Norway is one of the leading countries in promoting technological solutions to collect and recycle plastic waste, thereby addressing the problem of plastic waste at sea, which many coastal countries can learn from and apply.

|

| Norway focuses on investing resources in fighting ocean plastic pollution. (Source: Earth.com) |

On average, we dump 12 million tons of plastic into the ocean every year. Plastic breaks down into microscopic plastic particles, enters the stomachs of marine creatures, and accumulates in the marine food chain.

As a country with a long coastline, Norway has been aware of the harmful effects of plastic waste on the seas for a long time and has always invested a lot of resources in fighting plastic pollution in the ocean. Most of the technological solutions come from the private sector, where Norwegian companies are focusing on developing technological solutions to clean up the ocean and deal with plastic pollution.

Using technology to collect

Plastic waste must be collected before it sinks to the seabed or before weather, wind and sun break it down into microplastics. Collecting floating waste in the ocean is much more complex than collecting waste on land.

Using divers would be risky, due to the sea pressure and the hours of work. Not to mention that many of the seas off Norway have very harsh weather conditions, with big waves, strong winds and low temperatures.

Therefore, many Norwegian companies prioritize designing and manufacturing devices or technological solutions to clean the ocean and collect plastic waste at sea.

|

| Ocean Front's garbage collection vessel Natural Seabed. (Photo: Kim Anh) |

For example, OceanFront AS’ Natural Seabed Solution provides an environmentally friendly, comprehensive and sustainable marine debris cleanup service without the need for divers. It can contribute to the cleanup of both large and small objects, including shipwrecks. The Natural Seabed Solution was recently used to collect over 100 tonnes of marine debris in the Oslofjord and 84 tonnes of debris in Store Lungegårdsvann, Bergen.

Marine plastic waste originates from land-based sources, so collection solutions aim to increase the circularity of plastic and give it a new life.

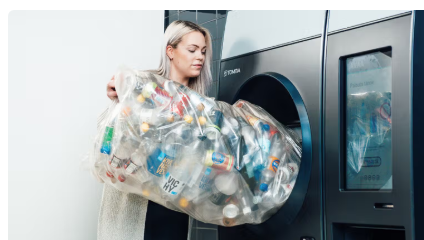

In 1972 TOMRA invented the first Reverse Vending Machine (RVM) to help a local grocery store in Norway collect used bottles.

With this invention, customers can return used bottles to get back their deposit (deposit and return). Since then, TOMRA has spent more than 50 years improving sensor-based collection and sorting technology, aiming to recover valuable materials from almost all types of waste, thereby promoting the transition to a green - circular economy .

|

| TOMRA's plastic bottle exchange machine. (Photo: Kim Anh) |

Each year, TOMRA's system collects more than 40 billion used cans and bottles, providing retailers and customers with an efficient way to collect, sort and process these materials.

TOMRA and other companies' solutions have helped Norway become a pioneer in the return of used plastic bottles. 95% of plastic bottles are returned in this way.

Recycling plastic waste

Plastic is so simple and cheap to produce that it is easy to throw away plastic products and packaging after a single use, creating huge amounts of plastic pollution. But what if we could give plastic waste a new “lifecycle”?

Norway promotes useful applications to increase the circularity of plastic products: recycling, reusing or even repurposing them, preventing them from being discarded into the environment and becoming plastic waste in the ocean.

