speed trains using distributed propulsion technology to operate in South Korea. The EMU-250 was developed based on the HEMU-430X, a prototype train with a speed of 430 km/h designed by Hyundai Rotem in 2012.

Thanks to the application of distributed propulsion technology, even if a problem occurs in one part, the ship can still operate safely.

The trains are also expected to improve energy efficiency and reduce wind resistance. This will allow South Korea to cut greenhouse gas emissions from 235,000 tonnes in 2019 to 165,000 tonnes by 2029.

Currently, 87.5% of centralized train control (CTC) systems allow KORAIL to inspect and monitor actual train operations, preventing potential accidents.

Source: https://www.baogiaothong.vn/cuoc-cach-revolution-of-the-speed-of-korea-railway-192241122001946556.htm

![[Photo] Signing ceremony of cooperation documents between Vietnam and Cambodia](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2026%2F02%2F06%2F1770364590364_vna-potal-le-ky-cac-van-kien-hop-tac-giua-hai-nuoc-viet-nam-campuchia-8577065-1695-jpg.webp&w=3840&q=75)

Comment (0)