(HNMO) - Southern scientists have successfully researched processes to turn wastewater and polluted water into useful products such as biodegradable plastic beads and water-filtering plastic beads.

Bioplastic from wastewater

This is a scientific research project carried out by a research group from the Institute of Environmental and Energy Technology (Saigon University) with the support of the Department of Science and Technology of Ho Chi Minh City. This city-level scientific task is called: "Research on the ability of bacteria to synthesize PHB resin from carbon-rich wastewater".

The content of the task aims to utilize the source of wastewater rich in hydrocarbon nutrients (especially present in wastewater from production facilities - food processing plants, paper factories, beer factories...) to develop microorganisms capable of synthesizing PHB, combining the PHB synthesis process with the wastewater treatment process.

“PHB bioplastic obtained from two strains of bacteria, Bacillus pumilus NMG5 and Bacillus megaterium BP5, can be considered a green, environmentally friendly material, suitable for use in daily life. Products made from this bioplastic have the same toughness as conventional plastic, but can completely decompose within 30-50 days depending on the environment,” said Dr. Ho Ky Quang Minh, head of the project.

Specifically, the team collected activated sludge and wastewater samples from the equalization tank of the wastewater treatment system at vermicelli, rice noodle and rice paper production facilities in Cu Chi district (Ho Chi Minh City), Mekong Food Company (Duc Hoa district, Long An province), Saigon Paper Factory (Tan Thanh district, Ba Ria - Vung Tau province), Minh Hung Paper Factory (Binh Phuoc province)... The results obtained 9 sludge samples and 9 wastewater samples with a total of 185 different bacterial strains.

Among these, there are 2 bacterial strains with the remarkable ability to synthesize PHB at 48 hours of culture: Bacillus pumilus NMG5 reaching 42.28% dry weight and bacillus megaterium BP5 reaching 41.19% dry weight. The group created PHB films from the synthesis of the above 2 bacterial strains, incubated in a moist soil environment. As a result, after 6 weeks, the films were completely decomposed. In a water environment, the films completely decomposed in 4 weeks.

From this very positive result, Director of the Department of Science and Technology of Ho Chi Minh City Nguyen Viet Dung said that the Department is considering the research team's proposal to continue supporting the implementation of PHB trial production on a larger scale, thereby completing the identification of bacterial strains and the synthesis process into biodegradable plastic particles to produce environmentally friendly packaging on an industrial scale.

From alum filtered water to water filter resin

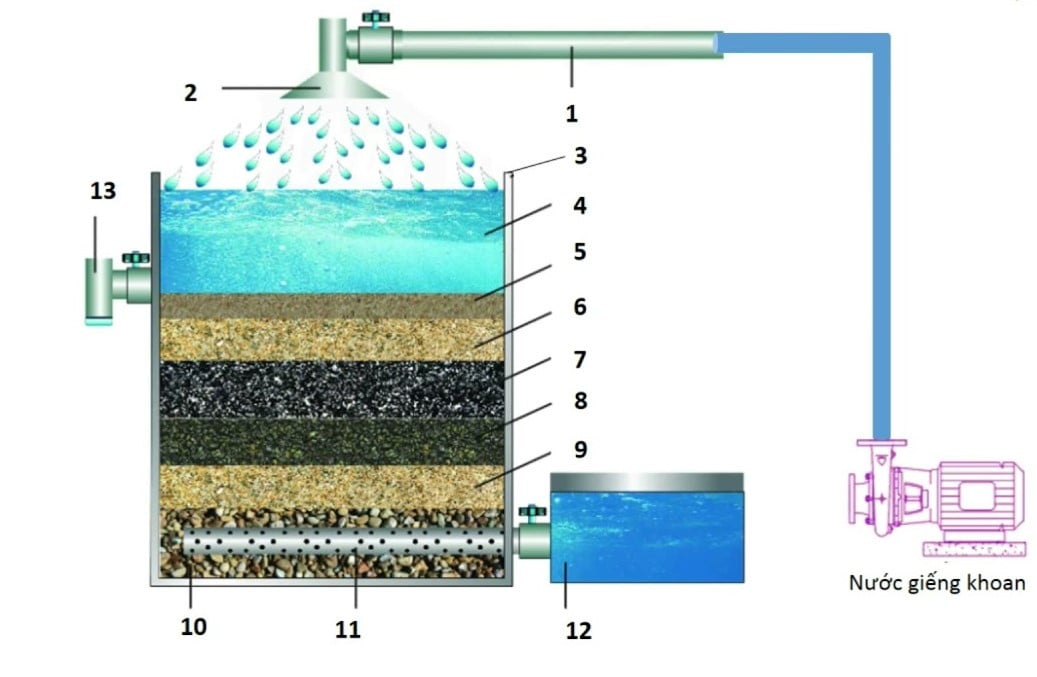

Based on the fact that nearly 50% of the people in the Mekong Delta are having to filter alum water into drinking water; along with that, 1 million hectares out of a total of more than 4 million hectares of land in the region is alum-contaminated land, the research team of An Giang University (Ho Chi Minh City National University) has implemented a scientific research project to utilize alum-contaminated water to create a plastic material - iron alum oxide that can simultaneously treat phosphate, calcium and magnesium in water.

According to Associate Professor, Dr. Nguyen Trung Thanh, representative of the research team, for a long time, people in the Mekong Delta have used many methods (using ash, lime, ion exchange resin, etc.) to treat alum water, then dispose of the waste, keeping the water clean. However, the waste after filtration has the risk of polluting the soil and water sources.

Meanwhile, alum can be synthesized into a filter material to remove phosphate in wastewater, avoiding pollution sources. "Therefore, we researched a process to both filter alum water to serve people's lives and have a material to wash away alum, eliminating pollution to soil and water sources," said Mr. Nguyen Trung Thanh.

In 2022, the group successfully researched and applied the use of ion exchange resin (225H) which is readily available on the market to maximally absorb iron in alum water during filtration. These resin beads then undergo a series of treatment processes and become a new material, hydrated iron oxide resin. When used as a water filtration material, this resin bead can simultaneously remove many other components of polluted water containing phosphate, calcium, magnesium, etc.

Fortunately, the results of water quality testing after filtration all meet the National Technical Regulation on surface water quality (QCVN 08-MT: 2015/BTNMT) for domestic water.

Building on the achievements, from the beginning of 2023 until now, the group is continuing to conduct tests at a number of households to perfect the process of creating plastic materials that, when filtered, can automatically change the state of many types of polluted water, without having to create separate types of filter plastic beads for each type of water with different pollutants.

Along with that, the research team reduced the cost of this filter material to suit the scale of mass use in households; researched the creation of plastic beads that "absorb" waste into nutrients for hydroponic plants; and perfected the regeneration process for reuse of plastic beads - hydrated iron oxide.

Source

![[Photo] Prime Minister Pham Minh Chinh chairs conference to promote public investment growth momentum](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/20/7d1fac1aef9d4002a09ee8fa7e0fc5c5)

Comment (0)