Preventing water bursts is one of the important tasks of the Vietnam National Coal and Mineral Industries Group (TKV), especially during the rainy season. This year, TKV's coal production and business activities are being affected by complicated weather conditions, with a higher number of rainy days and total rainfall than usual. The Group and its units have strengthened the prevention of water bursts and control of water flow in the mines, with the goal of ensuring safety for people and production areas.

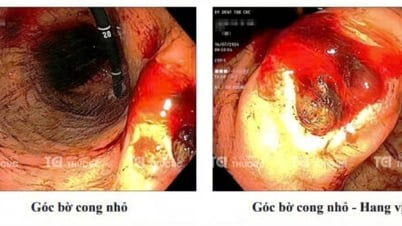

One of the potential difficulties of coal production units is the problem of water exposure in underground mines, which is determined from many different sources. These can be water-containing areas on the surface of the terrain such as: Rivers, streams, ponds, lakes, open-pit mines, waste dumps that are in operation or have ceased operation, subsidence and cracking areas. Notably, underground water-containing areas such as: Water-containing strata, geological boreholes, exploited areas, old and fractured mine systems; overlapping mining areas between open-pit - underground units, underground - underground units. Water seepage causing water bursts in underground mines is also one of the main causes of occupational accidents in the coal industry in the world and Vietnam.

Labor hero Nguyen Van Tia was one of those who witnessed the "life-threatening" moment of Than Mao Khe when the mine suffered a water leak in 2000. "The incident caused nearly 80m3 of "Water poured down the mine, causing the entire hydraulic support system worth 4 billion VND to collapse. Thanks to our continuous rescue efforts, we were able to save the mine and ensure the safety of people and the support system," Mr. Tia recalled.

In later stages, when coal mining technology was increasingly developed, the risk of water bursting was better prevented and controlled at Mao Khe Coal. However, with the specific complex nature of geological mirrors, this is still a difficult problem for the unit.

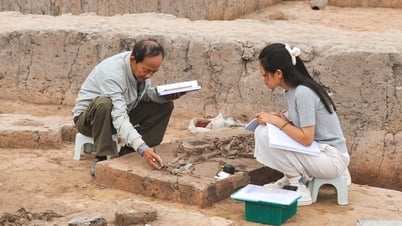

To ensure that prevention work is always one step ahead, geological exploration steps and identification of water-bearing objects are meticulously carried out by the unit using many methods. Based on the annual exploitation plan and on the basis of hydrogeological - engineering geological documents, and updated exploitation status, the unit will identify and delimit water-bearing objects, thereby developing solutions to ensure safety in production.

Thong Nhat Coal Company is also one of the large underground coal mines in Cam Pha area. In addition to geological difficulties, Thong Nhat also has to face special pressures from water-bearing strata. In the context of increasingly deep production areas, complex geology that is difficult to explore in detail, and increasingly extreme stormy weather conditions, the issue of controlling risks from water-bearing strata is of special concern to the unit.

Regarding surface water, Thong Nhat Coal is coordinating with open-pit coal mining units above the unit's underground production area, namely Deo Nai - Coc Sau Coal Joint Stock Company and Khe Sim Company, to organize the leveling of terrain at risk of subsidence and cracking, ensuring that no water accumulates on the surface. For underground production areas, the unit tightens detailed measures on exploration, drilling, and water separation to ensure safe working conditions.

Mr. Vu Huu Tuyen, Head of Mining Engineering and Technology Department, Thong Nhat Coal Company said: Every year, we plan and implement the TKV project, then issue it within the company to carry out the exploratory drilling step with long and medium-range boreholes. According to the plan assigned by TKV, in 2024, Thong Nhat Coal will carry out approximately 4,000m of drilling. In addition, the unit also organizes to review production areas at risk of containing water for additional drilling.

"In the measures to prevent and eliminate the risk of water bursts, water drainage drilling is one of the most important tasks. According to experience, during the process of mining or constructing underground mines, when cracks or locations with water leakage from the mine mirrors are detected, it is very likely that the mining system is gradually approaching water pockets, potentially posing a risk of water bursts. The immediate thing to do is to drill for water drainage to ensure safety. In the 2024 plan, TKV will carry out over 48 thousand meters of water burst prevention drilling," added Mr. Do Manh Cuong, Head of TKV Mine Engineering and Technology Department.

According to the forecast of the National Center for Hydrometeorology, the storms and rains in the remaining months of 2024 tend to increase in frequency, intensity, and unpredictable developments. To proactively prevent the risk of water bursting, the Chairman of the Board of Directors and General Director of TKV requested units to focus on reviewing and checking the terrain surface above the mining and tunneling areas to promptly detect and organize the leveling of cracks and subsidence, especially areas under mining tunnels... to minimize surface water intrusion. Underground coal mining. The Group also specifically requires underground coal mining units that exploit thick seams and recover top coal to review the terrain; in which, if there is water seepage, mining must be stopped to conduct exploratory drilling.

From 2020 to now, TKV has been granted 4 Exploration Licenses and 9 Exploration Projects to upgrade reserves within the scope of the Exploitation Licenses by the Ministry of Natural Resources and Environment. Accordingly, the volume of exploration boreholes carried out to serve the hydrological measurement of these licenses and projects is 27 boreholes/16,605 meters of drilling. The boreholes are being constructed to ensure the progress of the licenses and exploration projects.

Not only ensuring detailed and meticulous drilling work, units need to regularly update the water level at hydrological monitoring boreholes to assess the scale and level of impact of water-bearing objects, on that basis, take measures to drain to ensure safety for the production area; ensure the capacity of drainage pumping stations in the mine; deploy plans to prevent mine flooding during the rainy and stormy season. In addition, TKV also urgently reviews the overall management process and technological conditions, and continues to propagate, improve the skills and awareness of staff and workers about water burst prevention.

Source

![[Photo] General Secretary To Lam and international leaders attend the parade celebrating the 80th anniversary of the victory over fascism in Russia](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/9/4ec77ed7629a45c79d6e8aa952f20dd3)

![[Photo] Prime Minister Pham Minh Chinh chairs a special Government meeting on the arrangement of administrative units at all levels.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/9/6a22e6a997424870abfb39817bb9bb6c)

![[Photo] Russian military power on display at parade celebrating 80 years of victory over fascism](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/9/ce054c3a71b74b1da3be310973aebcfd)

![[Photo] Magical moment of double five-colored clouds on Ba Den mountain on the day of the Buddha's relic procession](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/9/7a710556965c413397f9e38ac9708d2f)

Comment (0)