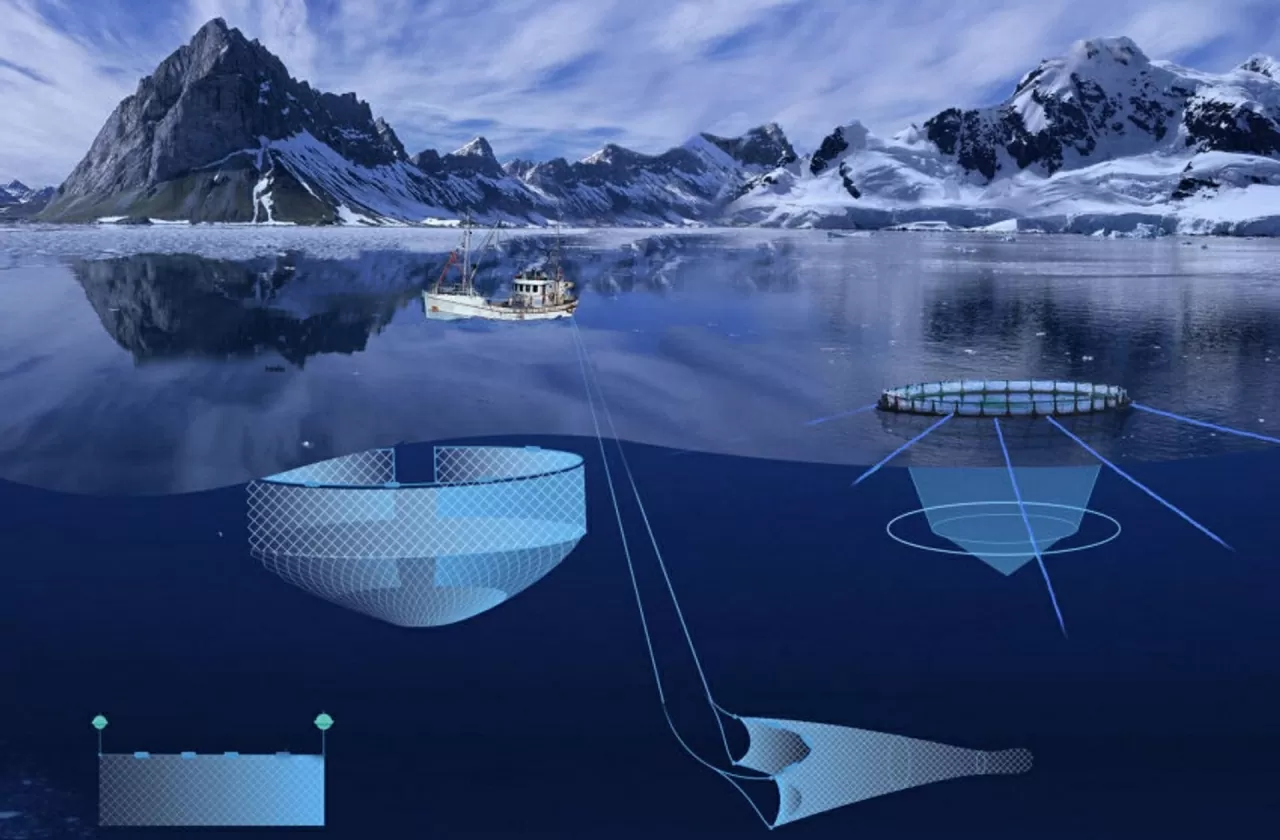

Nofir, another Norwegian company, focuses on collecting discarded marine aquaculture equipment such as nets and ropes. Discarded nets and ropes are often burned, buried, left at sea, or thrown back into the environment. In the long term, this poses a threat to humans, marine life, and the marine environment.

While large waste collection units only focus on collecting the usable parts of the waste, leaving the rest behind because they do not have the resources to process them. But Nofir’s solution is like killing two birds with one stone: collecting plastic waste while promoting new methods of plastic recycling.

|

| Nofir focuses on collecting discarded equipment in the marine aquaculture industry such as nets or ropes. (Photo: Kim Anh) |

Every year, Nofir’s system collects around 7,000 tonnes of raw materials for the recycling industry. At the same time, Norfil’s staff also supports recycling centers in turning this waste into econyl fiber – a product that can be used in the garment, textile, carpet manufacturing or other applications. In doing so, Nofir indirectly supports the reduction of textile pollution and limits the amount of waste in the ocean.

The role of research units

Norway prides itself on its multi-stakeholder approach and partnerships between government, industry and research institutes in finding solutions to national and global problems.

To tackle the problem of plastic waste in the marine aquaculture industry, ocean researchers at the Norwegian Organisation for Scientific and Industrial Research (SINTEF) are investigating the use of biodegradable materials to replace plastic nets, thereby reducing ocean plastic pollution.

So far, the results have been promising. While fishing trials have shown slightly less fish catch than traditional nylon gillnets, the environmental benefits are huge. Similar efforts to reduce plastic pollution and marine debris are needed to continue the fight against plastic in the ocean.

Source: https://baoquocte.vn/cong-nghe-lam-sach-rac-thai-nhu-o-bien-dang-ne-cua-na-uy-307289.html

![[Photo] Close-up of heavy damage at the school located on the banks of the Ban Thach River](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F26%2F1764152130492_ndo_bl_img-8188-8805-jpg.webp&w=3840&q=75)

![[Photo] VinUni students' emotions are sublimated with "Homeland in the Heart: The Concert Film"](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F26%2F1764174931822_10-3878-jpg.webp&w=3840&q=75)

![[Photo] Opening of the 28th Session of the Hanoi People's Council](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/11/26/1764155991133_image.jpeg)

Comment (0)